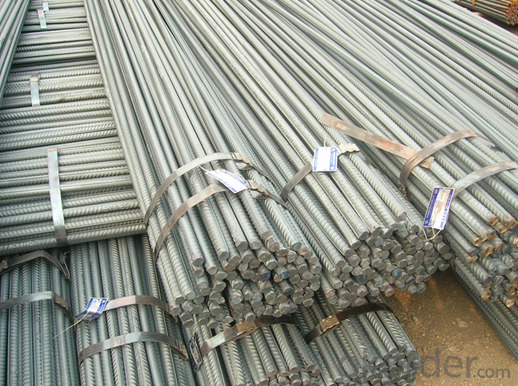

Stainless Steel Bar/Stainless Steel Rod/Deformed Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Markets:

Mid East

Western Europe

Eastern Europe

North America

South America

Southeast Asia

Eastern Asia

Oceania

Africa

Our Services

Our Goal:supply quality products with the best services and satisfy the

requirements of clients from at home and abroad;

Management philosophy:Pursue the best quality, the best price, the best service

and the best credit standing

Corporation culture:Innovation is an eternal motif; surpass excellence is our

unremitting pursuit.

Product Description

Item | stainless steel bar,stainless steel rod | |

Standard | ASTMA276,A479,A582,GB4226-84,GB/T1220-2007,JISG4311-91,JISG4318-98, EN 10095-99,GB4226-84,EN10088-3-2005,JISG4303-2005,etc | |

Diameter | 3~800mm | |

Length | 5.8m,6m,7m,8m,or as required. | |

Surface | Black,peeled,Polished,bright,hair line,brush,sand blast,etc | |

Package | Standard export package,suit for all kinds of transport, or as required | |

Price term | Ex-Work,FOB,CNF,CFR,CIF,FCA,DDP,DDU,etc | |

Payment term | TT,L/C,Western Union | |

MOQ | 500Kg | |

Export to | Ireland,Singapore,Indonesia,Ukraine,SaudiArabia,Spain,Canada,USA,Brazil,Thailand,Russia, Korea,Iran,India,Egypt,Oman,Malaysia,Viet Nam,Dubai,Turkey,Mexico,Peru,Italy,etc | |

Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC:12032mm(Lengh)x2352mm(Width)x2698mm(High) | |

Application | Stainless steel bar applies to petroleum,chemical industry,electric power,boiler,high temperature resistant,low temperature resistant,corrosion resistant seamless steel pipe used.Stainless steel bar can be made according to the customers requirements. | |

Contact | If you have any question,please feel free to contact me . We are sure your inquiry or requirements will get prompt attention. | |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q: If needed for Defence could a stainless steel sword kill someone my buddy wanted this sword for Defece after it is sharpend here is a picture

- Stainless steel only works for knives, anything past 12 inches it starts getting brittle, carbon steel is what you are looking for. As far as home defense, if you don't know how to use it, you will be worse off.

- Q: How do steel coils contribute to the HVAC industry?

- Steel coils are an integral component of the HVAC (Heating, Ventilation, and Air Conditioning) industry and play a crucial role in the functioning and efficiency of HVAC systems. These coils are typically made from high-quality steel, such as stainless steel or galvanized steel, which ensures durability and resistance to corrosion. One of the main ways steel coils contribute to the HVAC industry is by facilitating heat transfer. HVAC systems use coils to transfer heat between the air and a refrigerant. In air conditioning units, for example, the evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the outside air. The steel coils in these units provide a large surface area for efficient heat exchange, enabling the cooling or heating of the air as required. Moreover, steel coils also contribute to the overall energy efficiency of HVAC systems. By maximizing heat transfer, these coils allow HVAC systems to operate at optimal performance levels while consuming less energy. This not only helps reduce energy costs for users but also makes HVAC systems more environmentally friendly by minimizing energy consumption and greenhouse gas emissions. Steel coils in HVAC systems also contribute to the quality of indoor air. As air passes over the coils, any impurities, such as dust, dirt, or mold, can accumulate on the coil's surface. Regular maintenance and cleaning of the coils are essential to prevent the buildup of contaminants that could negatively impact air quality. Properly maintained steel coils ensure clean and healthy indoor air, which is particularly important for commercial buildings, hospitals, and other spaces where air quality is crucial. In addition to their heat transfer and energy efficiency capabilities, steel coils also provide durability and longevity to HVAC systems. Steel is a strong and resilient material that can withstand high temperatures, pressure, and environmental stressors. By using steel coils, HVAC systems can operate reliably and efficiently for extended periods, reducing the need for frequent repairs or replacements. Overall, steel coils are a vital component of the HVAC industry. They enable efficient heat transfer, improve energy efficiency, enhance indoor air quality, and provide durability to HVAC systems. Without steel coils, the performance and effectiveness of HVAC systems would be significantly compromised, making them an indispensable element of the HVAC industry.

- Q: what does steel have inside of it that makes it rust.I need the answer fast!!!!!!!!!

- Steel is made adding carbon to iron.The iron in steel reacts with oxygen in the air, producing ferric oxide(Rust).

- Q: My boyfriend says he has balls of steel.

- yes, he had to sew special underwear for himself so he can support his steel balls; like a bra for down there.

- Q: How are steel coils used in the manufacturing of industrial pumps?

- Steel coils are used in the manufacturing of industrial pumps as they are typically used to construct the pump housing and impellers, providing the necessary strength and durability for handling high-pressure fluids and withstanding harsh operating conditions. The steel coils are processed and shaped into various components, ensuring the structural integrity and reliability of the pump, ultimately contributing to its efficient operation and long lifespan.

- Q: What are the different types of steel coil edge conditions?

- The different types of steel coil edge conditions include mill edge, slit edge, and deburred edge.

- Q: How are steel coils used in the production of metal roofing panels?

- Steel coils are used in the production of metal roofing panels by being unrolled and fed through a rolling machine that shapes and forms the metal into the desired panel shape. This allows for efficient and precise manufacturing of metal roofing panels, which are then used for construction purposes.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they are the primary material for constructing the door's core. The steel coils are shaped and layered to create a strong and heat-resistant core, which provides the necessary structural integrity and fire resistance required for fireproof doors.

- Q: I've played guitar for years, now I want a steel guitar. As a beginner, to learn and experiment with, which one would be better for me?

- Pedal steel is very difficult. You need to co-ordinate both hands, both feet and both knees to play it effectively. Lap steel is a lot easier. I suppose it depends how much of a challenge you want. A good lap steel guitar is usually cheaper than a good pedal steel too, so that's another consideration to take into account.

Send your message to us

Stainless Steel Bar/Stainless Steel Rod/Deformed Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords