Special Steel ASTM1020 Carbon Structural Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

1.Chemical performance:

Model | C | Si | Mn | P | S |

GB45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | 0.030 | 0.030 |

2.Mechanical performance:

Strength of extension | 600MPA |

Yield point | 355MPA |

Elongation | 16% |

Contractibility rate | 40% |

Impacting energy | 39J |

3.Size tolerance:

Length tolerance | +100mm/-0mm |

diameter tolerance | +/-1.0mm |

Straightness | Max 6mm/m |

4.

specification | Outer Diameter:14mm-180mm |

Standard | GB,JIS,DIN,AISI,ASTM,ISO,NF |

Certificate | ISO9001-2008 |

Application | A) General service industries (petroleum, food, chemical, paper, fertilizer, Fabric, aviation and nuclear) B) Fluid, gas and oil transport C) Pressure and heat transmission D) Construction and ornament E) Boiler heat exchangers |

Test | flaw detection According to customers' requests |

Processing | Cold Drawn/Cold Rolled/Hot Rolled |

Packing | as your requirement |

trade term | FOB; CNF; CIF PORT: TIANJIN, China |

payment | T/T ,L/C,D/P |

delivery time | Within 15 DAYS |

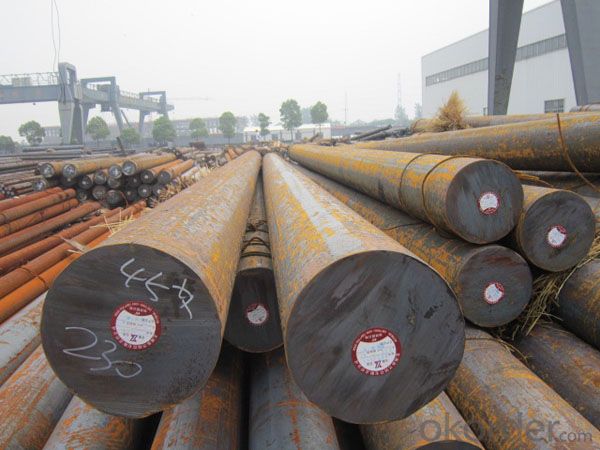

Product Show:

Workshop Show:

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the main applications of special steel in the energy storage industry?

- Special steel is widely used in the energy storage industry for various applications. One of the main applications is in the manufacturing of high-quality battery cases, where the steel's exceptional strength and corrosion resistance ensure the safety and longevity of the batteries. Additionally, special steel is used in the construction of energy storage systems, such as pumped hydro storage and compressed air energy storage, due to its durability and resistance to extreme conditions. Overall, special steel plays a crucial role in ensuring the efficiency, reliability, and safety of energy storage technologies in the industry.

- Q: Can special steel be used in the construction industry?

- Yes, special steel can be used in the construction industry. It offers several advantages such as high strength, durability, and resistance to corrosion, making it suitable for various applications in construction, including beams, columns, and reinforced concrete structures. Special steel can also provide cost-effective solutions by reducing the need for additional materials and maintenance.

- Q: How does special steel perform in terms of impact resistance?

- Special steel typically performs very well in terms of impact resistance. It is specifically designed to withstand high impact forces without deforming or breaking. This type of steel is often used in applications where strength and durability are crucial, such as in construction, automotive, and aerospace industries. Its superior impact resistance properties make it highly reliable and capable of withstanding heavy loads and sudden impacts.

- Q: How does special steel perform in high-temperature applications?

- Special steel performs exceptionally well in high-temperature applications. It has excellent heat resistance and can withstand extreme heat without losing its strength or shape. This makes it highly suitable for use in industries such as aerospace, power generation, and automotive, where it is exposed to high temperatures and thermal stress. Additionally, special steel exhibits good oxidation and corrosion resistance, ensuring its durability and reliability in these demanding conditions.

- Q: How does special steel contribute to improving product aesthetics?

- Special steel can contribute to improving product aesthetics in several ways. Firstly, special steel can be manufactured with unique finishes and textures, enhancing the overall visual appeal of a product. This can include brushed, polished, or matte finishes, adding a touch of sophistication and elegance. Secondly, special steel can be shaped and formed into intricate and precise designs, allowing for the creation of visually appealing and intricate product components. Additionally, the strength and durability of special steel can enable products to have sleek and slim designs, reducing bulkiness and enhancing the overall aesthetics. Overall, special steel offers designers and manufacturers a versatile material that can enhance the visual appeal and aesthetic quality of their products.

- Q: How does special steel contribute to the metalworking industry?

- Special steel contributes to the metalworking industry by offering enhanced properties such as increased strength, durability, and resistance to corrosion or heat. These unique characteristics make it suitable for a wide range of applications, including manufacturing of machinery, tools, and components used in various sectors like automotive, aerospace, construction, and energy. By providing superior performance and reliability, special steel helps improve productivity, efficiency, and safety in metalworking processes, ultimately driving innovation and advancement in the industry.

- Q: What are the different methods for improving the corrosion resistance of special steel?

- There are multiple techniques available to enhance the corrosion resistance of special steel. 1. Alloying: Adding alloying elements, like chromium, nickel, and molybdenum, to the steel composition is a widely used method. These elements create a protective layer on the steel surface, preventing corrosion. For instance, stainless steel contains a substantial amount of chromium, which forms a passive film that shields the steel from corrosive surroundings. 2. Surface treatments: Diverse surface treatments can be applied to special steel to augment its corrosion resistance. These treatments include electroplating, hot-dip galvanizing, and chemical passivation. Electroplating involves coating the steel with a layer of zinc or nickel, serving as a sacrificial anode that safeguards the steel from corrosion. Hot-dip galvanizing entails immersing the steel in molten zinc to form a durable and corrosion-resistant layer. Chemical passivation involves treating the steel with a solution that eliminates surface impurities and forms a protective oxide layer. 3. Protective coatings: The application of protective coatings can considerably enhance the corrosion resistance of special steel. Coatings like paint, epoxy, or polyurethane act as barriers, preventing moisture and corrosive substances from contacting the steel surface. These coatings can be applied through spray, dip, or powder coating methods. 4. Heat treatment: Modifying the microstructure of special steel through heat treatment improves its corrosion resistance. Processes like annealing, quenching, and tempering can alter the steel's properties, making it more resistant to corrosion. Heat treatment can also alleviate internal stresses that contribute to corrosion. 5. Environmental control: Controlling the environment in which the special steel is utilized can also aid in improving its corrosion resistance. This includes maintaining appropriate humidity levels, controlling pH, avoiding exposure to corrosive chemicals, and implementing effective ventilation systems. By minimizing the exposure of special steel to corrosive elements, its corrosion resistance can be enhanced. In conclusion, a combination of these methods can be employed to enhance the corrosion resistance of special steel, ensuring its durability and performance in corrosive environments.

- Q: What are the different international standards for special steel?

- There are several international standards for special steel, including the American Society for Testing and Materials (ASTM) standards, the International Organization for Standardization (ISO) standards, and the European Standards (EN) standards. These standards define the chemical composition, mechanical properties, and testing requirements for various types of special steel, ensuring quality and consistency in their production and usage worldwide.

- Q: How does special steel contribute to the manufacturing of power generation equipment?

- Special steel plays a crucial role in the manufacturing of power generation equipment by offering exceptional strength, durability, and corrosion resistance. It is used to construct various components such as turbine blades, generator shafts, and pressure vessels, ensuring efficient and reliable power generation. Additionally, special steel's high temperature resistance enables it to withstand extreme operating conditions, ensuring the longevity and efficiency of power generation equipment.

- Q: What are the applications of high-strength low-alloy (HSLA) steel?

- High-strength low-alloy (HSLA) steel finds applications in various industries such as automotive, construction, and manufacturing. It is commonly used in the production of heavy machinery, bridges, pipelines, and offshore structures due to its excellent strength, toughness, and corrosion resistance. Additionally, HSLA steel is favored in the automotive industry for manufacturing lightweight yet durable components, enhancing fuel efficiency and overall vehicle performance.

Send your message to us

Special Steel ASTM1020 Carbon Structural Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords