Ceramic Fiber Blanket Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

various density and thickness

used for industrial furnace and the sealing and insulating material of expanded gaps of furnace

Description

Ceramic Fiber Blanket is made by continuous processing method. The fiber interweave shapely after being needled. It has excellent tensile strength. The blanket do not contains any bonding agent.

Ceramic Fiber Blanket not only can resist the chemical species, but also the hydrofluoric acid, phosphoric acid and strong base. The Fiber Blanket have excellent capability of resisting the oil. After being dried ,it will repossess the thermal characteristic and the physical feature.

Our needled blanket has various density and thickness so that clients can have many choices. Which will bring the perfect insulating framework and profit.

Characteristic

Excellent Chemical Stability

Excellent Thermal Stability

Excellent Tensile Strength

Low Thermal Conductivity

Low Heat Storage

Product Series

1. 1050 Ceramic Fiber Spun Blanket HLGX-112

2. 1260 Ceramic Fiber Spun Blanket HLGX-212

3. High Purity Ceramic Fiber Spun Blanket HLGX-312

4. High Aluminum Ceramic Fiber Blown Blanket HLGX-412

5. High Zirconium Ceramic Fiber Spun Blanket HLGX-512

Technical Index

Classification Temperature | 1050 | 1260 | 1400 | |||||||

Code | HLGX-112 | HLGX-212 | HLGX-312 | HLGX-422 | HLGX-512 | |||||

Shrinkage on Heating (%) | 950°C×24h≤-3 | 1000°C×24h≤-3 | 1100°C×24h≤-3 | 1200°C×24h≤-3 | 1350°C×24h≤-3 | |||||

Theoretical Thermal Conductivity (W/m·k) (128kg/m3) | (200°Caverage) | 0.045-0.060 | 0.052-0.070 | |||||||

(400°Caverage) | 0.085-0.110 | 0.095-0.120 | ||||||||

(600°Caverage) | 0.152-0.20 | 0.164-0.210 | ||||||||

Theoretical Density (kg/m3) | 96/128 | 128 | 96/128 | |||||||

Specification (mm) | 3600/7200/15000(L)×610/1220(W)×10/20/25/30/40/50(T) (422δ: 10/20/25/30) | |||||||||

Tensile Strength(25mm thick)MPa | ≥0.04 | |||||||||

AL2O3(%) | ≥44 | ≥45 | ≥45 | 52~55 | 38~40 | |||||

ZrO2 | - | 15~17 | ||||||||

AL2O3+SiO2(%) | ≥96 | ≥97 | ≥99 | ≥99 | — | |||||

AL2O3+SiO2+ZrO2(%) | — | — | — | — | ≥99 | |||||

Fe2O3(%) | ≤1.2 | ≤1.0 | ≤0.2 | ≤0.2 | ≤0.2 | |||||

K2O+Na2O(%) | ≤0.5 | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |||||

Package | Plastic Bag Inside, Carton Box Outside | |||||||||

Quality Control System | ISO9001-2000, ISO14001-1996 | |||||||||

Welcome your enquiry at any time. We are pleased to serve you with high quality product in most competitive price th professional service.

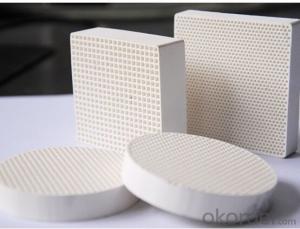

- Q: Performance advantages of ceramic filter

- The base is provided with a slime recovery rotor, the rotor consists of a shaft, multistage ceramic filter disc, stripper plate, multi section water connecting pipe, pipe support plate, negative pressure connecting component dynamic disk; the rotor is in the recovery of coal slime liquid tank; the ceramic filter disc by a plurality of ceramic microporous plate cavity, located on the same axis of a ceramic plate cavity communicated through the outlet connection pipe.

- Q: Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

- Q: What are the materials that make up the ceramic mold?

- At present, the commercialized porous ceramic membranes are mainly composed of 3 types: flat plate, tubular and multi channel. Flat film is mainly used for small-scale industrial production and laboratory research. The tubular membrane is combined with rice to form a heat exchanger similar to a column tube heat exchanger, which can increase the loading capacity of the membrane, but is gradually withdrawn from industrial application due to its strength problem. The size of the applied ceramic membrane usually adopts a multi channel configuration, that is, a plurality of channels are distributed on a circular cross-section, and the number of general channels is 7, 19 and 37. The main business of the inorganic ceramic membrane preparation technology: using solid particle sintering preparation carrier and microfiltration membrane by sol-gel method in the preparation of ultrafiltration membrane: glass membrane by phase separation method: using special technology (such as chemical vapor deposition, electroless plating, etc.) the preparation of microporous membrane or dense membrane. Its basic theory involves colloid and surface chemistry, material chemistry, solid state ion science, material processing and so on.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: What is the working pressure of the ceramic filter?

- The backwash pressure is the size of the backwash of the ceramic filter during recoil stage, and the recoil pressure is generally less than 0.12MPa. The greater the pressure, the better the recoil effect, the better the service life and the suction effect of the ceramic filter plate, and the worse the service life and the suction effect of the ceramic filter board. The backwash pressure of the ceramic filter shall be no less than 0.07MPa.

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q: What are the reasons for the program alarm of ceramic filter?

- The vacuum failure may be the vacuum pump failure, the vacuum pipeline leakage, the ceramic filter plate rupture or the connection water leakage, the backwash system is generally before the filtration water pressure is insufficient, the filter core plug and so on. Vacuum suction deficiency will lead to poor effect or even suction; cleaning standards will accelerate the ceramic filter clogging, ceramic filter clogging even if the vacuum suction is normal, will not even bad effect such as cake, jelly thin with high water content. Ceramic filter plate, hole plugging, discarding. Ceramic filter plate is life, under normal circumstances is about a year, such as pulp mud content, fine particle size or containing ingredients, cleaning is not easy to precipitate standards will reduce its life, when the ceramic filter plate close to the scrap, the suction effect will be worse. I hope my answer can help you.

- Q: What is the backwashing pressure of the ceramic filter?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

Send your message to us

Ceramic Fiber Blanket Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords