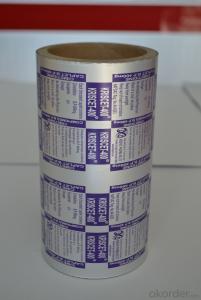

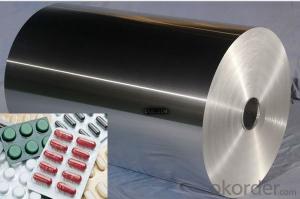

Aluminum Foil Food Bags with SP Laminated Film for Pharmaceutical Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 800 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

SP laminated strip pack manufactured by the unique production process laminated PET(or BOPP)/AL(or VMPET)/PE(or CPP) with special adhesives in well-equipped R 100,000 filter class GMP workshop, the quality of products under controlled by the ISO9001 quality management system, and the working environment through ISO 14000 certification. It has high barrier in resist-moisture, lights, oxygen, the PE of the inner surface can keep good heat insulation to make it own excellent air tightness, and then extend the preservative period of its contents and have some extensiveness and with standing pressure, and the most obvious trait is the performance of heat tightness at low temperature, especially applied to those drugs which can't be packed at high temperature One of the structures PET/AL/PE product can be perfectly printable.

2.Structure

Main PET(or BOPP)/AL(or VMPET)/PE(or CPP) components Laminated

3. Characters

high barrier in resist-vapor、all kinds of gases and lights;

PE of the inner surface can keep good heat insulation to make it own excellent air tightness, and extend the preservative period of its contents;

With extensiveness and standing pressure, and the performance of heat –sealing at low temperature, especially applied to those drugs which can't be packed at high temperature;

One of the structures PET/AL/PE product can be perfectly printable.

4.Main applications

It can be applied to the food, health products, drug, particle, powder chemicals and etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 40 working days can be served.

- Q: can use aluminum foil to shield the loudspeaker box wire?

- It does little help. In principle, since the loudspeaker wire is the terminal of audio device, common interference will not influence its sound effect. Therefore, a shield is not required. Common wires for strong electricity should be laid by poling. However, the wires for weak electricity such as telephone wire, reticle, TV wire or audio wire should be laid through other pipelines. Thus it has little correlation with strong electricity wire with smaller interference. When laying the loudspeaker wire near to the strong electricity wire or laying them at the same time, the insulation between the loudspeaker wire and strong electricity should be taken as a priority. It is recommended to lay the loudspeaker wire at a distance from the strong electricity wire in case of electric leakage.

- Q: When cooking split peas, I was told to use a small sterling silver or glass bowl covered with aluminum or a glass top.I was told any glass that is safe for the oven is safe for use in a pressure cooker.So I got a small baking glass pot with glass top and was about to use it,Then I find the baking glass pot directions say not to use it on the stove topSo is this still safe to use in the pressure cooker or not? Anybody with experience?I don't want to use stainless steel because I can't find any small with top and I don't use aluminum because it's toxic.Thanks

- I can only say this once: DO NOT UNDER ANY CIRCUMSTANCES EVER PUT GLASS IN A PRESSURE COOKER ON HEAT!!! :-o First, glass (corningware, glass bakeware, etc.) has been known to explode due to temperature fluctuationsYou can google thisThere have been lawsuits and severe injuriesGlass/corningware can NEVER go on a stove top everNext, while pressure cookers are getting safer, due to their nature of being a pressure cooker, they can still be very dangerous!!! My mom used them all the time, and one time while she was in the kitchen at the sink with the pressure cooker on the stove, the thing explodedLiterally, the lid broke off by itself and hit the ceiling and all the ingredients went flyingIt almost gave her a heart attackImagine if there was glass in itoh my godPlease don't EVER put glass in one.

- Q: How much energy is required to manufacture it? Under what conditions is it mined? Is it recycled generally? In general, is it green or not?

- Done that, got taken in the back room for a spankWas worth it to get the spank though.

- Q: i would like to make a silencer for a ruger 10/22

- over at charlies but we finaly figured it out wasnt no good he got arrested been poachin at nite all smug and such then in court we seen the signlanguage lady telling the judge for charley that he had signed that , he wrote for plans to, they came rolled up, so he put them on end of that 06 and went huntin thensigned that he never heard a thing,,and wonderded how they knew, he was down in the grave yard shootin deer as every body there was dead already,

- Q: Write an electron configuration for an aluminium ion in an excited state (in orbital format)

- 1s2 2s2 2p6 because its lost 3 electrons

- Q: I get these low sodium black eyed peas organic I believe (have a little bit of seaweed in them) well earlier I opened the can, scooped out a bit for a salad, and then put the can in the refrigerator without a lid or anythingwhat will happen from doing this? If I was to cover it with paper towel would I be okaY? Do they need to be in another container? I have no aluminum foil or money for that I'm just wonderingand if they need another container could I just use a glass bowl and cover them with paper towel? and if so how tightly sealed does the paper towel need to be? could I drape it over or do I need a rubber bandplease help me ive been drunk for many years now im sober and dont know how to livethankyou

- You should never store an open can in the fridgeThis allows bacteria to get inside the foodAlso if it isn't covered your food can pick up odors from the fridge and then they will start to taste badTransfer your peas to a plastic container with a lid or just a bowl with plastic wrapIf you don't have plastic wrap you can use the paper towel but you should use two and secure it with a rubber bandI hope this helps.

- Q: If someone says he is working with Aluminum, and he works outside, what does that mean? What is his occupation?

- This Site Might Help YouRE: Herb grilled chicken - what's good for sides? We have a friend coming over for football foodI've got some chicken breasts marinating in a garlic/herb mixture gonna cook those on the charcoal grillWhat are some good sides to go with? It's too cold for traditional bbq sides I want something different than mashed potatoes .

- Q: ok do you no wear i can find anything that looks like an astronaut costum before wednesday?!?!?!?!?

- best bet give it a bath place the cheese cake in a pan and pour water in the pan about a 2 inches that should do itlot of times if you over mix it cracks too

- Q: I'm trying to prepare a lab for my students where they synthesize alumI have measured out 1 gram of aluminum foil and torn it into small piecesI added 25 ml of 3M KOH to the aluminum foilAll the labs I have looked at say that after a few minutes a reaction will take place and it will turn blackFor me, nothing is happeningIt just sits thereAny suggestions? I'm using Food Lion brand aluminum foilI just made the KOH solution.

- older type of insulation is rock wool was a new idea, then but not very good go with a Blown fiberglass insulation the thicker the better

- Q: Powdered aluminum is used in the thermite reaction for welding metals, so what role does the powdered aluminum play in this reaction?

- Thermite is a pyrotechnic composition of aluminium powder and a metal oxide which produces an aluminothermic reaction known as a thermite reaction. It is not explosive, but can create short bursts of extremely high temperatures focused on a very small target for a short period of time. **** The aluminium reduces the oxide of another metal, most commonly iron oxide, because aluminium is highly combustible: Fe2O3 + 2Al - 2Fe + Al2O3 + Heat The products are aluminium oxide, free elemental iron, and a large amount of heat. The reactants are commonly powdered and mixed with a binder to keep the material solid and prevent separation.

Send your message to us

Aluminum Foil Food Bags with SP Laminated Film for Pharmaceutical Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 800 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords