Fused Silica Bricks - High Quality Refractory Silica Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | silica |

| SiO2 Content (%): | 94%-96% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | Brand Name: | ZYC |

Packaging & Delivery

| Packaging Details: | On wooden pallets with plastic films cover |

| Delivery Detail: | According to customers' requirements |

Specifications

1. SiO2 :93%-96%.

2. Can according to customers' requirements.

3. Used for various industrial High temperature kilns.

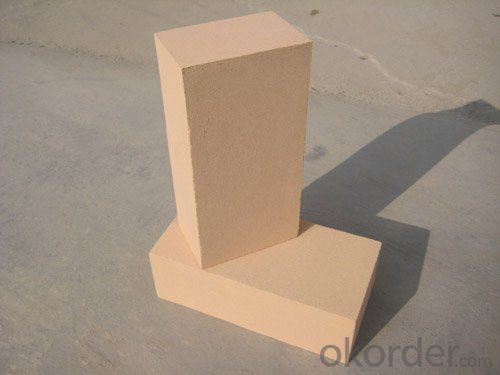

Silica brick,Refractory silica brick,Silicon brick

Characteristics:

1. High refractoriness.

2. Have a good fight acid slag erosion ability.

3. High volume stability.

General silica brick: Siliceous refractory products used for various large coke oven, glass kiln stove, hot air stove, etc. | |||

Item | GZ-96 | GZ-95 | GZ-94 |

SiO2 % ≥ | 96 | 95 | 94 |

Fe2O3 % ≤ | 1.0 | 1.2 | 1.4 |

Refractoriness °C ≥ | 1710 | 1710 | 1690 |

Apparent porosity % ≤ | 22 | 22 | 24 |

Cold crushing strength Mpa ≥ | 29.4 | 24.5 | 19.6 |

Refractoriness under load, 0.2MPa, °C ≥ | 1660 | 1650 | 1640 |

True density g/cm3 ≤ | 2.34 | 2.35 | 2.35 |

Silica brick for Hot-blast stove | ||

Item | Dome wall brick | Checker |

SiO2 % ≥ | 95 | 95 |

Cold crushing strength Mpa ≥ | 35 | 30 |

Apparent porosity % ≤ | 22 | 23 |

Creep rate(0.2MPa,1550°C,50h)% ≤ | 0.8 | 0.8 |

True density g/cm3 ≤ | 2.35 | 2.35 |

Thermal expansion(1000 °C)% ≤ | 1.26 | 1.26 |

Silica brick for Glass kiln | ||||

Item | BG-96A | BG-96B | BG-95A | BG-95B |

SiO2 % ≥ | 96 | 96 | 95 | 95 |

Fe2O3 % ≤ | 0.8 | 1.0 | 1.2 | 1.2 |

Apparent porosity % ≤ | 22 | 22 | 22 | 22 |

Refractoriness under load, 0.2MPa, °C ≥ | 1680 | 1670 | 1660 | 1650 |

True density g/cm3 ≤ | 2.34 | 2.34 | 2.35 | 2.35 |

Cold crushing strength Mpa ≥ | 30 | 30 | 30 | 30 |

Silica brick for coke oven | ||

Item | Furnace bottom,Furnace wall | Other |

SiO2 % ≥ | 94 | 94 |

Cold crushing strength Mpa ≥ | 30 | 25 |

Apparent porosity % ≤ | 22. | 24 |

Refractoriness under load, 0.2MPa, °C≥ | 1650(Cementation silica 1620) | 1650(Cementation silica 1620) |

Permanent linear Change 1450 °C,2h ≤ | 0—+0.2 | 0—+0.2 |

True density g/cm3 ≤ | 2.34 | 2.35 |

Thermal expansion(1000 °C)% ≤ | 1.28 | 1.30 |

Application:

Silica brick is mainly used for Coke oven, glass kiln, hot-blast stove, tunnel kiln,Acidic furnace non-ferrous metal smelting and some other thermotechnical equipment in good furnace building materials.

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- How to keep the brick masonry temperature not lower than 600 DEG C, while the exhaust temperature is not higher than 400 DEG C.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use,

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: The chemical composition of silica brick and its physicochemical index?

- ????Al2O3 SiO2??????fe2o3??????cao???????r2o93~98?0.5~2.5?;;?0.3~2.5??0.2~2.7;??1~1.5;

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

Send your message to us

Fused Silica Bricks - High Quality Refractory Silica Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords