Silica Bricks for Carbon Furnace Channel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silica bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C and high refractoriness under load, It mainly used at high temperature area include arch and upside of hot stove and upside of checker.

Application:

1 Building materials for blast furnace

2 Building materials for hot-blast stove

3 Building materials for coke oven

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

Typical features:

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

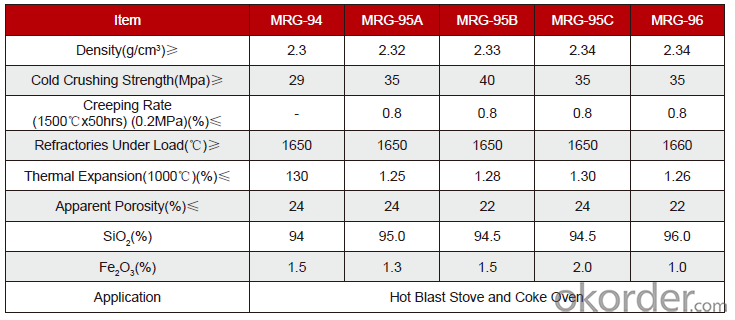

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations

- Q: The introduction of silica brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

Send your message to us

Silica Bricks for Carbon Furnace Channel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords