Silica Brick for Coke Oven/Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

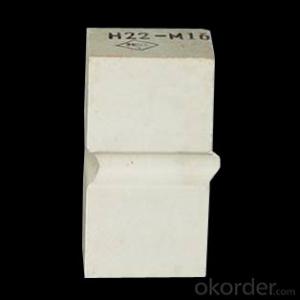

As the main refractories for coke oven, the quality is the key of energy saving, high efficiency, environmental and time of usage on coke oven. Over the years, We has been provided high-quality silica bricks for steel plants at Nagoya, Muroran and Oita of Nippon Steel and the products quality have been proved world-class products.The excellent performance silica brick has the following characteristics. The low creep, high refractories under load and low residual quartz contents, silicon bricks for hot stove of our company has been successfully applied to various types of hot stoves of major steel companies at home and abroad and the quality has been recognized by the clients. The silica bricks are the main fire-resistant material of coke oven. In order to keep its high quality, we take the best silica as raw material from Liaoning Shimen, Shanxi Wutaimountain, Henan Tiemen. With the multistage batching and best grain matching, our semi-manufactured goods are produced by the 300tons bricks pressing machine. The bottom,

Wall and top bricks are produced by 500tons bricks pressing machine. Every semi-manufactured and finished product-s are examined according to the national standard and marked it according to the tolerance.

Feature

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Technical Data

| Brand Item | GZ-95 | RG-95 | JG-94 | ||

| Dome & Wall brick | Checker | Sole & wall brick | Others | ||

| Refractoriness º C ≥ | 1710 | ||||

| Permanent liner change 1450 º C × 2h % | +0.2 0 | ||||

| Apparent Porosity (%) ≤ | 22 | 22 | 23 | 22 | 24 |

| True Density (g/cm3) ≤ | 2.37 | 2.35 | 2.35 | 2.34 | 2.35 |

| Cold Crush Strength (MPa) ≥ | 29.4 | 35 | 30 | 30 | 25 |

| Thermal Expansion(1000 º C ) % | 1.26 | 1.26 | 1.28 | 1.30 | |

| Refractoriness under Load 0.2MPa Ta( º C ) ≥ | 1650 | 1650 | 1650 | ||

| Chemical analysis SiO 2 % ≥ | 95 | 95 | 95 | 94 | 94 |

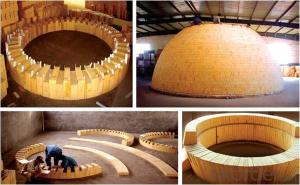

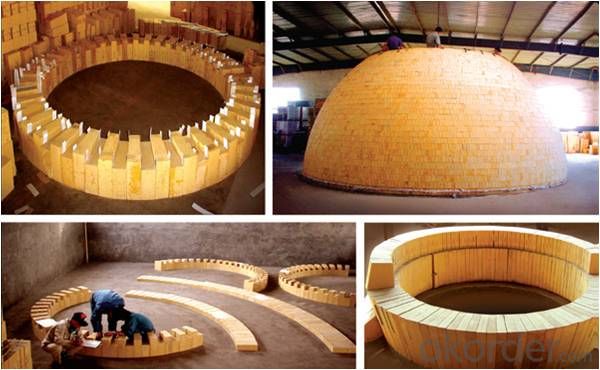

Photos for Applications

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Brick for Coke Oven/Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords