Stainless Steel NO.1 Finish Grade 304 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

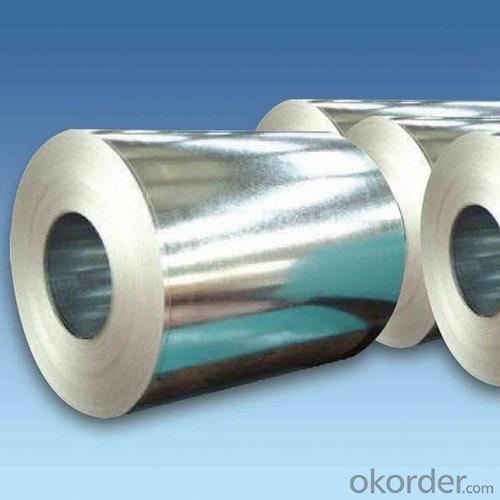

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheet

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Are stainless steel sheets suitable for electrical applications?

- Stainless steel sheets, indeed, prove to be a fitting choice for electrical applications. Their exceptional electrical conductivity and resistance to corrosion have made them highly favored for electrical components and equipment. They find extensive use in the fabrication of electrical enclosures, connectors, and terminals. Moreover, stainless steel sheets possess remarkable durability and longevity in electrical applications due to their ability to endure high temperatures and exhibit commendable mechanical properties.

- Q: How do you cut intricate designs in stainless steel sheets?

- One effective way to cut intricate designs in stainless steel sheets is by using a laser cutting machine. Laser cutting technology allows for precise and intricate cuts, making it ideal for complex designs. The laser beam melts, burns, or vaporizes the material, resulting in a clean and accurate cut without the need for additional finishing. This method ensures high-quality and precise cuts in stainless steel sheets.

- Q: Can stainless steel sheets be cut or shaped?

- Yes, stainless steel sheets can be cut or shaped using various methods such as shearing, laser cutting, plasma cutting, or forming processes like bending, rolling, or stamping.

- Q: Are stainless steel sheets suitable for food preparation surfaces?

- Stainless steel sheets are highly suitable for food preparation surfaces, making them a top pick for kitchen countertops, cutting boards, and other areas where food is prepared. The many advantageous properties of stainless steel contribute to its popularity. Firstly, it is non-porous, meaning it does not absorb smells, flavors, or bacteria. This characteristic ensures high levels of hygiene and easy cleaning, reducing the risk of cross-contamination. Additionally, stainless steel is resistant to corrosion, staining, and heat, making it a long-lasting and durable option. Its smooth surface is also perfect for rolling out dough or chopping ingredients. Moreover, stainless steel is non-reactive, so it does not interact with acidic or alkaline foods, preserving the taste and quality of the prepared dishes. All in all, stainless steel sheets are an exceptional choice for food preparation surfaces due to their cleanliness, durability, and food safety qualities.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are excellent for oil and gas equipment. Stainless steel is known for its exceptional resistance to corrosion, making it highly suitable for use in the oil and gas industry where exposure to harsh environments, chemicals, and high temperatures is common. Stainless steel sheets have superior strength and durability, ensuring they can withstand the demanding conditions in oil and gas equipment. Additionally, stainless steel sheets are easy to clean and maintain, which is crucial in industries that require strict hygiene standards. Their resistance to heat and pressure further enhances their suitability for oil and gas equipment. Overall, stainless steel sheets are a reliable and practical choice for the construction of oil and gas equipment, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Are stainless steel sheets scratch-resistant?

- Yes, stainless steel sheets are generally scratch-resistant. Stainless steel is known for its durability and resistance to scratches, making it an ideal material for various applications, including kitchen appliances, countertops, and decorative purposes. However, it is important to note that while stainless steel is highly resistant to scratches, it is not completely scratch-proof. Sharp objects or abrasive materials can still cause scratches or scuff marks on the surface of stainless steel sheets, especially with excessive force or repeated contact. Regular maintenance and proper care can help minimize the appearance of scratches and keep stainless steel sheets looking their best.

- Q: What is the maximum length of a stainless steel sheet?

- The maximum length of a stainless steel sheet can vary depending on the manufacturer and specific requirements, but it is generally available in standard sizes of up to 12 feet (3.6 meters) long. However, longer custom lengths may be available upon request.

- Q: What is the abrasion resistance of stainless steel sheets?

- The abrasion resistance of stainless steel sheets is generally considered to be high. Stainless steel is known for its durability and hardness, making it resistant to wear and tear caused by friction or contact with abrasive materials. The specific level of abrasion resistance can vary depending on the grade and finish of the stainless steel sheet, as well as the specific application it is being used for. However, in general, stainless steel sheets are known to have excellent resistance to scratches, scuffs, and other forms of abrasion, making them a popular choice for various industries where durability and longevity are important factors.

- Q: What are the different types of patterned finishes available for stainless steel sheets?

- There are several types of patterned finishes available for stainless steel sheets, including embossed, textured, perforated, brushed, and hammered finishes. Each of these finishes offers a unique aesthetic appeal and texture to the stainless steel, allowing for versatile applications in various industries such as architecture, interior design, and automotive.

- Q: Can stainless steel sheets be used for jewelry making?

- Indeed, jewelry making can make use of stainless steel sheets. The durability, tarnishing resistance, and hypoallergenic nature of stainless steel make it a favored material for crafting jewelry. Its versatility allows for easy cutting, shaping, and texturing, resulting in one-of-a-kind designs. A wide range of jewelry, such as earrings, rings, bracelets, pendants, and even intricate chains, can be made using stainless steel sheets. Moreover, stainless steel jewelry is often more cost-effective than precious metals like gold or silver, appealing to individuals on a budget or those seeking a contemporary and industrial look.

Send your message to us

Stainless Steel NO.1 Finish Grade 304 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords