Steel Billet in Square Straight Form Big Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Billet in Square Straight Form Big Sizes Description:

Steel billet in square straight form big sizes is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, steel billet in square straight form big sizes is still in the form of a metal bar or rectangle. Small sizes of steel billet in square straight form big sizes are used in ship building.

2. Main Features of Steel Billet in Square Straight Form Big Sizes:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

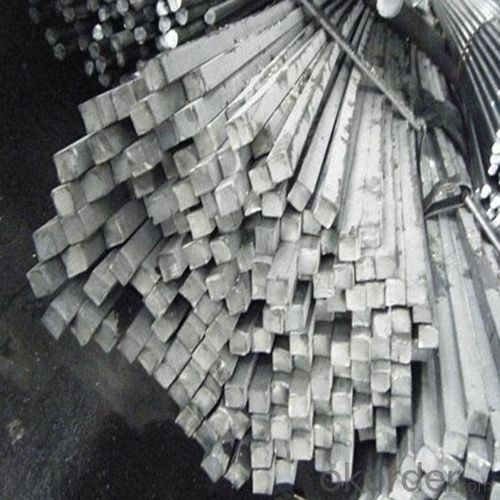

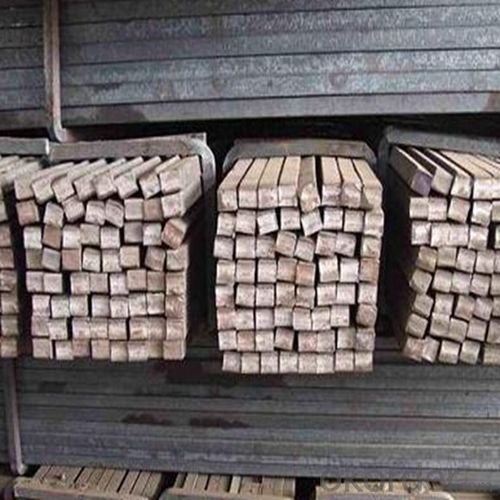

3. Steel Billet in Square Straight Form Big Sizes Images:

4. Steel Billet in Square Straight Form Big Sizes Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can a steel square be used for measuring the thickness of sheet metal?

- No, a steel square cannot be used for measuring the thickness of sheet metal as it is primarily used for checking right angles and measuring lengths or angles, not for measuring thickness.

- Q: Can a steel square be used for marking and cutting wood?

- Yes, a steel square can be used for marking and cutting wood. A steel square is a versatile tool that is commonly used in woodworking for measuring, marking, and checking the accuracy of right angles. It is typically made of high-quality steel and has a long blade and a shorter tongue that form a 90-degree angle. The long blade can be used to mark straight lines on wood, while the shorter tongue can be used to mark perpendicular lines. Additionally, the edges of a steel square can also be used as a guide for making straight cuts with a saw. Overall, a steel square is an essential tool for any woodworker and can be effectively used for marking and cutting wood.

- Q: Can a steel square be used for shelving installation?

- Yes, a steel square can be used for shelving installation. A steel square, also known as a framing square or carpenter's square, is a versatile tool that is commonly used in construction and woodworking projects. It is typically made of steel and has two arms that meet at a 90-degree angle, forming a right angle. This right angle can be used to ensure that shelving units are installed level and square. The steel square can be used to mark and measure the placement of brackets or supports, ensuring that they are properly aligned and evenly spaced. Additionally, the straight edge of the steel square can be used to check for straightness and alignment of the shelves themselves. Overall, a steel square is a reliable tool that can assist with the accurate and precise installation of shelving units.

- Q: Can a steel square be used for measuring and marking compound miter cuts?

- Yes, a steel square can be used for measuring and marking compound miter cuts. However, it may not be the most precise tool for this task. A combination square or a miter square would be more suitable for accurately measuring and marking compound miter cuts.

- Q: Can a steel square be used for checking the squareness of floor tiles?

- Yes, a steel square can be used for checking the squareness of floor tiles. Its straight edges and right angles can help determine if the tiles are properly aligned and perpendicular to each other.

- Q: What are the common misconceptions about using a steel square?

- Using a steel square can lead to confusion or incorrect assumptions due to a few common misconceptions. One such misconception is that a steel square is solely utilized for measuring right angles. While it is true that a steel square is commonly employed for this purpose, it can also be used for a range of other tasks, including measuring and marking angles that are not 90 degrees. Another misconception is that only carpenters or construction workers make use of a steel square. Although it is indeed a valuable tool in these professions, anyone who deals with measurements and angles can benefit from using a steel square. It is applicable to DIY projects, woodworking, metalworking, and various crafts or hobbies. Some people may also assume that using a steel square is complicated or requires advanced mathematical knowledge. However, this is not the case. With a basic understanding of its components and functions, anyone can easily learn how to utilize a steel square. Beginners can find plenty of online tutorials and guides to assist them in getting started. Lastly, some individuals may believe that a steel square is an outdated or obsolete tool in the era of digital measuring devices. While it is true that there are modern alternatives available, a steel square still offers several advantages. It is durable, reliable, and does not require batteries or calibration. Furthermore, using a steel square can provide a tactile and hands-on experience that many find gratifying. To conclude, the misconceptions surrounding the use of a steel square include its limited application to right angles, its exclusive association with certain professions, the assumption of complexity, and the belief that it is outdated. However, by understanding the versatility, accessibility, and practicality of this tool, these misconceptions can be dispelled, encouraging more individuals to embrace its benefits in various applications.

- Q: Can a steel square be used for setting up a table saw?

- Indeed, the use of a steel square for the setup of a table saw is possible. A steel square, alternatively named a carpenter's square or framing square, exhibits versatility as a woodworking tool, serving numerous purposes. One such purpose entails the setup of a table saw. Its utility lies in guaranteeing the perpendicularity of the table saw blade relative to the table, a crucial aspect for precise and accurate cuts. By positioning the steel square against both the blade and the table, adjustments can be made to impeccably align the blade with the table surface. Moreover, the steel square can be employed to assess the alignment of the fence, ensuring it remains parallel to the blade in order to facilitate accurate rip cuts. Thus, the steel square proves to be an invaluable tool for the setup of a table saw while simultaneously optimizing its performance.

- Q: How do you hold a steel square properly?

- To achieve proper grip and control of a steel square, adhere to the following instructions: 1. Begin by firmly grasping the handle of the steel square with your dominant hand, ensuring that your fingers envelop the handle for a secure hold. 2. Place your thumb on the top section of the handle, allowing it to rest against the steel blade. This action will provide supplementary stability and control while clutching the square. 3. Position your non-dominant hand on the opposite end of the steel blade, near the corner. Utilize your thumb and fingers to securely hold the blade in place. 4. Verify that the steel square is parallel to your body, with the blade facing away from you. This particular orientation will enable precise measurements and markings. 5. When utilizing the steel square, exert firm pressure on the blade against the surface or material you are working on. This will aid in maintaining stability and prevent any movement that might compromise measurement accuracy. 6. Always ensure that your fingers remain clear of the blade's edge to prevent any potential accidents or injuries. Be mindful of the placement of your fingers as you proceed with your work. 7. Lastly, maintain a comfortable and well-balanced stance while clutching the steel square. This will enhance your control and accuracy when using it for measuring or marking purposes. By adhering to these guidelines, you can guarantee the correct handling of a steel square, enabling efficient and precise work in various woodworking, metalworking, or construction endeavors.

- Q: Can a steel square be used for checking the alignment of a planer bed?

- Certainly! A planer bed's alignment can be checked using a steel square. This versatile measuring tool guarantees the accuracy and alignment of different surfaces, including the planer bed. To verify if the planer bed is perpendicular or parallel to the reference point, simply position the steel square against it. If the planer bed is not properly aligned, adjustments can be made to ensure precise and accurate planing operations. However, it is worth mentioning that for extremely accurate alignment checks, more precise measurements and tools may be necessary, as a steel square only provides a general indication of alignment.

- Q: Can a steel square be used for measuring pipe fittings?

- Yes, a steel square can be used for measuring pipe fittings. The straight edges of a steel square can be used to ensure that the pipe fittings are at right angles to each other. Additionally, the 90-degree angle of the square can be used to verify the accuracy of the pipe fitting's angles and ensure that they are properly aligned. However, it is important to note that for precise measurements and to account for any variations in the thickness of the pipe or fitting, specialized measuring tools such as calipers or tape measures may be more appropriate.

Send your message to us

Steel Billet in Square Straight Form Big Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords