Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

Products Details

1. Chemical Composition and Mechanical Properties(In Quenched & Tempered State)

Material | 4140 | ||

Chemical Composition | Mechanical Properties(In Quenched & Tempered State) | ||

C | 0.38-0.45 | Tensile strength(MPA) | ≥1080 |

Si | 0.17-0.37 | Yield strength (MPA) | ≥930 |

Mn | 0.50-0.80 | Elongation(δ5/%) | 12 |

Cr | 0.90-1.20 | Reduction in Area (ψ/%) | 45 |

Mo | 0.15-0.25 | Impact (J) | 63 |

P | ≤0.035 |

Hardness |

≤217HB |

S | ≤0.035 | ||

Cu | ≤0.30 | ||

Ni | ≤0.30 | ||

2. Product Application Areas

Our products have been used in all kinds of areas, such as aviation,aerospace,navigation,nuclear energy,chemical industry,electronic information,achine manufacture, petrochemical, automotive,instrument and meter, Communication ,transportation, and medical instruments, etc.

3. Similar steel grade & equivalent steel materials

USA | Japanese | Gemany | British | France | International | Chinese |

ASTM&AISI&SAE | JIS | EN DIN | EN BS | EN NF | ISO | GB |

4140 | SCM440 | 42CrMo4 1.7225 | 42CrMo4 1.7225 | 42CrMo4 1.7225 | ------ | 42CrMo |

Product Sales Information

Material | 4140 steel round bar |

Size | Diameter:20mm-1000mm Length:500mm-6000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled,cold drawn,forged |

Surface require | Black,grinding,bright,polish |

Heat treatment | Quenched,Tempered,annealed |

Packing | seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | In 10-50 days |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

MOQ | 1 Ton |

Company Main Products

Alloy Steel | 4140, 4142, 42CrMo4, 1.7225, SCM440, 4130, SCM430, 25CrMo4, 1.7218, 34CrNiMo6, 1.6582, 4340, SNCM439, 36CrNiMo4, 1.6511, SACN645, 1340, SMn438, SNC236, |

Tool Steel | H13, 1.2344, SKD61, D2, SKD11, 1.2379, 1.2510, 01, SKS3, 95MnWCr5, D3, SKD1, 1.2419, SKS31, H21, SKD5, 1.2581, P20, 35CrMo7, 1.2738, 1.2316, M2 |

Bearing Steel | GCr15, 52100, SUJ1, SUJ2, 100Cr6, 1.2067, 55C, 8620, 4320, 9310, 440C, M50 |

Spring Steel | 9260, SUP6, SUP7, 1.7108, 54SiCr6, 1.7102, 5155, SUP9, 1.7176, 5160, 1.7177, 6150, SUP10, 51CrV4, 1.8159 |

Stainless Steel | 321, sus321, 1.4541, 304, SUS304, 1.4301, 410, SUS410, 1.4006, 420, 1.4021, 1.4028, 434, 1.4113, 316L, SUS316L, 1.4435, 630, 1.4542, 431, 1.4057, |

Products Show

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

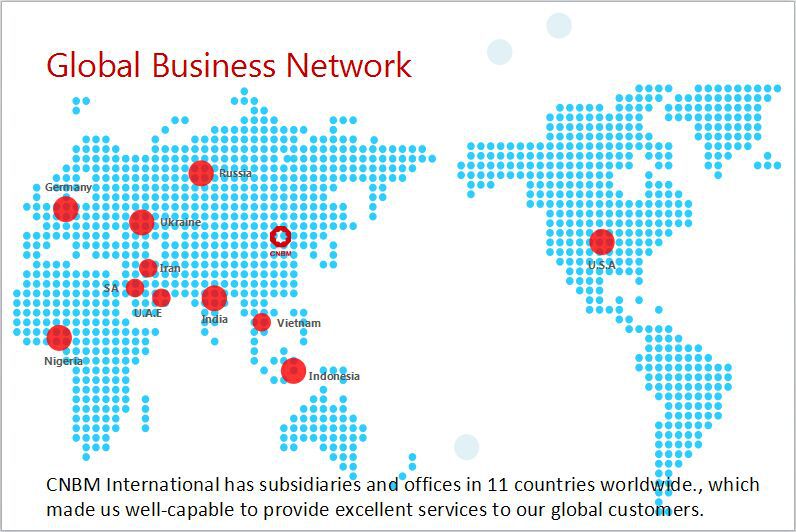

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the different surface defects that can occur in steel round bars?

- Steel round bars can experience various surface defects, which can be categorized based on their appearance and severity. Some common defects include: 1. Scale: During the manufacturing process, a thin layer of oxide, known as scale, can form on the steel's surface. It appears rough and flaky and can be easily removed mechanically. 2. Pits: Small depressions or craters, caused by corrosion or mechanical damage, can occur on the steel's surface. Pits weaken the steel's structural integrity and may require repair or replacement. 3. Scratches: Shallow grooves or cuts, resulting from handling, transportation, or machining, can be found on the steel's surface. While minor scratches may not impact performance, deep scratches can cause stress concentration and potential failure. 4. Roll marks: Raised or depressed lines or patterns, formed during the rolling process, can be seen on the steel's surface. Uneven pressure distribution between rolls causes these marks, affecting dimensional accuracy and surface quality. 5. Laminations: Thin layers or bands of non-metallic inclusions parallel to the steel's surface, caused by inadequate refining or improper casting techniques, are known as laminations. They reduce strength and toughness, requiring further processing or rejection. 6. Decarburization: The loss of carbon content on the steel's surface, occurring during heating, annealing, or hot working, is referred to as decarburization. It decreases hardness and strength, potentially leading to premature failure. 7. Surface cracks: Visible cracks on the steel's surface, caused by excessive cooling rates, improper heat treatment, or mechanical stress, are surface cracks. They compromise structural integrity and may necessitate repairs or rejection. These examples cover just a few of the possible surface defects in steel round bars. It is crucial to inspect and address these defects to ensure the steel's quality and performance in various applications.

- Q: Can steel round bars be used for making gears?

- Certainly! Gears can indeed be made using steel round bars. The reason for their widespread use in gear manufacturing lies in their outstanding strength, longevity, and ability to withstand damage. These bars can be processed, subjected to heat treatment, and molded into different types of gears, including spur gears, helical gears, and bevel gears. Steel round bars provide exceptional accuracy and dependability, making them ideal for applications demanding durable and high-performing gears, like automotive transmissions, industrial machinery, and power transmission systems.

- Q: How strong are steel round bars compared to other materials?

- Steel round bars are known for their exceptional strength and durability, making them one of the strongest materials available. Compared to other materials such as aluminum, brass, and wood, steel round bars have a significantly higher tensile strength, which refers to the amount of pulling force a material can withstand without breaking. Steel round bars can also handle higher compressive loads, making them ideal for applications where heavy loads or pressure is involved. In addition to their high strength, steel round bars also exhibit excellent ductility, which means they can be easily shaped or bent without breaking. This characteristic makes steel round bars versatile and widely used in various industries such as construction, automotive, manufacturing, and aerospace. While other materials may have their own unique properties and applications, steel round bars remain a top choice when it comes to strength and reliability. Their ability to withstand high loads, resist deformation, and maintain structural integrity make them a popular choice for structural components, shafts, axles, and many other demanding applications.

- Q: What is the difference between a peeled and a polished steel round bar?

- A peeled steel round bar and a polished steel round bar are two different types of steel bars with distinct characteristics and applications. A peeled steel round bar is a steel bar that has undergone a peeling process. During this process, the outer surface of the bar is removed, resulting in a smooth and clean finish. The peeling process removes any imperfections or scale on the surface of the bar, improving its appearance and quality. This makes peeled steel round bars ideal for applications where a smooth surface is required, such as in the manufacturing of precision components, shafts, or spindles. The process of peeling also enhances the mechanical properties of the bar, improving its strength and toughness. On the other hand, a polished steel round bar is a steel bar that has undergone a polishing process. In this process, the surface of the bar is polished using abrasive materials to create a shiny and reflective finish. The polishing process removes any surface imperfections, scratches, or dullness, resulting in a visually appealing and aesthetically pleasing appearance. Polished steel round bars are often used in decorative applications, architectural designs, or in industries where a visually attractive finish is desired, such as in furniture manufacturing or automotive accessories. In summary, the main difference between a peeled and a polished steel round bar is the process they undergo and the intended applications. A peeled steel round bar is processed to remove imperfections and improve mechanical properties, making it suitable for precision components, while a polished steel round bar is processed to create a shiny and reflective surface, making it ideal for decorative or visually appealing applications.

- Q: The 8 thread can replace the beam stirrups by steel

- That's fine, but it's not necessary. It's more expensive. Of course, there's no substitute for steel bars on the site.

- Q: What is the difference between a forged and a ground steel round bar?

- The manufacturing processes and resulting characteristics of a forged steel round bar and a ground steel round bar differ significantly. To create a forged steel round bar, the steel is subjected to high temperatures and then shaped using mechanical pressure, typically with a hammer or press. This process aligns the grain structure of the steel, enhancing its strength and durability. The forged steel round bars are renowned for their exceptional strength, impact resistance, and overall toughness. They find widespread use in applications that demand high strength, such as heavy machinery, automotive parts, and construction equipment. On the contrary, a ground steel round bar is manufactured using a grinding process. Once the steel is initially shaped, it undergoes precise grinding to achieve the desired dimensions and surface finish. This grinding process eliminates any imperfections or irregularities on the surface, resulting in a smooth and polished appearance. Ground steel round bars are commonly employed in applications that necessitate precise dimensions, like shafts, axles, and precision tools. In conclusion, the primary distinction between a forged steel round bar and a ground steel round bar lies in their manufacturing processes and resultant properties. The forged steel round bar offers superior strength and toughness due to the alignment of its grain structure, making it a suitable choice for heavy-duty applications. Conversely, the ground steel round bar is renowned for its precise dimensions and polished surface finish, rendering it an ideal option for applications that require precision.

- Q: How do steel round bars compare to wood round bars?

- Steel round bars have several advantages over wood round bars. Firstly, steel is much stronger and more durable than wood, making steel round bars a more reliable and long-lasting option. Steel round bars also have higher tensile strength, meaning they can withstand greater force without breaking. Additionally, steel is resistant to moisture, rot, and pests, making it a better choice for outdoor or high-moisture environments. On the other hand, wood round bars may be preferred in certain applications for their natural aesthetic appeal and lower cost. Overall, steel round bars offer superior strength, durability, and resistance to environmental factors compared to wood round bars.

- Q: What is the weight of a steel round bar?

- The weight of a steel round bar can vary depending on its dimensions and the type of steel used. Generally, the weight of a steel round bar can be calculated by multiplying its volume (pi times the square of the radius times the length) by the density of the steel.

- Q: Can steel round bars be used for tooling applications?

- Tooling applications can indeed utilize steel round bars. Steel, being a highly versatile material, possesses exceptional strength, durability, and resistance to wear and tear. By machining, heat treating, and shaping round bars made of steel, one can create a wide range of tools, including punches, dies, drills, and lathe tools. The round shape of these bars facilitates effortless machining and shaping processes. Moreover, the performance of steel round bars in specific tooling applications can be further enhanced through surface treatments or coatings. All in all, due to their outstanding mechanical properties and adaptability, steel round bars find widespread application in tooling.

- Q: What is the maximum length available for steel round bars?

- The maximum length available for steel round bars can vary depending on the supplier and the specific requirements, but typically it can range from 12 to 24 feet.

Send your message to us

Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords