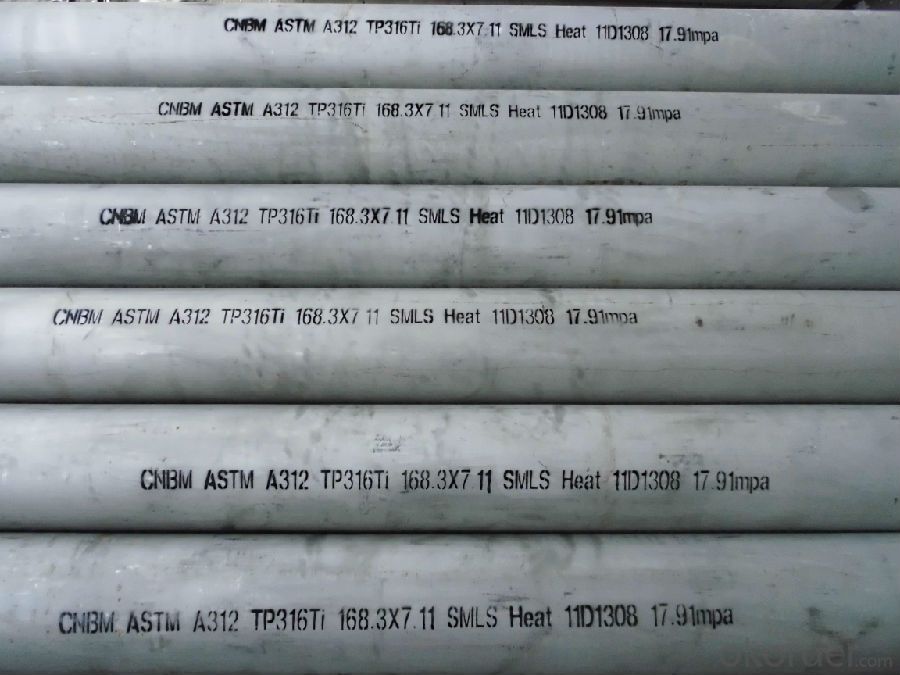

Seamless tube316Ti 10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: How are stainless steel pipes made?

- Stainless steel pipes are typically made through a process called seamless pipe manufacturing. This involves heating a solid stainless steel billet and piercing it with a mandrel to create a hollow tube. The tube is then elongated and rolled to the desired size and thickness using a series of rollers. Finally, the pipe is heat treated, inspected, and cut to the required length before being made available for various industrial applications.

- Q: What is the difference between seamless and HFW stainless steel pipes?

- Seamless and HFW (High Frequency Welded) stainless steel pipes differ in their manufacturing process and the presence of a welded seam. Seamless stainless steel pipes are produced by piercing a solid billet or ingot and then rolling it into a cylindrical shape. This process eliminates the need for any welding, resulting in a pipe without any seams or joints. The absence of a welded seam enhances the overall strength and integrity of the pipe, making it ideal for high-pressure applications. On the other hand, HFW stainless steel pipes are created by using high-frequency electric resistance welding. In this process, a flat strip of stainless steel is passed through a series of rollers and then welded longitudinally using a high-frequency current. The welded seam is then heat-treated to ensure the same corrosion resistance as the base material. HFW pipes are generally more cost-effective compared to seamless pipes, making them a popular choice for various applications. While both seamless and HFW stainless steel pipes offer excellent corrosion resistance and durability, seamless pipes are often preferred in critical applications where high strength and reliability are crucial. The absence of a welded seam minimizes the risk of leakage and failure, making them suitable for industries such as oil and gas, petrochemical, and nuclear power. HFW stainless steel pipes, on the other hand, are more commonly used in less demanding applications such as water supply, plumbing, and construction. They provide a cost-effective solution without compromising the overall performance and corrosion resistance. In summary, the main difference between seamless and HFW stainless steel pipes lies in their manufacturing process and the presence of a welded seam. Seamless pipes are produced without any welding, offering superior strength and reliability for critical applications. HFW pipes, on the other hand, are manufactured through high-frequency electric resistance welding and are more cost-effective, making them suitable for less demanding applications.

- Q: How much is one ton of stainless steel pipe?

- First of all, to determine the use of your stainless steel pipe, and now mainly with 304 stainless steel and 316L stainless steel,304 moderate price, good rust resistance, suitable for daily home decoration.

- Q: What are the common industry standards for stainless steel pipes?

- The common industry standards for stainless steel pipes include ASTM A312/A312M for seamless and welded pipes, ASTM A269 for seamless and welded tubes, and ASME B36.19M for stainless steel pipe dimensions. These standards ensure the quality, dimensions, and performance of stainless steel pipes in various applications.

- Q: Are stainless steel pipes suitable for swimming pool installations?

- Indeed, swimming pool installations can benefit from the use of stainless steel pipes. This material possesses exceptional durability and resistance to corrosion, rendering it a perfect selection for pools that are consistently exposed to water and chemicals. It is not prone to rust or corrosion, resulting in a lengthy lifespan and minimal upkeep. Furthermore, stainless steel pipes boast a sleek surface, mitigating the likelihood of algae growth and blockages. Moreover, they exhibit the capability to endure high pressure and temperature fluctuations, thus accommodating diverse pool systems. In summary, stainless steel pipes guarantee dependability, longevity, and efficiency, making them an apt choice for swimming pool installations.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- The steel tube is a hollow steel strip, used as pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: What is the difference between 17-4PH and 15-5PH stainless steel pipes?

- The main difference between 17-4PH and 15-5PH stainless steel pipes lies in their chemical compositions and mechanical properties. 17-4PH stainless steel contains about 17% chromium, 4% nickel, and 4% copper. It also includes small amounts of molybdenum and niobium. This composition gives it excellent corrosion resistance, high strength, and good toughness. It is commonly used in applications that require high strength, such as aerospace components, oil and gas equipment, and marine applications. On the other hand, 15-5PH stainless steel contains about 15% chromium, 5% nickel, and 3% copper. It also includes small amounts of molybdenum and niobium. This composition provides good corrosion resistance, high strength, and excellent toughness. It is often used in applications that require a combination of strength and corrosion resistance, such as valves, pumps, and shafts. In summary, while both 17-4PH and 15-5PH stainless steel pipes have similar corrosion resistance and high strength, their specific compositions and properties may make them more suitable for different applications.

- Q: Can stainless steel pipes be fabricated?

- Yes, stainless steel pipes can be fabricated. Stainless steel is a versatile material that can be easily manipulated and fabricated into various shapes and sizes. Fabrication processes such as cutting, bending, welding, and threading can be used to shape stainless steel pipes according to specific requirements. These pipes can be fabricated for use in various industries, including construction, automotive, oil and gas, and plumbing, among others. Stainless steel's corrosion resistance and durability make it an ideal choice for fabricating pipes that need to withstand harsh environmental conditions.

- Q: What is the difference between 347 and 321 stainless steel pipes?

- The main difference between 347 and 321 stainless steel pipes lies in their composition and intended use. 347 stainless steel contains a higher amount of niobium, which enhances its resistance to intergranular corrosion, making it suitable for high-temperature applications. On the other hand, 321 stainless steel has titanium as a stabilizing element, providing improved resistance against sensitization during welding.

- Q: What are the different finishes available for stainless steel pipes?

- There are several different finishes available for stainless steel pipes, including brushed, polished, satin, and mill finishes. These finishes can vary in appearance and texture, allowing individuals to choose the one that best suits their desired aesthetic and functional needs.

Send your message to us

Seamless tube316Ti 10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches