SS 904L Seamless Stainless Steel Pipe in Wuxi ,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

316 stainless steel pipe

Product Description

Name | Stainless Steel Seamless & Welded Tube &Pipe | |||||

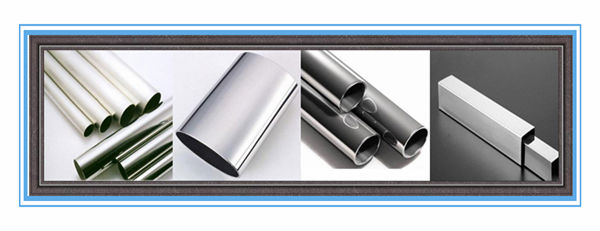

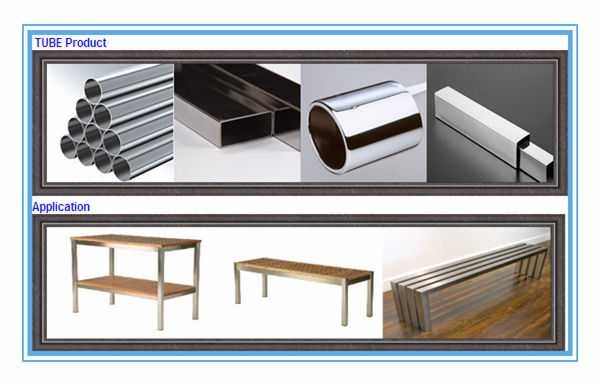

Items | Square tubes, round tubes, oval pipes, special shaped pipes, empaistic pipes, fittings | |||||

Standard | ASTM A554, A249, A269 and A270 | |||||

Material Grade | 201: Ni 0.8%~1% | |||||

202: Ni 3.5%~4.5% | ||||||

304: Ni 8%, Cr 18% | ||||||

316: Ni 10%, Cr 18% | ||||||

316L: Ni10%~14% | ||||||

430: Cr16%~18% | ||||||

Outer Diameter | 9.53mm--159mm | |||||

Thickness | 0.3mm - 3.0mm | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Outer Diameter: +/- 0.2mm | |||||

b) Thickness: +/- 0.02mm | ||||||

c) Length: +/- 5mm | ||||||

Surface | 180G, 240G, 320G Satin / Hairline 400G, 600G Mirror finish | |||||

Application | handrail,railing, staircase, weldmesh screen,door,window, balcony,fence,bench,furniture,etc | |||||

Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT | |||||

Chemical Composition of Material | Material

Composition | 201 | 202 | 304 | 316L | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.035 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 13-15 | 14-17 | 18-20 | 16-18 | 16-18 | |

Ni | 0.7-1.1 | 3.5-4.5 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <105< span=""> | <100< span=""> | <90< span=""> | <90< span=""> | ||

Our Work shop

Our products:

Definition of stainless steel(Adopted form Wikipedia)

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable",

is defined as a steelalloy with a minimum of 10.5% to 11% chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does,

but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity,

or poor circulation environments. It is also called corrosion-resistant steel or CRES

when the alloy type and grade are not detailed, particularly in the aviation industry.

There are different grades and surface finishes of stainless steel to suit the environment

the alloy must endure. Stainless steel is used where both the properties of steel

and resistance to corrosion are required.

- Q: Can stainless steel pipes be insulated with asbestos?

- No, stainless steel pipes should not be insulated with asbestos. Asbestos is a hazardous material that has been linked to serious health risks, including lung diseases and cancer. It is important to use safe and non-toxic insulation materials when insulating pipes to protect both the environment and human health.

- Q: What is the difference between Type 304L and Type 316L stainless steel pipes?

- Type 304L and Type 316L stainless steel pipes are commonly chosen for a variety of uses due to their ability to resist corrosion. However, they differ in their composition and performance in specific settings. The primary distinction lies in their alloy content. Type 304L stainless steel contains 18-20% chromium and 8-12% nickel, whereas Type 316L stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The inclusion of molybdenum in Type 316L enhances its corrosion resistance, particularly in environments with high chloride concentrations. As a result, Type 316L is more suitable for applications where the pipes will come into contact with seawater, brine, or other harsh chemicals. Another factor that sets them apart is their mechanical properties. Type 316L stainless steel has slightly higher tensile strength and yield strength compared to Type 304L. It also exhibits better creep and stress rupture properties, making it more appropriate for high-temperature uses. However, for most general purposes, Type 304L is still a good choice, offering excellent durability and longevity. When it comes to cost, Type 316L stainless steel pipes are typically more expensive than Type 304L due to the additional alloying elements. Therefore, the decision between the two will depend on the specific requirements of the application, taking into account factors such as the corrosive environment, temperature, and budget. Overall, while both Type 304L and Type 316L stainless steel pipes provide excellent corrosion resistance, Type 316L offers superior performance in more aggressive environments and higher temperatures. It is advisable to consult with a materials expert or engineer to determine the most suitable stainless steel pipe for a particular application.

- Q: How do stainless steel pipes compare to polyvinyl chloride pipes?

- Stainless steel pipes have a higher durability and can withstand higher pressures and temperatures compared to polyvinyl chloride (PVC) pipes. Additionally, stainless steel pipes are resistant to corrosion, making them suitable for a wide range of applications, including in harsh environments. On the other hand, PVC pipes are lightweight, easy to install, and more affordable. However, they are not as durable as stainless steel and have limitations in terms of pressure and temperature resistance. Ultimately, the choice between stainless steel and PVC pipes depends on the specific requirements and conditions of the project.

- Q: What are the limitations of using stainless steel pipes?

- Some limitations of using stainless steel pipes include their higher cost compared to other materials, their susceptibility to corrosion in certain environments, and their lower thermal conductivity compared to materials like copper. Additionally, stainless steel pipes may be more difficult to cut and weld, and their strength and durability may vary depending on the specific grade of stainless steel used.

- Q: Are stainless steel pipes resistant to sulfide stress corrosion cracking?

- Generally, stainless steel pipes exhibit resistance to sulfide stress corrosion cracking (SSC). This is due to the high chromium content in stainless steel, which leads to the formation of a protective oxide layer on the material's surface. This oxide layer acts as a barrier against corrosive substances, including sulfides, preventing their penetration into the steel. Furthermore, stainless steel pipes are often alloyed with other elements such as molybdenum and nickel, which further enhance their corrosion resistance. However, it is crucial to note that the degree of resistance to SSC can vary based on the specific grade and composition of stainless steel utilized. Consequently, it is vital to select the appropriate stainless steel grade specifically designed to withstand sulfide stress corrosion cracking in the desired application.

- Q: Can stainless steel pipes be used for food storage facilities?

- Indeed, food storage facilities can utilize stainless steel pipes. The reason behind this preference lies in the durability, corrosion resistance, and hygienic properties of stainless steel. Its resistance to reacting with food or emitting harmful substances renders it safe for storing diverse food products. Moreover, stainless steel pipes are easily maintainable and cleanable, which guarantees the utmost hygiene in food storage facilities. Additionally, stainless steel's resistance to high temperatures makes it appropriate for storing both hot and cold food items. All in all, stainless steel pipes prove to be an exceptional option for food storage facilities on account of their safety, durability, and hygienic attributes.

- Q: What is the difference between polished and unpolished stainless steel pipes?

- The primary distinction between polished and unpolished stainless steel pipes lies in their appearance and surface finish. Polished stainless steel pipes have undergone a polishing procedure, which enhances their visual appeal by creating a sleek, glossy, and reflective surface. This procedure involves the use of abrasive materials or compounds to eliminate any imperfections, scratches, or flaws on the stainless steel surface. On the contrary, unpolished stainless steel pipes possess a rougher, less lustrous, and more industrial-looking surface. They have not undergone the polishing process and therefore maintain their original surface finish, which may have slight imperfections, scratches, or a matte appearance. The choice between polished and unpolished stainless steel pipes depends on the desired application and aesthetic preference. Polished stainless steel pipes are commonly utilized in industries such as architecture, interior design, and food processing, where a visually pleasing and hygienic surface is necessary. Conversely, unpolished stainless steel pipes are frequently employed in applications where appearance is not a priority, such as industrial or structural uses. It is important to note that the performance and durability of both polished and unpolished stainless steel pipes are comparable, as the polishing process does not impact the inherent corrosion resistance and strength of the stainless steel material. Ultimately, the decision between polished and unpolished stainless steel pipes is based on the specific requirements and intended use of the pipes.

- Q: How do stainless steel pipes compare to nickel alloy pipes?

- Stainless steel pipes and nickel alloy pipes are both widely used in various industries for their corrosion resistance properties, high strength, and durability. However, there are some key differences between these two materials that should be considered when comparing them. One of the primary differences lies in their composition. Stainless steel pipes are primarily made of iron and chromium, with the addition of other elements such as nickel and molybdenum to enhance their corrosion resistance. On the other hand, nickel alloy pipes are predominantly made of nickel, with the addition of other elements such as chromium, iron, and molybdenum. In terms of corrosion resistance, both stainless steel and nickel alloy pipes offer excellent protection against corrosion. However, nickel alloy pipes are known to provide superior resistance to a wider range of corrosive environments, including highly acidic and alkaline conditions. This makes nickel alloy pipes more suitable for applications where extreme corrosion resistance is required, such as in chemical processing plants. Another factor to consider is the mechanical strength of the pipes. Stainless steel pipes are known for their high strength, making them suitable for applications that require structural integrity and the ability to withstand high-pressure environments. Nickel alloy pipes, on the other hand, offer even greater strength and toughness, making them ideal for applications that involve high temperatures and extreme conditions, such as in the oil and gas industry. Cost is another aspect to consider when comparing stainless steel and nickel alloy pipes. Stainless steel pipes are generally more cost-effective and widely available compared to nickel alloy pipes. Nickel alloy pipes tend to be more expensive due to the higher cost of nickel and other alloying elements used in their production. Therefore, the choice between stainless steel and nickel alloy pipes often depends on the specific requirements of the application and the budget constraints. In conclusion, stainless steel pipes and nickel alloy pipes both offer excellent corrosion resistance and mechanical strength. While stainless steel pipes are more cost-effective and widely used in various applications, nickel alloy pipes provide superior corrosion resistance and strength in extreme conditions. Therefore, the choice between these two materials depends on the specific needs and requirements of the application at hand.

- Q: Can stainless steel pipes be insulated with polyphthalamide?

- Polyphthalamide cannot be directly used to insulate stainless steel pipes. Usually, polyphthalamide is utilized as a high-performance thermoplastic for injection molding applications, rather than as insulation for pipes. For insulating stainless steel pipes, commonly used materials include fiberglass, mineral wool, and foam insulation. These materials are designed to provide thermal insulation, prevent heat transfer, and offer protection against corrosion and condensation. If there is a need to insulate stainless steel pipes, it is advisable to choose a suitable insulation material specifically designed for pipe insulation, rather than attempting to use polyphthalamide, which is not commonly used for this purpose.

- Q: Can stainless steel pipes be used for heat exchangers?

- Yes, stainless steel pipes can be used for heat exchangers. Stainless steel is a popular choice for heat exchangers due to its high resistance to corrosion, durability, and excellent heat transfer properties. It can withstand high temperatures and pressure, making it suitable for various applications in industries such as chemical, food processing, and power generation.

Send your message to us

SS 904L Seamless Stainless Steel Pipe in Wuxi ,China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords