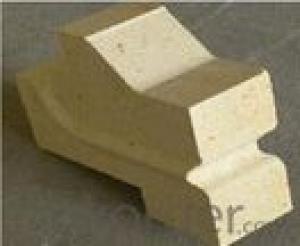

Silica Brick for High Duty Hot Air Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

The silica brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In metallurgy industry, it is adopted as the nozzle brick

Features

1.High purity

2.Long service life

3.Accurate size tolerance

4.Pure color

5. Luster appearance

6..Good thermal conductivity

7.Good creep resistance

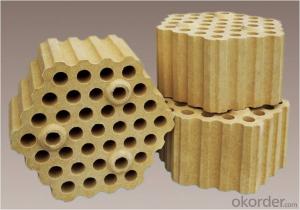

Application of the refractory silica bricks

Glass melting tank

Glass furnace

Hot-Blast Stoves

Hot Air Stoves

Physical & chemical indexes of the refractory silica bricks

General silica brick:Siliceous refractory products used for various large coke oven, glass kiln stove, hot air stove, etc. | |||

Item | GZ-96 | GZ-95 | GZ-94 |

SiO2 % ≥ | 96 | 95 | 94 |

Fe2O3 % ≤ | 1 | 1.2 | 1.4 |

Refractoriness °C≥ | 1710 | 1710 | 1690 |

Apparent porosity % ≤ | 22 | 22 | 24 |

Cold crushing strength Mpa ≥ | 29.4 | 24.5 | 19.6 |

Refractoriness under load, 0.2MPa, °C≥ | 1660 | 1650 | 1640 |

True density g/cm3 ≤ | 2.34 | 2.35 | 2.35 |

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Iron scale powder 0.45-0.55%, cement 0.9-1.1%, lime milk 6.5-7.5%, pulp 1.95-2.2%, the silica powder, perlite will be added to the wet mill in proportion, and then add iron scale powder, cement, dry roller 1-2 minutes later

Send your message to us

Silica Brick for High Duty Hot Air Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords