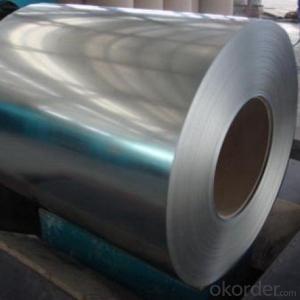

Hot Rolled Stainless Steel Coils NO.1 Finish Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: What is the weight of a stainless steel sheet?

- The weight of a stainless steel sheet depends on its dimensions (length, width, and thickness).

- Q: How do I prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, it is important to keep them clean and dry. Avoid exposure to harsh chemicals or high chloride environments, as they can cause corrosion. Regularly inspect the sheets for any signs of damage or pitting, and promptly address any issues. Applying a protective coating or using stainless steel cleaners can also help to prevent pitting and maintain the appearance and integrity of the sheets.

- Q: Can stainless steel sheets be used in medical applications?

- Yes, stainless steel sheets can be used in medical applications. Stainless steel is a popular choice in the medical field due to its excellent corrosion resistance, durability, and ease of sterilization. It is widely used in medical devices, surgical instruments, and implantable components due to its ability to withstand harsh sterilization processes such as autoclaving, which is crucial for maintaining cleanliness and preventing infections. Additionally, stainless steel is biocompatible, meaning it does not react with the body's tissues and does not cause any harm or adverse reactions. Overall, stainless steel sheets are a reliable and versatile material for various medical applications.

- Q: Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

- Q: What are the different types of corrosion that stainless steel sheets can resist?

- Stainless steel sheets are highly resistant to various types of corrosion, including general corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking.

- Q: How do you calculate the weight of a stainless steel sheet?

- To calculate the weight of a stainless steel sheet, you need to know its dimensions (length, width, and thickness) and the density of stainless steel. Multiply the area of the sheet (length x width) by the thickness and then multiply that by the density to obtain the weight.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Yes, stainless steel sheets can be used for kitchen countertops. Stainless steel is a popular choice for kitchen countertops due to its durability, heat resistance, and hygienic properties. It is resistant to stains, corrosion, and rust, making it a suitable material for a high-traffic area like the kitchen. Stainless steel countertops are also easy to clean and maintain, making them a practical option for busy kitchens. Additionally, stainless steel adds a sleek and modern look to the kitchen, making it a popular choice for contemporary and industrial-style kitchens.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- Using stainless steel sheets in the medical industry offers several benefits: 1. Maintaining Hygiene and Cleanliness: Stainless steel's non-porous nature makes it easy to clean and disinfect, making it an excellent option for medical equipment, surgical instruments, and hospital furniture. It resists bacteria, mold, and other pathogens, ensuring a hygienic environment. 2. Ensuring Longevity and Durability: Stainless steel can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This durability extends the lifespan of medical equipment and instruments, reducing the need for frequent replacements. 3. Providing Strength and Safety: Stainless steel sheets offer exceptional strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment are constantly utilized and handled. 4. Resisting Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Enhancing Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that contributes to the overall aesthetic appeal of medical equipment and instruments. This creates a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Promoting Recyclability: Stainless steel is a sustainable material that can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, stainless steel sheets offer advantages such as hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Yes, stainless steel sheets can be used for elevator wall panels. Stainless steel is a popular choice for elevator interiors due to its durability, cleanliness, and aesthetic appeal. It offers a sleek and modern look that can enhance the overall appearance of the elevator. Moreover, stainless steel is resistant to corrosion, stains, and scratches, making it suitable for high-traffic areas like elevators. It is also easy to clean and maintain, ensuring that the elevator walls remain in good condition for a long time. Additionally, stainless steel sheets can be customized in various finishes, patterns, and colors to match the design requirements and preferences of the building or elevator. Overall, stainless steel sheets are an excellent choice for elevator wall panels.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- 1. cold-rolled steel plate due to a certain degree of hardening, low toughness, the price is more expensive;2. surface anaerobic cold rolling scale, good quality;3. cold deformation products, high dimensional accuracy, good surface quality;4. cold rolling because of its production process in all walks of life in a wide range of applications, such as various types of cold stamping parts, cold rolled cold extrusion profiles, cold coil spring, cold drawn wire, cold heading bolts.Hot rolling (hot rolling): relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.

Send your message to us

Hot Rolled Stainless Steel Coils NO.1 Finish Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords