Silicon Carbide Ceramic Filter Plate for Foundry Cast

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

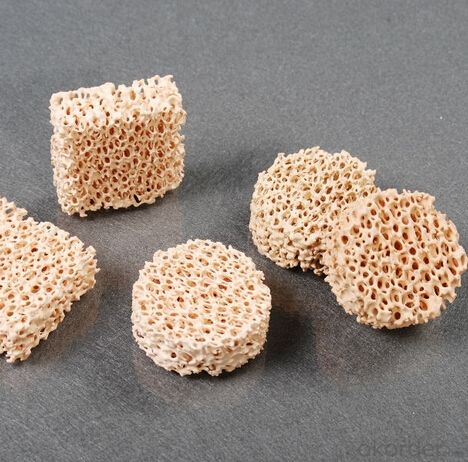

1.Production of ceramic foam filter

Ceramic Foam filters are just developed as a new type molten metal filter to decrease casting flaw in recent years. With its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance, Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, Bronze casting, etc.

2. Functions of ceramic foam filter

1). Thermal and chemical stability in high temperature,avoiding the chemical reaction with the filtered molten metal;

2). High porosity and good mechanical strength in high temperature due to its pure ceramic composite;

3). Low head loss,easy operation,energy-saving;

4). Making metal liquid flowing at stable speed and avoiding the sputtering and backset,thus increasing the surface quality of the cast part,preventing the pore disfigurement and finally lower down the unqualified rate;

5). Various sizes,shapes,apertures are available for kinds of foundry technique.

3.Physical and chemical properties

Silicon Carbide Foam Filters Data Sheet | ||||||

Material/Item | Density | Porosity | Refractoriness | compressive strength at Normal Tem. (≥Mpa) | Thermal Shock Resistance (time/1100 º C) |

Color |

Alumina | 10-20 | 80-87 | 1500 | 1.0 | ≥ 6 | Gray-Black |

Common specifications and sieving capacity

Specifications( mm) | Biggest filtering ability (Kg) | Molten Iron Velocity(Kg/s)

| ||

Ductile Iron | Gary Iron | Ductile Iron | Gary Iron | |

(30~200)X(50~200)X22 | 30~450 | 60~900 | 3~36 | 4~54 |

200x200x40 | 800 | 1600 | 64 | 95 |

Dia40X11 | 20 | 40 | 2 | 3 |

(Dia40~150)X22 | 35~350 | 70~700 | 2~25 | 4.5~38 |

Dia 200X40 | 620 | 1240 | 44 | 67 |

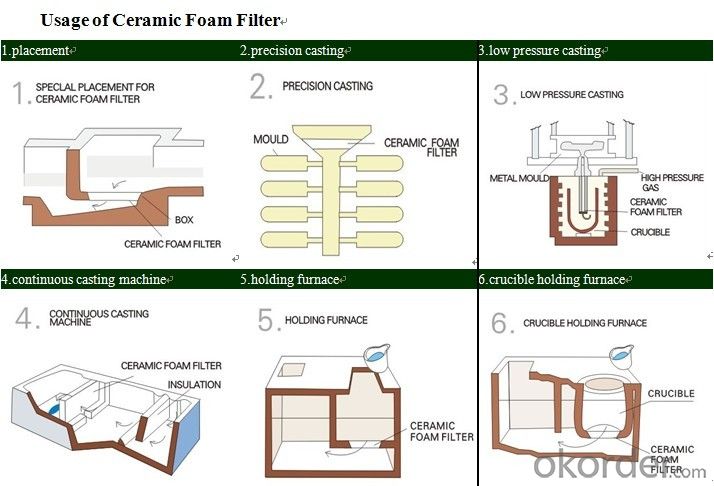

4.Usage of ceramic foam filter

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- The shape and mechanism of the ceramic filter are similar to those of the disc vacuum filter, but the filter media are different. The filter medium of ceramic filter is the ceramic filter plate, it can produce the micro capillary effect and capillary force in micropores is higher than the general vacuum applied force, so that the pores keep full of liquid state, so no matter what the circumstances, the air does not pass through the ceramic filter plate, so that the ceramic filter solid-liquid separation of low energy consumption, and high vacuum.

- Q: What are the poor filtration effects of vacuum disc filters?

- With the increase of the material level of the ceramic filter trough, the suction time of the ceramic filter plate in the vacuum zone increases, the thickness of the slurry increases and the productivity increases. But the drying time is relatively short, the water content of the concentrate will be increased. Select the best material level to ensure the production capacity and concentrate moisture requirements.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Generally, the vacuum degree of ceramic filter is about -0.08MPa. Sufficient vacuum pressure is only a prerequisite for a good ceramic suction effect. Besides vacuum, the other factors may affect the suction effect:Vacuum display table fault, the difference between the display value and the actual data is great.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter automatic control system: control system through the metering pump will be concentrated nitric acid automatic mixing ceramic filter plate into nitrate after proportioning through the pipeline, so that it can be dissolved, dredge the blockage in the most microporous ceramic filter plate. This is the ceramic filter plate pickling, pickling, acid dosage should be sufficient as little pickling effect.

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- Beneficiation of ceramic filter, the technical parameters are normal, but the water will fill in groove is what reason

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

Send your message to us

Silicon Carbide Ceramic Filter Plate for Foundry Cast

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords