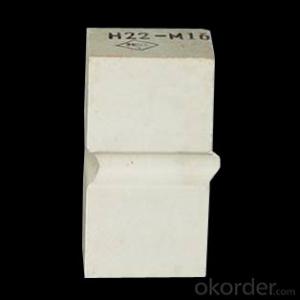

Silica Brick for Coke Oven Cmax-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Item | Speification | ||

| ASC-1 | ASC-2 | ASC-3 | |

| Al2O3 and MgO | ≥58 | Al2O3 and SiC≥80 | ≥68 |

| SiC | ≥10 | ≥10 | |

| C | ≥6 | ≥8 | ≥10 |

| Apparent porosity(%) | ≤10 | ≤10 | ≤10 |

| Bulk density(g/cm3) | ≥2.65 | ≥2.85 | ≥2.98 |

| Cold crushing strength(MPa) | ≥35 | ≥50 | ≥35 |

| Modulus of rupture at room temperature | ≥2 | ≥4 | ≥2 |

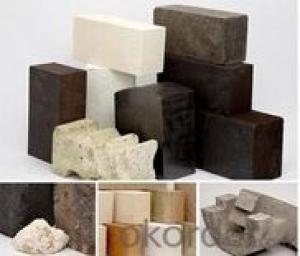

Alumina silicon carbide carbon brick using grade alumina, fused alumina, silicon carbide, graphite and high-pressure molding of additives, mainly for ordinary ladle, ladle desulfurization, Large torpedo car.

Alumina silicon carbide carbon brick as a composite refractories, Effective use of the high thermal capacity and strong resistance to slag erosion and magnesia carbon, low expansion, the biggest drawback is compensated magnesia poor chipping resistance.

Specifications

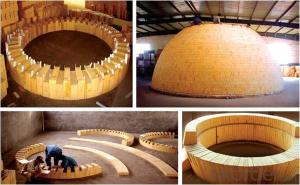

SILICA BRICK FOR COKE OVEN

1. NASDAQ listed company

2.stock code: ANNC

3. many patent products

4.pass ISO,GB,YB,DIN

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: High temperature refractory material?

- Basic refractories in Magnesium Oxide and calcium oxide as the main component, the main products are magnesia brick, magnesia chrome brick, magnesia zirconia brick, magnesia brick, magnesia spinel brick, magnesia calcium brick, dolomite brick and the latest development of magnesia spinel brick and so on. With Magnesium Oxide (MgO) more than 80% of the refractory brick called magnesia brick,

- Q: The formula in the refractory brick, and firing curve, who knows?

- By silica powder, 81-85%, perlite 15-19%, plus the total weight of the main raw materials of the following accessories

Send your message to us

Silica Brick for Coke Oven Cmax-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords