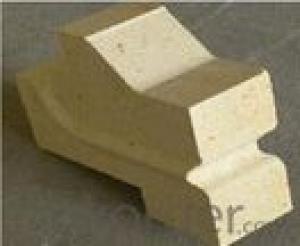

Silica Brick for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Characteristic:

1.High refractoriness under load

2.High temperature resistance

3.Corrosion resistance

Product Description

| Item | Coke Oven Silica Brick | Glass Furnace Silica Brick | Hot Blast Stove Silica Brick | |

| JJG-94 | JBG-95 | JBG-96 | JRG-95 | |

| SiO2 % | 94.5 | ≥95 | ≥96 | 95 |

| Fe2O3 % | 1.5 | ≤1.0 | ≤1.0 | 1.3 |

| CaO % | 2.5 | 2.2 | 2.2 | |

| Al2O3+Na2O+K2O % | ≤0.5 | ≤0.5 | 1 | |

| Refractoriness °C | 1710 | 1710 | 1710 | 1710 |

| Refractoriness under load T1,°C | 1650 | 1650 | 1660 | 1650 |

| Apparent porosity % | 22(24) | 22(24) | 22(24) | 22(24) |

| Cold crushing strength Mpa | 40(35) | 35(30) | 35(30) | 35(30) |

| True Density g/cm3 | 2.33 | 2.32 | 2.33 | 2.34 |

| Thermal Expansion % | 1000°C 1.28(1.30) | 1000°C ≤1.25 | 1000°C ≤1.25 | 1000°C 1.26 |

| Residual Quartz % | 1.0 | 1.0 | 1.0 | 1.0 |

| Creep rate % | 1550°C×50h(0.8) | |||

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: Can iron oxide be used as refractory material?

- Is widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: Brick

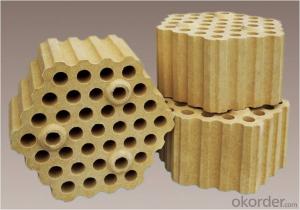

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords