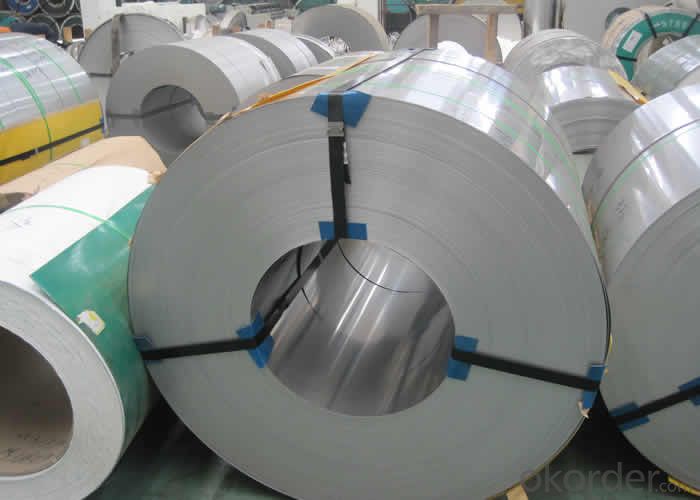

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK: 2.3/2.5/3.0/4.0mm

Width: 485/510/550/610/1010/1240mm

Face: No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%

Modulus Of Elasticity:29,000,000 Psi

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: What is the hardness of stainless steel strips?

- The hardness of stainless steel strips can differ based on various factors, including the specific grade of stainless steel, the applied heat treatment, and the method of manufacturing. Stainless steel is generally recognized for its hardness and strength, but different grades offer varying levels of hardness. Stainless steel strips are commonly produced in grades like 304, 316, 430, and 201, among others. These grades possess different compositions and properties that directly impact their hardness. Typically, stainless steel strips are hardened through cold rolling, a process that involves compressing and stretching the material to enhance its hardness and strength. To measure the hardness of stainless steel strips, the Rockwell scale is commonly used. This scale offers a standardized method for determining the material's resistance to indentation. The typical hardness values for stainless steel strips can range from approximately 70 HRB (Rockwell B scale) for softer grades to over 90 HRB for harder grades. It's worth noting that the hardness of stainless steel strips can also be further adjusted through additional heat treatment processes, such as annealing or tempering. These processes can either increase or decrease the material's hardness, depending on the desired characteristics and application requirements. In conclusion, the hardness of stainless steel strips can vary significantly depending on the specific grade, heat treatment, and manufacturing process. To determine the exact hardness for a particular application, it's essential to consult the material's technical specifications or seek advice from a metallurgical expert.

- Q: Can stainless steel strips be used in musical instruments?

- Yes, stainless steel strips can be used in musical instruments. Stainless steel is a versatile and durable material that is commonly used in various industries, including music. It offers excellent corrosion resistance, high strength, and good mechanical properties, making it suitable for different applications in musical instruments. Stainless steel strips can be used in instruments like guitars, pianos, drums, and other percussion instruments. For example, stainless steel strips can be used as frets on a guitar, providing a smooth surface for the strings to make contact and produce clear and crisp sounds. Stainless steel strips can also be used as keys or hammers in pianos, providing a consistent and reliable striking surface for the strings. In addition, stainless steel strips can be used in the construction of wind instruments. For instance, stainless steel strips can be used as reeds or valves in brass instruments like trumpets or saxophones. Stainless steel's corrosion resistance ensures longevity and prevents deterioration from moisture and saliva that these instruments are exposed to during play. Overall, stainless steel strips offer various benefits for musical instrument applications. They provide durability, corrosion resistance, and versatility, ensuring the instruments perform well and maintain their quality over time.

- Q: How do you prevent corrosion fatigue of stainless steel strips?

- To prevent corrosion fatigue of stainless steel strips, there are several steps that can be taken: 1. Opt for appropriate material: Select a stainless steel grade that possesses resistance to corrosion and fatigue. Commonly used grades like 316 and 304L exhibit excellent corrosion resistance properties. 2. Apply surface treatment: Enhance the corrosion resistance and prevent fatigue crack initiation by applying a protective coating or passivation treatment to the stainless steel strips. 3. Maintain cleanliness and perform regular upkeep: Ensure the stainless steel strips remain clean and devoid of substances that can expedite corrosion. Regularly inspect the strips for any signs of corrosion or fatigue and address them promptly. 4. Avoid harsh environments: Limit exposure of the stainless steel strips to corrosive environments like saltwater, acidic solutions, or high humidity conditions. If exposure is necessary, consider additional protective measures such as applying a barrier coating or implementing cathodic protection. 5. Handle and store properly: Handle the stainless steel strips with care to prevent any damage that could result in corrosion or fatigue cracks. Store them in a dry and controlled environment to prevent exposure to moisture or other corrosive agents. 6. Consider design factors: Ensure that the design of the stainless steel strips takes into account factors such as stress concentration, surface finish, and proper installation techniques. These considerations can help minimize the risk of fatigue and corrosion. 7. Regularly inspect and test: Implement a regular inspection and testing program to detect any early signs of corrosion fatigue. This can include visual inspections, non-destructive testing methods, and monitoring of environmental conditions. By implementing these preventive measures, the risk of corrosion fatigue in stainless steel strips can be significantly reduced, ensuring their long-term durability and performance.

- Q: Are stainless steel strips non-magnetic?

- Stainless steel strips are typically not magnetic, although the magnetic characteristics of stainless steel can differ depending on the specific alloy and composition. The commonly used stainless steel types, like 304 and 316, do not possess magnetic properties when in their annealed condition, meaning they do not attract or retain a magnetic charge. This quality makes them suitable for various applications where magnetism is unwanted. However, certain stainless steel alloys, such as ferritic grades, may display magnetic properties due to their higher iron content. Therefore, it is essential to take into account the specific type of stainless steel when assessing its magnetic attributes.

- Q: Can 111 stainless steel strips be used in the chemical processing industry?

- In the chemical processing industry, it is possible to utilize 111 stainless steel strips. These stainless steel strips belong to the 300 series, which is renowned for its exceptional resistance to corrosion. Consequently, they are well-suited for environments with high chemical levels and corrosive substances. Moreover, 111 stainless steel strips possess commendable strength, toughness, and formability, rendering them suitable for a variety of applications in the chemical processing industry, including tanks, pipes, valves, and other equipment. Nevertheless, it is crucial to consider the particular requirements and conditions of a given chemical processing operation to ensure that 111 stainless steel is both compatible and appropriate for the specific application.

- Q: How do stainless steel strips compare to other materials?

- Stainless steel strips have several advantages that make them stand out when compared to other materials. Firstly, stainless steel is known for its exceptional corrosion resistance. This makes it ideal for various applications where the material will be exposed to moisture, chemicals, or harsh environments. Unlike other materials, stainless steel does not rust or stain easily, ensuring durability and longevity. Secondly, stainless steel strips offer excellent strength and toughness. They have a high tensile strength, which means they can withstand heavy loads and resist deformation under stress. This makes stainless steel strips suitable for applications that require structural integrity and reliability. Another significant advantage of stainless steel strips is their aesthetic appeal. Stainless steel has a sleek and modern appearance that can enhance the visual appeal of any project or product. It is often used in architecture and interior design for its clean and contemporary look. Furthermore, stainless steel strips are highly versatile. They can be easily formed, welded, and fabricated into various shapes and sizes to meet specific requirements. This flexibility allows stainless steel strips to be used in a wide range of industries, including construction, automotive, aerospace, and manufacturing. Lastly, stainless steel is a sustainable and environmentally friendly material. It is 100% recyclable, making it an excellent choice for projects with a focus on sustainability. Additionally, stainless steel has a long lifespan, reducing the need for frequent replacements and minimizing waste. Overall, stainless steel strips offer superior corrosion resistance, strength, aesthetic appeal, versatility, and sustainability when compared to other materials. These characteristics make stainless steel an excellent choice for numerous applications in various industries.

- Q: Can stainless steel strips be used in food storage containers?

- Indeed, food storage containers can utilize stainless steel strips. Stainless steel emerges as a favored material selection for these containers due to its numerous advantageous qualities. Notably, it exhibits non-reactivity, implying that it does not engage with or modify the taste, appearance, or aroma of the stored food. Moreover, stainless steel boasts corrosion resistance, endowing it with durability and longevity. On top of that, it proves effortless to clean and maintain, while effectively avoiding the retention of unpleasant odors or unsightly stains. These exceptional attributes render stainless steel strips an optimal alternative for food storage containers, guaranteeing the preservation of freshness, safety, and the prevention of contamination.

- Q: Can stainless steel strips be recycled?

- Indeed, it is possible to recycle stainless steel strips. This material is exceptionally recyclable due to its ability to maintain its qualities and durability even after being melted and reprocessed. The recycling procedure encompasses gathering the stainless steel strips, categorizing them based on their composition and thickness, and subsequently melting them in a furnace to eliminate any impurities. Once the impurities are eradicated, the molten stainless steel is solidified and converted into fresh stainless steel products or components. By recycling stainless steel, not only are valuable natural resources preserved, but the energy and emissions required for manufacturing new stainless steel from raw materials are also reduced, making it a choice that is kind to the environment.

- Q: What are the common industry standards for stainless steel strips?

- The common industry standards for stainless steel strips vary depending on the specific application and requirements. However, there are several widely recognized standards that are commonly followed by manufacturers and users in the stainless steel industry. One of the most commonly referenced standards is the American Society for Testing and Materials (ASTM) standard. ASTM A666/A666M provides the standard specification for annealed or cold-worked austenitic stainless steel strips, which includes the chemical composition, mechanical properties, and dimensional tolerances for these materials. Additionally, the International Organization for Standardization (ISO) has several standards related to stainless steel strips. ISO 9445 specifies the tolerances on dimensions and form for continuously cold-rolled stainless steel narrow strip, while ISO 9444 provides general requirements for the preparation of steel substrates before application of paints and related products. In Europe, the European Committee for Standardization (CEN) has developed the EN standards for stainless steel strips. EN 10151 specifies the technical delivery conditions for cold-rolled stainless steel strip for springs, while EN 10088-2 covers the technical delivery conditions for stainless steel strip for general purposes. Apart from these widely recognized standards, there may be specific industry or application-based standards that are followed in certain sectors. These standards may outline additional requirements or specifications depending on the intended use of the stainless steel strips, such as in automotive, construction, or medical industries. It is important for manufacturers and users to be aware of the relevant industry standards and ensure compliance with these standards to ensure the quality, performance, and compatibility of stainless steel strips in their specific applications.

- Q: Can stainless steel strips be used in cryogenic applications?

- Indeed, cryogenic applications can employ stainless steel strips. Renowned for its exceptional ability to withstand extreme temperatures, stainless steel is especially adept at enduring the frigid conditions encountered in cryogenic environments. Even when subjected to exceedingly low temperatures, it maintains its robustness and structural integrity, rendering it well-suited for deployment in cryogenic applications. Moreover, stainless steel boasts commendable resistance to corrosion, a crucial attribute in cryogenic settings where the presence of moisture and other corrosive entities is not uncommon. All in all, stainless steel strips prove themselves to be an unwavering and long-lasting option for utilization in cryogenic applications.

Send your message to us

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords