Silica Lime Bricks for Hot Blast Furnace Lightweight Silica Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Other |

| SiO2 Content (%): | 91 | MgO Content (%): | 0 | CaO Content (%): | 0 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 | SiC Content (%): | 0 |

| Model Number: | QG1.2 | Brand Name: | sunrise | size: | any size |

Packaging & Delivery

| Packaging Details: | wooden pallet |

| Delivery Detail: | 2 months |

Specifications

light weight fused silica refractory for hot blast furnace

1)Good acid erosion resistance.

2) High softening point with temp

light weight fused silica refractory for hot blast furnace

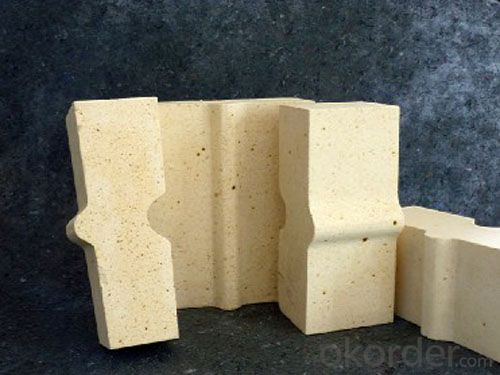

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size

1)Good acid erosion resistance.

2) High softening point with temperature.

3) No shrink in burn repeatedly.

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products

Item Brand Index | Light weight silica brick |

QG-1.2 | |

SiO2≥ | 91 |

Refractoriness | 1670 |

RUL(0.2 MPa)T1, °C | 1560 |

Apparent Porosity%≤ | ≥45 |

Cold Crushing Strength Mpa ≥ | 3.5 |

True Density g/cm3 ≤ | 2.39 |

Bulk Density g/cm3 ≤ | 1.20 |

Our factory product various kinds of refractory products. The products can be made according with the customers' requirement

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on. The properties and process of silica crystal with SiO2 transformation is closely related, therefore, the proportion of it is one of the important quality indexes of silica brick. General requirements below 2.38, high quality silica brick should be less than 2.35. The true density is small, reflecting a large number of scale quartz and square quartz in the brick, the residual quartz is small, so the residual line expansion is small, and the strength is decreased in useThe raw materials for the manufacture of silica brick. The higher the SiO2 content of silica raw material, the higher the refractoriness. The most harmful impurities are Al2O3, K2O, Na2O and so on. They seriously reduce the refractoriness of refractory products. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer (e.g. millscale, lime) and binder (such as molasses, sulfite pulp waste liquid), after mixing, molding, drying, sintering and other processes in the system.

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: Physical solid waste disposal

- Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products when firing, reduce cracks, improve the rate of finished products.

Send your message to us

Silica Lime Bricks for Hot Blast Furnace Lightweight Silica Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords