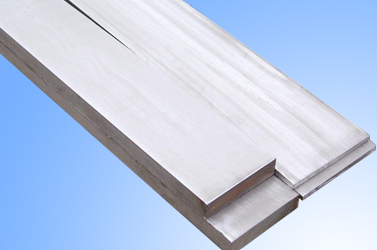

SS400 Q235B hot rolled steel flat bar Slitting flat bar galvanized flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

steel flat bar

steel flat bar thick : 2-20mm

steel flat bar wide : 10-870mm

steel flat bar length : 6m;9m;12m

Hot Rolled Flat Bar/ Slitting Flat Bar

1.We produce all the specifications of hot rolled flat steel and slitting flat bar

2.Lgare quantity in stock.

3.Best service.

flat bar

1.size: 20--150mm *2--20mm a36 flat bar

2.material:Q235 SS400 a36 flat bar

3.width:20-150mm

4.thickness:2--20mm

5.flat steel

1) Size: 2# - 150#

2) steel grade:Q195-Q235, ss400, s235 s275 s355 st37 st52.....

Packing:Suitable for export with hooks for easy unloading of material with bundle weightabout 2MT

Size | Width | Tolerance | Thickness | Tolerance |

20 | 20 | +0.5 -1 | 2--4 | +0.3 -0.5 |

22 | 22 | +0.5 -1 | 2--4 | +0.3 -0.5 |

25 | 25 | +0.5 -1 | 2--6 | +0.3 -0.5 |

28 | 28 | +0.5 -1 | 2--6 | +0.3 -0.5 |

30 | 30 | +0.5 -1 | 2--6 | +0.3 -0.5 |

32 | 32 | +0.5 -1 | 2--6 | +0.3 -0.5 |

35 | 35 | +0.5 -1 | 2--6 | +0.3 -0.5 |

40 | 40 | +0.5 -1 | 36 | +0.3 -0.5 |

45 | 45 | +0.5 -1 | 36 | +0.3 -0.5 |

50 | 50 | +0.5 -1 | 36 | +0.3 -0.5 |

55 | 55 | +0.6 -1.3 | 3--6 | +0.3 -0.5 |

60 | 60 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

65 | 65 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

70 | 70 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

75 | 75 | +0.6 -1.3 | 3--10 | +0.3 -0.5 |

80 | 80 | +0.9 -1.8 | 3--10 | +0.3 -0.5 |

85 | 85 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

90 | 90 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

95 | 95 | +0.9 -1.8 | 6--10 | +0.3 -0.5 |

100 | 100 | +0.9 -1.8 | 6--12 | +0.3 -0.5 |

105 | 105 | +1 -2 | 6--12 | +0.3 -0.5 |

110 | 110 | +1 -2 | 6--12 | +0.3 -0.5 |

120 | 120 | +1 -2 | 6--20 | +0.3 -0.5 |

125 | 125 | +1 -2 | 6--20 | +0.3 -0.5 |

130 | 130 | +1 -2 | 6--20 | +0.3 -0.5 |

140 | 140 | +1 -2 | 6--20 | +0.3 -0.5 |

150 | 150 | +1 -2 | 6--20 | +0.3 -0.5 |

- Q: How do you determine the dimensions of a steel flat bar?

- To determine the dimensions of a steel flat bar, you need to measure its width, thickness, and length using a measuring tape or a caliper.

- Q: Are steel flat bars suitable for creating industrial equipment or machinery?

- Yes, steel flat bars are suitable for creating industrial equipment or machinery. They offer excellent strength and durability, making them ideal for constructing various components and structures in the industrial sector. Steel flat bars can be easily fabricated, welded, and machined to meet specific requirements, ensuring the quality and reliability of the equipment or machinery being produced.

- Q: What are the different types of coatings available for steel flat bars?

- There are several types of coatings available for steel flat bars, including galvanized, powder coated, painted, and epoxy coated.

- Q: How do steel flat bars perform under impact or shock-loading conditions?

- Steel flat bars exhibit excellent performance when subjected to impact or shock-loading due to their exceptional strength and durability. The inherent characteristics of steel, including its high tensile strength and resilience, render it an optimal material for withstanding abrupt and forceful impacts. When faced with impact or shock-loading, steel flat bars possess the capability to absorb and distribute the energy uniformly throughout their structure. This capacity helps to avert localized failure and guarantees the even dispersion of the force. Consequently, steel flat bars are less prone to deformation, fracture, or breakage under these circumstances. Moreover, steel showcases remarkable resistance to fatigue, thereby enabling it to endure repetitive impacts without experiencing significant deterioration in its performance. This quality makes steel flat bars highly suitable for applications where dynamic loads or sudden impacts are prevalent, such as in the realms of construction, automotive manufacturing, or industrial machinery. Nevertheless, it is essential to acknowledge that the specific performance of steel flat bars under impact or shock-loading conditions may vary depending on several factors, including the quality of the steel utilized, the dimensions of the flat bar, and the particular application involved. Hence, it is crucial to carefully consider the specific requirements and seek guidance from experts or engineers to ensure the appropriate steel grade and design are employed for the intended purpose.

- Q: Can steel flat bars be used in the construction of buildings?

- Indeed, buildings can be constructed using steel flat bars. Owing to their robustness, endurance, and adaptability, steel flat bars are frequently employed in construction. They offer structural reinforcement and are commonly utilized for framing, reinforcement, and support systems within buildings. Steel flat bars can be conveniently fashioned, welded, and molded to fulfill the precise demands of a construction endeavor. Furthermore, they possess resistance against corrosion, fire, and pests, rendering them an excellent option for constructing enduring and robust buildings.

- Q: What are the different methods of surface protection for steel flat bars?

- There are several methods of surface protection for steel flat bars to prevent corrosion and damage. Some of the most common methods include: 1. Galvanization: This process involves coating the steel flat bars with a layer of zinc, either by hot-dip galvanizing or electroplating. The zinc acts as a sacrificial layer, protecting the steel from rust and corrosion. 2. Powder coating: Powder coating is a dry finishing process where a powdered paint is electrostatically applied to the steel flat bars. The bars are then heated, causing the powder to melt and form a durable, protective coating. Powder coating provides excellent resistance to scratches, chipping, and fading. 3. Painting: Painting the steel flat bars with a suitable primer and topcoat is another effective method of surface protection. The primer helps to adhere the paint to the steel, while the topcoat provides a protective layer against corrosion, UV radiation, and other environmental factors. 4. Varnishing: Varnishing involves applying a clear coating to the surface of the steel flat bars. This coating forms a protective film that prevents moisture and air from reaching the steel, thereby reducing the risk of corrosion. 5. Epoxy coating: Epoxy coatings are often used in industrial and marine applications for their excellent resistance to chemicals, moisture, and abrasion. These coatings can be applied as a single or multiple layer system, providing a long-lasting and durable protection for steel flat bars. 6. Metal plating: Metal plating, such as chrome plating or nickel plating, can be used to protect steel flat bars from corrosion. The plating process involves depositing a layer of metal onto the surface of the bars, creating a barrier against moisture and oxidation. 7. Anodizing: Anodizing is commonly used for aluminum, but it can also be applied to steel flat bars. This process involves creating a controlled oxide layer on the surface of the steel through electrolysis. The resulting layer provides enhanced corrosion resistance and can be further sealed with a protective coating. It is important to select the most appropriate surface protection method based on the specific application, environment, and desired durability of the steel flat bars. Regular maintenance and inspection are also crucial to ensure the continued effectiveness of the chosen protection method.

- Q: Are steel flat bars susceptible to warping or bending?

- Yes, steel flat bars are susceptible to warping or bending under certain conditions. Steel is a strong and durable material, but it is not completely immune to deformation. When subjected to excessive stress, heat, or improper handling, steel flat bars can warp or bend. This can occur during the manufacturing process, transportation, or when the bars are exposed to heavy loads or extreme temperature changes. To minimize the risk of warping or bending, it is crucial to handle and store steel flat bars properly, avoid excessive stress or heat, and follow the manufacturer's guidelines for usage and maintenance.

- Q: Are steel flat bars suitable for outdoor furniture?

- Steel flat bars are indeed a suitable option for outdoor furniture. They possess qualities of durability and strength, enabling them to endure diverse weather conditions and making them an excellent choice for outdoor utilization. By providing stability and support to furniture frameworks, steel flat bars ensure the longevity and resilience of the pieces, safeguarding them against damage and deterioration. Furthermore, steel can be treated with protective coatings like powder coating or galvanization, thereby enhancing its resistance to rust and corrosion and prolonging its lifespan. The versatility of steel further enables a broad spectrum of design possibilities, rendering it a highly favored selection for outdoor furniture.

- Q: What is the maximum length available for steel flat bars?

- The maximum length available for steel flat bars can vary depending on the supplier and manufacturer. However, in general, steel flat bars are commonly produced in standard lengths of 20 feet or 6 meters. These lengths are widely available and suitable for a wide range of applications. Additionally, it is worth noting that some suppliers may offer custom cutting services, allowing customers to request specific lengths according to their project requirements.

- Q: What are the common tolerances for steel flat bars?

- The common tolerances for steel flat bars can vary depending on the specific requirements and standards set by the industry or customer. However, there are generally accepted tolerances that are widely used in the manufacturing and construction sectors. In terms of thickness, the common tolerance for steel flat bars is typically ± 0.005 inches or ± 0.13 millimeters. This means that the actual thickness of the flat bar can deviate by up to 0.005 inches or 0.13 millimeters from the specified thickness. For width, the common tolerance is usually ± 0.020 inches or ± 0.5 millimeters. This means that the actual width of the flat bar can vary by up to 0.020 inches or 0.5 millimeters from the specified width. In terms of length, the common tolerance is typically ± 0.125 inches or ± 3 millimeters. This means that the actual length of the flat bar can deviate by up to 0.125 inches or 3 millimeters from the specified length. It is important to note that these common tolerances may vary depending on the specific application, industry standards, or customer requirements. Therefore, it is always advisable to consult the relevant standards or specifications to determine the precise tolerances for a particular steel flat bar.

Send your message to us

SS400 Q235B hot rolled steel flat bar Slitting flat bar galvanized flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords