Silica Brick for Coke Oven Cmax

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

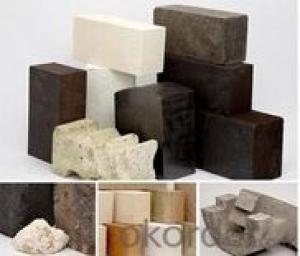

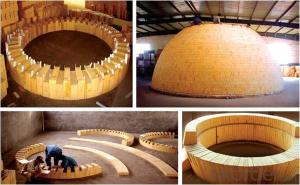

1.Silica brick for coke oven

2.SiO2:95%

3.ISO:9001:2008

4.27 years professional manufacturer

5.MOQ:1MT

Silica refractory brick for Coke oven

Features of Silica refractory brick for Coke oven:

1. high volume density of 2.35 g/cm3

2. high SiO2 content of 95%

3. low iron content of 0.8%

4. long working life of more than 20 years

Applications of Silica refractory brick for Coke oven:

The product is made of phosphorus quartz as main raw materials, and cristobalite as auxiliary material, it has high bulk density, strong thermal conductivity, high temperature stability, the long-term use of creep deformation, long service life (more than twenty years).

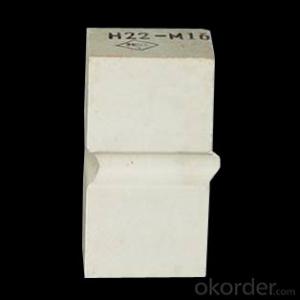

Physical and chemical index of Silica refractory brick for Coke oven

Index | Furnace bottom,furnace wall | Other parts |

SiO2 % ≥ | 95 | 95 |

0.2MPa Refractoriness under load °C ≥ | 1650 | 1650 |

Linear change on reheating 1450°C×2h % | 0~+2 | 0~+2 |

Apparent porosity % ≤ | 22 | 24 |

CCS MPa ≥ | 30 | 24 |

True desity g/cm3 ≤ | 2.34 | 2.35 |

Rate of thermal expansion (1000°C) % ≤ | 1.28 | 1.3 |

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on. The properties and process of silica crystal with SiO2 transformation is closely related, therefore, the proportion of it is one of the important quality indexes of silica brick. General requirements below 2.38, high quality silica brick should be less than 2.35. The true density is small, reflecting a large number of scale quartz and square quartz in the brick, the residual quartz is small, so the residual line expansion is small, and the strength is decreased in useThe raw materials for the manufacture of silica brick. The higher the SiO2 content of silica raw material, the higher the refractoriness. The most harmful impurities are Al2O3, K2O, Na2O and so on. They seriously reduce the refractoriness of refractory products. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer (e.g. millscale, lime) and binder (such as molasses, sulfite pulp waste liquid), after mixing, molding, drying, sintering and other processes in the system.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Can iron oxide be used as refractory material?

- Is widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Can not use it two brick

- The softening temperature is up to 1640~1670 DEG C, and the volume is stable at high temperature for a long time.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick for Coke Oven Cmax

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords