Seamless Steel Pipe ASTM A106/A53/API5L Gr.B Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell.

As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Features :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Specification:

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | He Bei, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

FAQ of Seamless Pipe ASTM A106/53:

①Quality

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②Price

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Why us?

▲ CNBM is a state owned enterprise, which background ensures it of funds support and preferential policies

provide by ministry of commerce.

▲ CNBM enjoys a sound reputation both at home and aboard. The company stands a first-rate credit status

and has gained the access to preferential loans through a lot of international banking organizations.

▲ The company is renowned of it manufacturing capabilities and overall sourcing abilities. It has a long

track proven record of strategic cooperation with leading players in steel industry.

▲ Brand name “CMAX” commit to the best quality products and high cost effectiveness which ensures your

company a booming development & success.

Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

Looking forward to doing the corporation with you

Any question, kindly feel free to contact us !

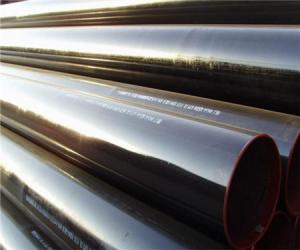

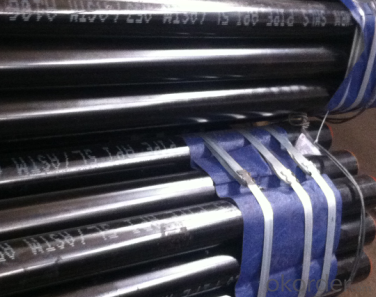

CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Images:

- Q: Can steel pipes be used for stadium construction?

- Yes, steel pipes can be used for stadium construction. Steel pipes are commonly used in stadium construction due to their strength, durability, and ability to withstand heavy loads. They can be utilized for various purposes such as supporting the stadium structure, creating frames for roof structures, and facilitating the installation of plumbing and electrical systems. Additionally, steel pipes can be easily fabricated, allowing for efficient construction and customization according to the specific requirements of the stadium design.

- Q: How do steel pipes compare to other materials like PVC or copper pipes?

- Steel pipes have numerous advantages over materials such as PVC or copper pipes. Firstly, their strength and durability make them ideal for high-pressure applications. They can withstand extreme temperatures and resist corrosion, making them suitable for both indoor and outdoor use. In contrast, PVC pipes are weaker and more prone to cracking and breaking under pressure or in extreme temperatures. Although copper pipes are durable, they can be susceptible to corrosion and may require additional protective coatings. Secondly, steel pipes have a longer lifespan compared to PVC or copper pipes. They are renowned for their longevity and can last for several decades without needing replacement. PVC pipes, although relatively inexpensive, have a shorter lifespan and may require more frequent replacement. Similarly, copper pipes can corrode over time and may need maintenance or replacement. Another advantage of steel pipes is their ability to handle a wide range of fluids and substances. They are commonly used in industrial applications where chemicals or corrosive materials may be present. PVC pipes, on the other hand, may not be suitable for handling certain chemicals or substances as they can react and cause damage to the pipe. Copper pipes, while generally safe for carrying water, may not be ideal for conveying certain chemicals or fluids. Additionally, steel pipes possess excellent fire resistance properties. In the event of a fire, they can withstand high temperatures and maintain their structural integrity, ensuring the safety and protection of the surrounding area. PVC pipes, however, can melt or deform under high heat, potentially causing structural damage. Although copper pipes are less prone to melting, they can still be affected by extreme heat and lose their strength. Nevertheless, steel pipes do have a few drawbacks. They tend to be heavier and more challenging to install compared to PVC or copper pipes. Additionally, they can be more expensive upfront, especially when compared to PVC pipes. However, considering their durability and longevity, steel pipes may offer better value in the long run. In conclusion, steel pipes provide numerous advantages over materials like PVC or copper pipes. They are strong, durable, resistant to corrosion, and have a longer lifespan. They can handle high-pressure applications and a wide range of fluids, making them suitable for various industrial and commercial uses. Although they may be more expensive and difficult to install, the benefits of steel pipes make them a reliable and cost-effective choice for many applications.

- Q: Can steel pipes be used for sewage treatment plants?

- Yes, steel pipes can be used for sewage treatment plants. Steel pipes are commonly used in sewage treatment plants due to their durability, strength, and resistance to corrosion. They can efficiently transport wastewater and withstand the harsh chemical environment found in sewage treatment facilities.

- Q: How are steel pipes used in the construction of pipelines?

- Steel pipes are commonly used in the construction of pipelines due to their high durability, strength, and ability to withstand high pressure. These pipes are used to transport various fluids, such as oil, gas, and water, over long distances. They are welded together and laid underground or submerged to create a reliable and efficient transportation system for these resources.

- Q: How do you join two steel pipes together without welding?

- One common method to join two steel pipes together without welding is by using mechanical fittings or connectors. These fittings are designed to connect pipes securely without the need for welding. Here are a few options you can consider: 1. Threaded Fittings: Threaded fittings have male and female threads that enable you to screw them together. To join the pipes, you will need to cut the ends of the pipes to create male and female threads. Apply thread sealant to ensure a tight and leak-free connection. 2. Compression Fittings: Compression fittings consist of a nut, a compression ring, and a compression seat. These fittings are designed to create a tight seal by compressing the ring against the seat. Simply slide the compression ring and nut onto the pipe ends, and use a wrench to tighten the nut until it forms a secure connection. 3. Flange Connections: Flange connections involve using flanges, which are flat plates with bolt holes, to join the pipes. The flanges are bolted together using gaskets to create a tight seal. This method is commonly used for larger diameter pipes or in situations where frequent disassembly may be required. 4. Grooved Couplings: Grooved couplings utilize a mechanical coupling housing with two grooved ends that fit over the pipe ends. The coupling is then secured using bolts or screws, which tighten the housing around the pipe ends, creating a secure connection. This method is often used in plumbing and fire protection systems. Before deciding on a method, it is crucial to consider the specific requirements of your application, such as the pipe diameter, pressure, and temperature. Additionally, ensure that the chosen method complies with relevant industry standards and regulations to ensure a safe and reliable connection.

- Q: How do steel pipes perform in extreme weather conditions?

- Steel pipes generally perform well in extreme weather conditions. They have high strength and durability, making them resistant to harsh weather elements such as extreme temperatures, heavy rainfall, and strong winds. The material's resistance to corrosion and rust also ensures that the pipes can withstand long-term exposure to moisture and other environmental factors. However, it is important to note that proper maintenance and protective coatings can further enhance their performance and lifespan in extreme weather conditions.

- Q: Can steel pipes be used for gas lines?

- Yes, steel pipes can be used for gas lines. Steel pipes are commonly used for gas lines due to their durability, strength, and resistance to extreme temperatures. They are able to withstand high pressure and are typically coated with corrosion-resistant materials to ensure the safety and longevity of the gas line system.

- Q: What are the advantages of using steel pipes?

- There are several advantages of using steel pipes. Firstly, steel pipes are extremely durable and have a long lifespan, making them a cost-effective choice for various applications. Secondly, steel pipes have high resistance to corrosion, making them suitable for use in harsh environments and underground applications. Thirdly, steel pipes have high strength and can withstand heavy loads, making them ideal for transporting fluids and gases under high pressure. Additionally, steel pipes are versatile and can be easily welded, threaded, or bent to fit specific requirements. Lastly, steel pipes are recyclable, making them an environmentally friendly choice.

- Q: DN150 welded steel tubes one meter multiple

- The theoretical weight table of welded steel pipe (Kg) can be checked, and the outer diameter and wall thickness can be measured according to the formula.For example: DN150 welded steel pipe, diameter 165mm, thickness 4.5mm, weight kg per meter.Welded steel pipe theoretical weight (Kg/m) = (165-4.5) * 4.5 * 0.02466=17.81Kg

- Q: What are the different types of steel pipes?

- There are several different types of steel pipes, including seamless steel pipes, welded steel pipes, galvanized steel pipes, and stainless steel pipes.

Send your message to us

Seamless Steel Pipe ASTM A106/A53/API5L Gr.B Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords