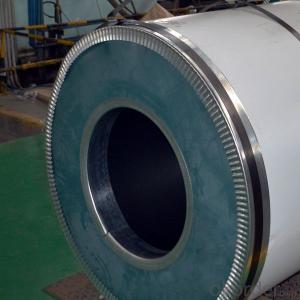

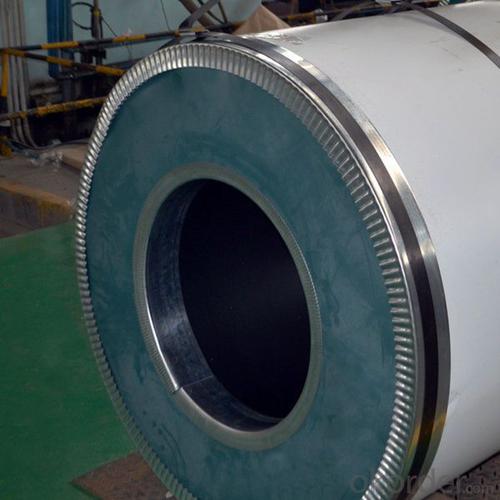

Stainless Good No.1 Finish Quality Steel Coils NO.1 Finish Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Type | Stainless Steel Coil /Cold rolled Steel Coils |

Thinckness | 0.23mm-0.8mm |

Diameter | 115mm-560mm |

Quantity | as customer's requirement |

Finish | 2B,BA,HL,MIRROR,NO.1-NO.4,8K,and so on. |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Material | 201,202, 301,304,410,430,409 |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | 7-15 days |

Quality | Primary |

Productivity | 3000-4000 tons/month |

Note | We can produce other standard as the customers’ requirement |

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Are stainless steel sheets suitable for automotive exhaust systems?

- Yes, stainless steel sheets are suitable for automotive exhaust systems. Stainless steel is known for its high temperature resistance, corrosion resistance, and durability, making it an ideal material for exhaust systems that are subjected to extreme heat and corrosive gases. Additionally, stainless steel sheets can be easily formed and welded, allowing for flexibility in designing exhaust systems for various vehicles.

- Q: Can stainless steel sheets be used for insulation?

- No, stainless steel sheets cannot be used for insulation. Stainless steel is a good conductor of heat and electricity, so it would not provide adequate insulation.

- Q: What type of stainless steel plate made by imported vibrating disk?

- Compared with similar products, the vibration disc produced by our factory is of high precision, low noise, long life and easy operation. It solves the problem of automatic sorting and feeding.

- Q: Can stainless steel sheets be used in medical applications?

- Yes, stainless steel sheets can be used in medical applications. Stainless steel is commonly used in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is often used for surgical instruments, medical equipment, implants, and other medical devices.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets come in various standard sizes and thicknesses that are widely used in different industries and applications. The standard sizes typically range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be obtained based on specific requirements. Regarding thicknesses, stainless steel sheets are available in several standard options, including 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). These thicknesses refer to the nominal thickness, and actual thickness may vary slightly. It is important to note that stainless steel sheets can also be obtained in metric sizes, with common thicknesses ranging from 0.5 mm to 3 mm. This allows for flexibility and compatibility with international standards and specifications. Overall, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements, ensuring wide availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: How do you install stainless steel sheets?

- To install stainless steel sheets, you will need a few basic tools and follow these steps: 1. Measure and prepare: Start by measuring the area where you want to install the stainless steel sheets. Ensure that the surface is clean, dry, and free from any dust or debris. If needed, sand down any rough spots or imperfections on the surface. 2. Cut the sheets: Using a metal cutting tool like a circular saw or a jigsaw with a metal cutting blade, cut the stainless steel sheets to the desired size and shape. Make sure to wear safety goggles and gloves while cutting to protect yourself. 3. Apply adhesive: Apply a high-strength construction adhesive to the backside of the stainless steel sheet. Make sure to apply the adhesive evenly, leaving no gaps or air pockets. You can also use a notched trowel to spread the adhesive for better coverage. 4. Position and secure: Carefully place the stainless steel sheet onto the prepared surface, making sure to align it properly. Apply gentle and even pressure to ensure the sheet adheres to the surface. You can use a roller or a clean cloth to press the sheet firmly onto the surface. 5. Secure with screws: If necessary, use stainless steel screws to secure the sheet further. Place the screws along the edges and corners, ensuring they are evenly spaced. Make sure not to overtighten the screws to avoid damaging the sheet. 6. Trim and finish: If any excess stainless steel sheet is hanging over the edges, use a metal cutting tool to trim it down to the desired size. Once trimmed, smooth out any rough edges using a file or sandpaper. You can also use a stainless steel cleaner to remove any smudges or fingerprints and give it a polished finish. Remember to always follow the manufacturer's instructions for the specific stainless steel sheets you are using, as installation methods may vary slightly. Additionally, it is recommended to seek professional assistance if you are unsure or not comfortable with the installation process.

- Q: Can stainless steel sheets be used for elevator frames?

- Indeed, elevator frames can be constructed using stainless steel sheets. Renowned for its durability, strength, and resistance to corrosion, stainless steel proves itself as an excellent choice for numerous purposes, including elevator frames. By employing stainless steel sheets, elevator frames acquire a lasting and visually appealing structure that withstands the rigors of daily usage. Moreover, stainless steel's sleek and contemporary appearance elevates the overall elevator design, imparting a refined and fashionable allure.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets can vary depending on their thickness and dimensions. Generally, stainless steel sheets weigh between 1.5 to 3 pounds per square foot.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are suitable for aerospace applications. Stainless steel is a versatile and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and high-temperature resistance, making it ideal for use in the aerospace industry. It is commonly used in the construction of aircraft structures, engine components, and fuel systems due to its ability to withstand extreme conditions and maintain structural integrity. Stainless steel sheets are also easy to form, weld, and fabricate, allowing for customization and precise engineering in aerospace applications. Additionally, stainless steel's resistance to fatigue and erosion makes it a reliable choice for aerospace components that are subject to constant stress and harsh environments. Overall, stainless steel sheets provide the necessary characteristics to meet the demanding requirements of the aerospace industry, making them a suitable choice for various applications.

- Q: What's the difference between galvanized steel and stainless steel?

- Galvanized steel strip products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commercial industries. The construction industry is mainly used in the manufacture of anti-corrosive industrial and civil building roof panel and roof grate; for the manufacture of electrical appliance shell, light industry, civil chimney, kitchen appliances, automobile industry is mainly used in the manufacture of anti-corrosive parts of car; animal husbandry and fishery is mainly used as freezing processing tools for grain storage, meat and aquatic products the main business; used as a material storage, packaging etc..

Send your message to us

Stainless Good No.1 Finish Quality Steel Coils NO.1 Finish Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords