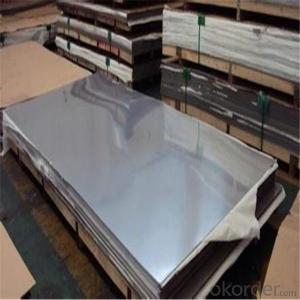

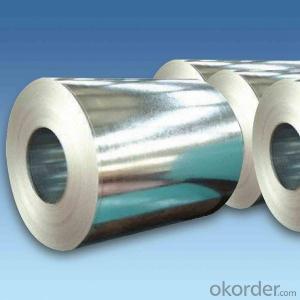

Stainless Plates NO.2B Cold Rolled From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

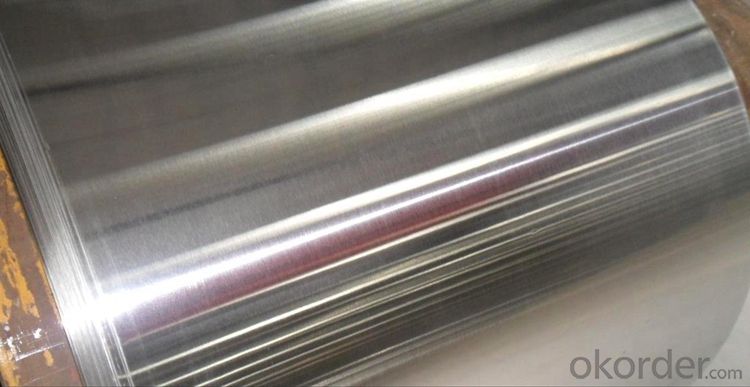

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Are stainless steel sheets suitable for architectural wire mesh?

- Architectural wire mesh benefits greatly from the use of stainless steel sheets. This material is a popular choice in architectural applications because of its many advantageous properties. Firstly, stainless steel is exceptionally durable and resistant to corrosion, making it perfect for both indoor and outdoor use over long periods of time. This corrosion resistance is particularly important for architectural wire mesh, as it ensures the material will maintain its integrity and appearance over time. In addition to this, stainless steel sheets offer excellent strength and stability, making them capable of withstanding the various stresses and strains that architectural wire mesh may encounter. This is crucial in applications where the mesh needs to support structural loads or provide security. Furthermore, stainless steel comes in different grades, allowing for customization to meet specific project requirements in terms of strength and flexibility. Stainless steel sheets also have a significant aesthetic appeal. Their sleek and modern appearance complements contemporary architectural designs and adds an elegant touch to any space. Moreover, stainless steel can be finished in different ways, such as brushed, polished, or coated, to achieve the desired visual effect. Lastly, stainless steel is a sustainable choice for architectural wire mesh. It is 100% recyclable, reducing environmental impact and supporting green building initiatives. Additionally, its long lifespan and low maintenance requirements contribute to its sustainability, minimizing the need for frequent replacements or repairs. In conclusion, stainless steel sheets are highly suitable for architectural wire mesh due to their durability, corrosion resistance, strength, aesthetic appeal, and sustainability. Architects and designers prefer them for their versatility in meeting various project requirements and their ability to create visually stunning and functional wire mesh installations.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are suitable for medical equipment or devices. They possess excellent corrosion resistance, durability, and high strength, making them ideal for use in medical settings. Stainless steel is also easy to clean and maintain, which is crucial for maintaining a sterile environment.

- Q: Are stainless steel sheets suitable for automotive grilles or trim?

- Yes, stainless steel sheets are suitable for automotive grilles or trim due to their durability, corrosion resistance, and ability to withstand harsh weather conditions.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: What are the benefits of using embossed stainless steel sheets?

- Using embossed stainless steel sheets has several advantages. Firstly, these sheets offer a heightened aesthetic appeal. The unique textures and visual interest created by the embossed patterns on the surface can transform any space, giving it a more modern and visually appealing look. This is applicable to both residential and commercial settings. In addition, embossed stainless steel sheets provide enhanced durability and strength. Stainless steel is already known for its resistance to corrosion, staining, and wear. The embossing process further reinforces the sheets, making them suitable for high traffic areas or places where damage or impact may occur. Moreover, embossed stainless steel sheets are incredibly versatile. They can be used in various applications, such as wall cladding, elevator panels, kitchen backsplashes, furniture, and architectural features. These sheets are easy to cut and shape, allowing for flexibility in design requirements. Furthermore, maintaining embossed stainless steel sheets is hassle-free. The smooth surface of the embossed patterns makes it easy to clean away dirt, grime, and fingerprints, ensuring a hygienic and spotless surface. This is particularly beneficial in areas that require high cleanliness standards, like kitchens or healthcare facilities. Lastly, embossed stainless steel sheets are environmentally friendly. Stainless steel is a highly sustainable material as it is 100% recyclable. The embossing process itself does not generate any waste or harmful byproducts, making these sheets an eco-friendly choice for those who want to reduce their carbon footprint and contribute to a greener environment. In conclusion, the advantages of using embossed stainless steel sheets include enhanced aesthetic appeal, increased durability and strength, versatility in applications, easy maintenance, and eco-friendliness. These sheets are an excellent option for individuals seeking a durable, stylish, and sustainable material for their projects.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of punched finishes, each with distinct qualities and advantages. Let's explore some of the most commonly used options: 1. Round Hole: This punched finish, which features evenly spaced round holes, is highly versatile and widely utilized. It enables effective airflow and visibility and finds applications in ventilation systems, decorative panels, and filters. 2. Square Hole: With a clean and contemporary appearance, the square hole punched finish is often chosen when a more geometric pattern is desired. It is commonly employed in architectural projects, screens, and fencing. 3. Slotted Hole: The slotted hole punched finish is characterized by elongated holes, providing larger openings for enhanced visibility or improved drainage. It finds uses in grilles, sunshades, and safety barriers. 4. Hexagonal Hole: Offering an aesthetically pleasing pattern, the hexagonal hole punched finish showcases hexagon-shaped holes. It is commonly used in decorative applications like wall cladding, signage, and artistic installations. 5. Decorative Patterns: In addition to the standard punched finishes, stainless steel sheets can be customized with various decorative patterns, including personalized designs, logos, or intricate shapes. This allows for a unique and personalized touch in any project. When choosing a punched finish for stainless steel sheets, it is crucial to consider the specific requirements of the application, including aesthetics, functionality, and performance. Key factors to consider include hole size, open area percentage, strength, and corrosion resistance.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Elevator wall panels can indeed be constructed using stainless steel sheets. The utilization of stainless steel as a material for elevator interiors is highly favored due to its robustness, cleanliness, and aesthetic attractiveness. It imparts a sleek and contemporary appearance that enhances the overall look of the elevator. Furthermore, stainless steel is resistant to corrosion, staining, and scratching, rendering it suitable for high-traffic areas such as elevators. Moreover, it is effortless to clean and maintain, guaranteeing that the elevator walls remain in optimal condition for an extended period. What's more, stainless steel sheets can be tailored to meet specific design requirements and preferences, offering a plethora of finishes, patterns, and colors that can harmonize with the building or elevator's design. Ultimately, stainless steel sheets prove to be a superb option for elevator wall panels.

- Q: What does 8K stainless steel mean?

- 8K mirror surface definition: stainless steel surface after grinding and polishing, the surface is bright as a mirror, the photo reflects the person, commonly known as mirror 8K, it has corrosion resistance; and the mirror plate is the processing of follow-up color or etching board substrate. Mainly used in all kinds of decoration or metal optical products.

- Q: Can stainless steel sheets be used for jewelry making?

- Yes, stainless steel sheets can be used for jewelry making. Stainless steel is a durable and hypoallergenic material that is often used in the production of jewelry. It offers a sleek and modern look and can be easily shaped and manipulated into various designs and forms for making earrings, necklaces, bracelets, and other jewelry pieces.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Yes, stainless steel sheets are suitable for chemical reactors. Stainless steel is a preferred material in the chemical industry because of its excellent corrosion resistance properties. It can withstand a wide range of chemicals, including acids, alkalis, and solvents, without undergoing significant degradation or reacting with the substances being processed. Stainless steel sheets are particularly chosen for chemical reactors due to their high strength, durability, and resistance to high temperatures and pressure. They can handle the harsh conditions and aggressive substances found in chemical processes without compromising their structural integrity. Moreover, stainless steel sheets are easy to clean and maintain, making them suitable for applications where cleanliness is crucial, such as pharmaceutical and food processing industries. They also have excellent heat transfer properties, allowing for efficient temperature control within the reactor. In summary, stainless steel sheets are a reliable choice for chemical reactors due to their corrosion resistance, strength, durability, and thermal properties. They provide a safe and long-lasting solution for handling various chemicals, making them widely used in the chemical industry.

Send your message to us

Stainless Plates NO.2B Cold Rolled From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords