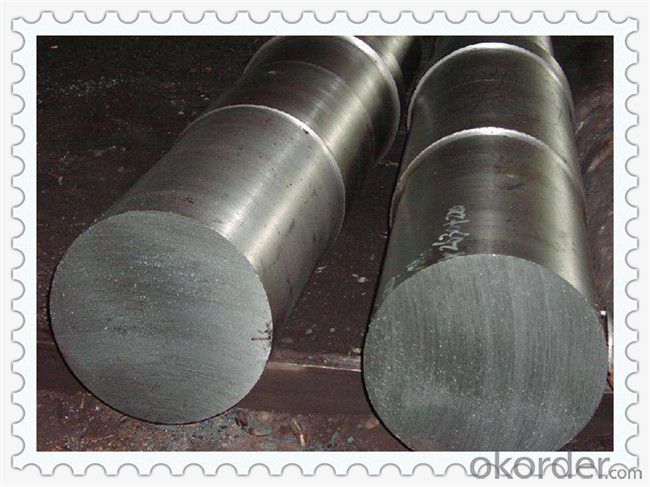

SCM440 SCM415 SAE4140 Steel Round Bar /AISI 4140 Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SCM440 SCM415 SAE4140 Steel Round Bar /AISI 4140 Steels

1. Dia:12mm-300mm

2. Standard Performed: ASTM A29/A29M-04

3. Equal Standard:

America Standard: AISI4140

International Standard: 42CrMo4

Japan Standard: SCM440

Germany Standard: 42CrMo4

4. Chemical composition:

Grade | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Al |

AISI4140 | 0.38 0.41 | 0.15 0.35 | 0.85 1.00 | Max 0.015 | Max 0.040 | Max 0.25 | 0.80 1.10 | 0.15 0.25 | Max 0.35 | 0.012 0.030 |

5. Grade: ASTM A29 4140 42CrMo SCM440

Hardness:217HB

Tensile strength:1080(110)MPA

Yield strength: 930(95)MPA

Elogation: 12%

Reduction of area: 45%

AKV(impact value): 63J

- Q: Can steel round bars be used in the manufacturing of cylinders?

- Yes, steel round bars can be used in the manufacturing of cylinders. Steel round bars are often used as raw material for manufacturing cylinders due to their high strength, durability, and ability to withstand high pressure and temperature conditions.

- Q: Are steel round bars used in the aerospace industry?

- Yes, steel round bars are commonly used in the aerospace industry for various applications such as structural components, landing gears, and engine parts. The high strength, durability, and excellent mechanical properties of steel make it an ideal material choice for aircraft manufacturing.

- Q: What are the advantages of using maraging steel round bars?

- There are several advantages of using maraging steel round bars in various applications. 1. High strength: Maraging steel round bars have an exceptionally high strength-to-weight ratio, making them ideal for applications where strength is crucial. These bars can withstand high stress and load-bearing conditions without deformation or failure, ensuring structural integrity. 2. Superior toughness: Maraging steel round bars exhibit excellent toughness, which means they can absorb a significant amount of energy before fracturing. This property makes them highly resistant to cracking or breaking, even under extreme conditions, enhancing their durability and reliability. 3. Corrosion resistance: Maraging steel round bars are known for their exceptional corrosion resistance. They are less susceptible to rust and oxidation compared to other types of steel, making them suitable for applications in harsh environments or where exposure to moisture or chemicals is a concern. This corrosion resistance helps prolong the lifespan of the bars and reduces maintenance costs. 4. Machinability: Maraging steel round bars are relatively easy to machine, despite their high strength and hardness. They can be readily shaped, drilled, and cut into various forms and sizes, allowing for versatile applications across different industries. This ease of machining saves time and effort during the manufacturing process. 5. Heat treatability: Maraging steel round bars have excellent heat treatability, meaning they can be hardened and tempered to further improve their mechanical properties. This flexibility in heat treatment allows for customization to meet specific project requirements, such as achieving desired hardness levels or enhancing specific characteristics like wear resistance or toughness. 6. Aerospace and defense applications: Maraging steel round bars are widely used in aerospace and defense industries due to their exceptional strength, toughness, and corrosion resistance. They are commonly employed in the manufacturing of critical components like landing gear, missile casings, and aircraft structures, where reliability and performance are of utmost importance. Overall, the advantages of using maraging steel round bars include their high strength, superior toughness, corrosion resistance, machinability, heat treatability, and suitability for aerospace and defense applications. These properties make them a preferred choice for various demanding industries and ensure optimal performance and longevity in critical applications.

- Q: Can steel round bars be heat treated to enhance their properties?

- Steel round bars can undergo heat treatment to improve their properties. This process involves controlled heating and cooling to modify the microstructure of the steel, ultimately enhancing its mechanical properties like strength, hardness, toughness, and ductility. Various heat treatment methods can be employed based on the desired outcome. One commonly used method is quenching and tempering. This involves heating the steel to high temperatures, forming a uniform austenitic structure, then rapidly cooling it in oil or water to transform the austenite into a stronger structure called martensite. However, martensite can be brittle, so the steel is subsequently tempered by reheating it at lower temperatures to reduce brittleness while maintaining the desired hardness. Another method is annealing, where the steel is heated to a specific temperature and slowly cooled to relieve internal stresses and enhance ductility. This process also refines the grain structure of the steel, improving machinability and formability. Furthermore, there are other heat treatment methods like normalizing, stress relieving, and case hardening, each tailored to enhance specific properties of steel round bars. Overall, heat treatment is a versatile and effective technique for enhancing the properties of steel round bars, enabling them to meet specific requirements in industries such as manufacturing, construction, automotive, and aerospace.

- Q: Can steel round bars be used for making bicycle frames?

- Yes, steel round bars can be used for making bicycle frames. Steel is a commonly used material in bicycle frame construction due to its strength, durability, and affordability. Steel round bars can be easily shaped and welded to create the desired frame design, making them a suitable choice for bicycle manufacturing.

- Q: What is the tolerance for length in steel round bars?

- The tolerance for length in steel round bars can vary based on specific manufacturing standards and requirements. Typically, the tolerance is defined as the maximum allowable deviation from the desired length and can be expressed as a percentage or specific measurement in millimeters or inches. Various international standards organizations, such as ASTM or ISO, may have their own guidelines for steel round bar tolerances. These standards ensure consistent and reliable measurements across the industry. In practice, tolerances for steel round bar length can range from tight tolerances of a few millimeters for precision applications to looser tolerances of several centimeters for general-purpose use. It is important to consider that the tolerance may also depend on the size and diameter of the bar. Smaller diameter bars may have tighter tolerances due to the challenges in manufacturing and accurately measuring longer lengths. Ultimately, the specific tolerance for steel round bar length should be determined based on the intended application and relevant industry standards or customer specifications.

- Q: Can steel round bars be used in high-temperature environments?

- Yes, steel round bars can be used in high-temperature environments. However, the specific type of steel and its composition need to be carefully chosen to ensure it has the necessary heat resistance properties, such as high melting point and good strength retention at elevated temperatures.

- Q: What is the minimum diameter available for steel round bars?

- The minimum diameter available for steel round bars can vary depending on the specific manufacturing and supplier capabilities. However, in general, steel round bars can be found in a wide range of diameters starting from as small as 1/8 inch (3.175 mm) and going up to several inches or even larger. It is best to consult with steel suppliers or manufacturers to determine the exact minimum diameter available for steel round bars based on your specific requirements.

- Q: What are the advantages of using spring steel round bars?

- There are several advantages of using spring steel round bars: 1. High strength: Spring steel round bars are known for their exceptional strength. They are designed to withstand high levels of stress and strain, making them ideal for applications that require strong and durable materials. 2. Flexibility: Spring steel round bars have excellent flexibility, allowing them to be easily shaped, bent, or formed without losing their strength. This flexibility makes them suitable for various manufacturing processes and applications. 3. Superior elasticity: Spring steel round bars possess excellent elasticity, enabling them to return to their original shape after being subjected to deformation or stress. This elasticity is crucial in applications where materials need to absorb shocks or vibrations. 4. Resistance to fatigue: Spring steel round bars are highly resistant to fatigue and can withstand repeated cycles of loading and unloading without losing their mechanical properties. This resistance to fatigue ensures their reliability and longevity, making them suitable for demanding applications. 5. Excellent toughness: Spring steel round bars exhibit exceptional toughness, which means they can withstand sudden impact or heavy loads without breaking or fracturing. This characteristic makes them suitable for applications that require materials to withstand harsh environments or heavy-duty operations. 6. Corrosion resistance: Many spring steel round bars are made from corrosion-resistant alloys, providing protection against rust and other forms of corrosion. This corrosion resistance makes them suitable for applications where exposure to moisture or corrosive substances is expected. 7. Cost-effective: Spring steel round bars offer a cost-effective solution compared to other types of steel or materials. Their durability and longevity reduce the need for frequent replacements, ultimately saving costs in the long run. In summary, the advantages of using spring steel round bars include high strength, flexibility, superior elasticity, resistance to fatigue, excellent toughness, corrosion resistance, and cost-effectiveness. These properties make them a preferred choice in various industries, including automotive, construction, manufacturing, and aerospace.

- Q: Can steel round bars be bent or shaped?

- Certainly! Steel round bars have the capability to undergo bending and shaping. Steel, being a highly malleable material, can be formed into desired shapes through different processes. Techniques such as hot bending, cold bending, or induction bending can be employed to bend the steel. By applying force to the steel bar, it can be deformed and molded into the desired shape. Moreover, machining processes like turning, drilling, milling, or grinding can also be utilized to shape steel round bars. These processes enable the creation of various profiles, including cylindrical, square, or hexagonal shapes, among others. In summary, steel round bars provide great flexibility for bending and shaping, allowing for their versatile use in a wide range of applications.

Send your message to us

SCM440 SCM415 SAE4140 Steel Round Bar /AISI 4140 Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords