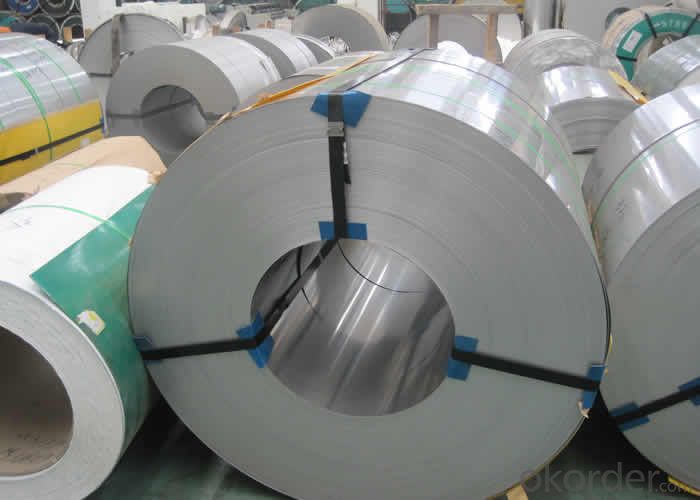

Stainless Steel Coil 201 Surface No.1 Hot Rolled Coil

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Hot Rolled Stainless Steel 201 half copper Chemical Composition(%) | |||||||

C | Si | Mn | P | S | Ni | Cr | Cu |

0.1 | 0.5 | 10 | 0.04 | 0.01 | 1.20/1.30 | 13.00/14.00 | 0.8/1.0 |

Grade: | 200 Series | Standard: | JIS,AISI,ASTM,GB,DIN | Thickness: | 2.5/3.0/4.0mm |

Width: | 485/510/550/610/1010/1240mm | Place of Origin: | Shanghai China (Mainland) | Brand Name: | CNBM |

Model Number: | 201 | Technique: | Hot Rolled | Application: | Industrial tubes/kitchen/bath |

Certification: | ISO | THK: | 2.5/3.0/4.0mm | Face: | No.1 |

Usage: | tubes/kitchen/bath | Origin: | CHINA | ||

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry. 201 hot rolled stainless steel coil, use to produce cold rolled stainless steel coil and stainless steel tube, pipe.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: Are stainless steel strips suitable for decorative trim?

- Yes, stainless steel strips are suitable for decorative trim. They are durable, resistant to corrosion, and have a sleek and modern appearance, making them a popular choice for adding a touch of elegance and sophistication to various surfaces and areas.

- Q: Where can stainless steel strips be purchased?

- There are multiple places where you can obtain stainless steel strips. One possibility is to go to local hardware stores or specialty metal suppliers that have a wide selection of stainless steel products. These establishments usually have various sizes and grades of stainless steel strips ready for purchase. Another option is to use online retailers and e-commerce websites, which offer a convenient way to buy stainless steel strips. Platforms like Amazon, eBay, or Alibaba have many sellers that provide stainless steel strips in different dimensions and quantities. However, it is crucial to make sure that the seller has a good reputation and provides accurate product descriptions to guarantee the quality and suitability of the stainless steel strips you are buying.

- Q: Are stainless steel strips magnetic?

- Yes, stainless steel strips can be magnetic or non-magnetic, depending on the specific type of stainless steel used. Stainless steel is an alloy that contains iron, which is inherently magnetic. However, the addition of certain elements such as nickel or manganese can alter the magnetic properties of stainless steel. Stainless steel strips that have a higher nickel content, such as the popular 304 or 316 grades, are generally non-magnetic. On the other hand, stainless steel strips with lower nickel content, such as the 400 series, can be magnetic. Therefore, it is important to consider the specific grade and composition of the stainless steel strip when determining its magnetic properties.

- Q: How do you determine the grade of a stainless steel strip?

- The grade of a stainless steel strip is determined by its chemical composition, which includes the percentages of various elements such as chromium, nickel, and carbon. Additionally, the properties of the stainless steel strip, such as its corrosion resistance, strength, and heat resistance, are considered when determining its grade. Various testing methods, including spectroscopy and mechanical tests, are used to analyze these factors and assign the appropriate grade to the stainless steel strip.

- Q: How do stainless steel strips compare to aluminum strips in terms of strength?

- Stainless steel strips are generally stronger than aluminum strips.

- Q: Are stainless steel strips resistant to embrittlement?

- Generally, stainless steel strips exhibit resistance to embrittlement. Embrittlement refers to the loss of ductility and the development of brittleness in a material, leading to cracking or fracturing when subjected to stress. Stainless steel, an alloy containing at least 10.5% chromium, forms a protective oxide layer on its surface. This oxide layer provides exceptional corrosion resistance and aids in preventing embrittlement. Moreover, stainless steel contains additional alloying elements like nickel and molybdenum, which further enhance its resistance to embrittlement. These elements contribute to maintaining the material's structure and integrity, even in extreme conditions or when exposed to high temperatures. However, it is important to acknowledge that certain factors can still induce embrittlement in stainless steel strips. For instance, exposure to excessively high temperatures (beyond the recommended operating range) or prolonged contact with specific chemicals can trigger embrittlement. Furthermore, improper heat treatment or welding procedures can also impact the material's resistance to embrittlement. Hence, while stainless steel strips generally possess resistance to embrittlement, it is imperative to consider the specific operating conditions and ensure appropriate handling, heat treatment, and maintenance to preserve the material's integrity.

- Q: Can stainless steel strips be plated or coated with another metal?

- Yes, stainless steel strips can be plated or coated with another metal. This process, known as electroplating or coating, involves applying a thin layer of a different metal onto the stainless steel surface. This is often done to improve the appearance, corrosion resistance, or other properties of the stainless steel strips.

- Q: Can stainless steel strips be bent or folded without cracking?

- Stainless steel strips possess the ability to be bent or folded without experiencing any cracking. The exceptional ductility and formability of stainless steel allow for effortless manipulation into diverse shapes without sustaining any fractures. However, it is crucial to consider the recommended bend radius, which pertains to the tightness of the bend, in order to prevent any potential damage or cracking to the material. Furthermore, the bendability of the stainless steel strip can also be influenced by its type and thickness, with thinner strips generally exhibiting greater flexibility. In summary, if appropriate techniques and parameters are adhered to, stainless steel strips can be subjected to bending or folding processes without encountering any cracking.

- Q: What are the typical tolerances for stainless steel strips?

- The tolerances for stainless steel strips differ based on the application requirements and manufacturing process employed. Typically, the industry adheres to standard tolerances ranging from +/- 0.005 to 0.010 inches for thickness and +/- 0.010 to 0.020 inches for width. These tolerances guarantee that the stainless steel strips meet dimensional requirements and are suitable for automotive, aerospace, and construction industries. Notably, more precise tolerances can be attained through specialized manufacturing techniques and the use of precision equipment.

- Q: Can stainless steel strips be stamped or engraved?

- Yes, stainless steel strips can be stamped or engraved. Stainless steel is a versatile material that can be easily stamped or engraved with various designs, logos, letters, or numbers. Stamping involves pressing the steel strip with a die to create a specific pattern or shape, while engraving involves removing material from the surface to create a design. Both methods can be used to add decorative or functional elements to stainless steel strips, making them suitable for a wide range of applications in industries such as automotive, aerospace, electronics, and jewelry.

Send your message to us

Stainless Steel Coil 201 Surface No.1 Hot Rolled Coil

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords