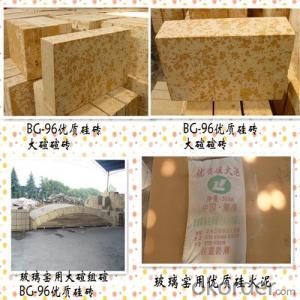

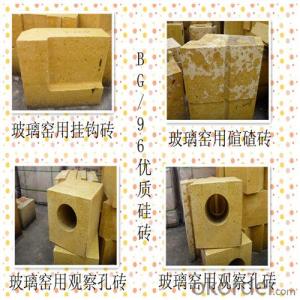

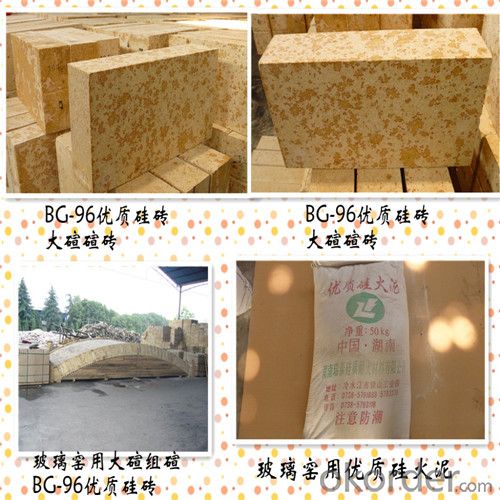

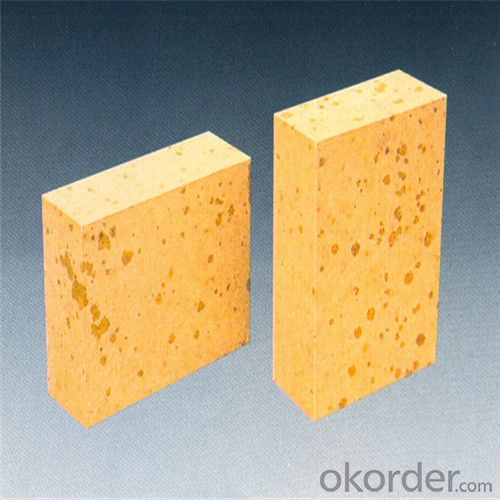

Silica Brick - High Compressive Strength Refractory Fused Silica Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description For Silica Brick:

Silica brick is made of quartz stone material, the content of SiO2 is above 93%,it has good resistance to acid slag and good heat conductivity. And the refractoriness is 1690~1710°C,RUL is beyond 1620°C.

SiO2 has different types of crystals in different temperatures, and the transform between the crystals will cause the change of the bulk. So there is a close contact between the changes of SiO2 crystals and the produce ,performance and usage of silica bricks. During the heating, there will be changes of the bulk ,and cristobalite changes most, then quartz, phosphorus quartz is the slowest of all and it also has good heat-conductivity.Coke oven should use the silica brick with small true density. And the phosphorus quartz is better than others.

Application For Silica Brick:

Mainly used in the construction of regenerative chamber, chute, combustion chamber, coking chamber, furnace roof etc. parts of the coke ovens.

Also be used for coke oven of coking chamber and combustion chamber partition, steel open hearth of regenerative chamber and sediment chamber, soaking furnace, glass melting furnace, refractory silica brick materials and ceramic firing kiln and kiln of the vault and other supporting parts. Also used in hot blast stove of high temperature bearing parts and acid open hearth furnace roof.

Advantage For Silica Fire Brick:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products.

FAQ

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the prod duction required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals. uction, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: Can not use it two brick

- The softening temperature is up to 1640~1670 DEG C, and the volume is stable at high temperature for a long time.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q: What are the main constituents of refractory bricks?

- Clay brick and clay brick are mainly composed of mullite (25% ~ 50%), glass phase (25% ~ 60%) and square quartz and quartz (up to 30%). Usually with hard clay as raw material, pre calcined mature material, and then with soft clay, semi dry or plastic molding, the temperature at 1300~1400 C fired clay brick products. Can also be added a small amount of water, glass, cement and other binders to make non burning products and amorphous materials. It is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.

- Q: The chemical composition of silica brick and its physicochemical index?

- Brick refers to the refractory products in more than 93% of the content of SiO2

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick - High Compressive Strength Refractory Fused Silica Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords