SBS Modified Bitumen Waterproof Membrane 3 MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

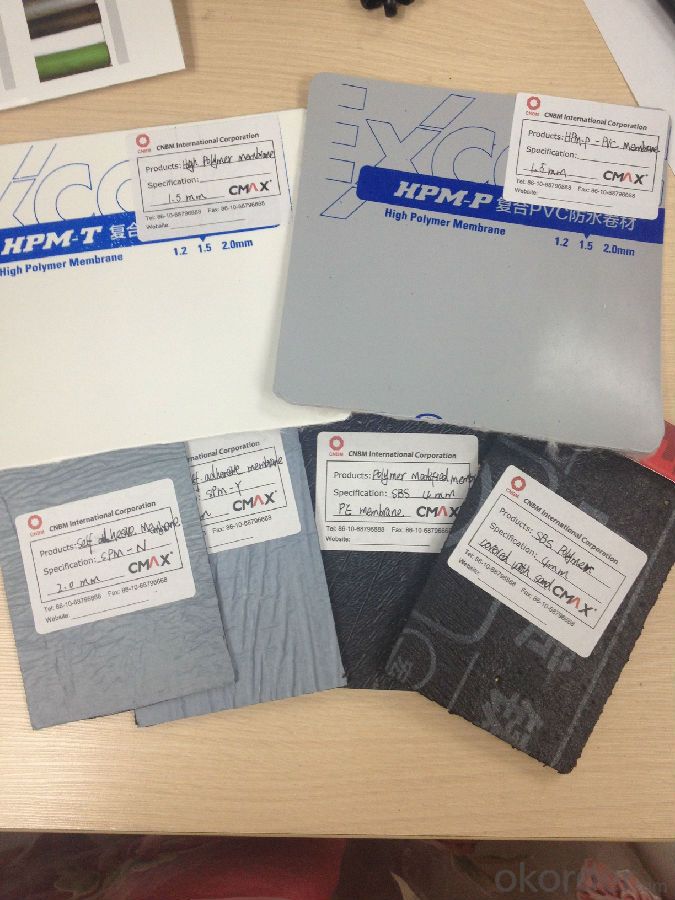

Quick DetailsType:

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details: 10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

No crack

a Only applicable to single mechanical fixed membrane construction way

B Only applicable to mineral surface bitumen waterproof membrane

C Only applicable to hot melt construction of membrane

Features

Good ability of anti-aging, anti-alkali, resistant to high temperature. High tensile strength and enlongation, which adapts to the contraction or crack of the base.

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

3. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

Package

the membrane is launched into the market in rolls 1m wide and 10m long.

Storage Conditions and Service life

Rolls must be vertically stored in roofed-over spaces. If the rolls have to be stored outdoors for a long period of time, then they must be covered with a protective layer in order to protect them against the sunlight. If the rolls are to be stowed without pallets, they they are not stacked one on top of another. In palletised stowage, two rows may be stacked one on top of the other.

Attentions for Construction

·Construction shall not be carried out in rain, snow or over 5 degree wind weather;

There shall be sufficient safety protective facilities in construction site, place firefighting devices according to stipulations.

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

- Q: Can a waterproofing membrane be used on wood surfaces?

- Indeed, wood surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically engineered to form a barricade against water infiltration, effectively safeguarding the surface they are applied on. While their typical usage involves concrete or masonry surfaces, they can also be utilized on wood surfaces to shield them from moisture-induced harm. By employing a waterproofing membrane on wood surfaces, the absorption of water can be curtailed, thus preventing potential issues such as rot, warping, or decay. It is crucial to select a waterproofing membrane that is specifically tailored for wood, as it will furnish the necessary protection while allowing the wood to breathe and maintain its innate characteristics.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Yes, a waterproofing membrane can be used on asphalt surfaces. Waterproofing membranes are often used to protect various surfaces, including asphalt, from water damage. They create a barrier that prevents water from seeping into the asphalt, reducing the risk of cracks, deterioration, and other forms of damage caused by moisture.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Both interior and exterior surfaces can benefit from the use of a waterproofing membrane. These membranes are created with the purpose of safeguarding surfaces against water infiltration and harm. Rubber, asphalt, or thermoplastic materials are commonly utilized to construct these membranes, which form a barrier to prevent moisture from penetrating. Whether applied to interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane is highly effective in averting issues such as leaks, mold, or structural damage caused by water seepage. It is crucial to carefully consider the unique requirements of each surface and select an appropriate waterproofing membrane for the intended use.

- Q: Can a waterproofing membrane be used in areas with high water pressure?

- Indeed, areas with high water pressure can benefit from the use of a waterproofing membrane. These membranes are engineered to endure and repel water infiltration, rendering them suitable for locations with elevated water pressure. Typically composed of robust materials like rubber, PVC, or bitumen, these membranes possess exceptional durability and superior waterproofing properties. Furthermore, their strength and resistance to water pressure can be augmented by reinforcing them with additional layers or fabrics. However, to guarantee their effectiveness in high water pressure scenarios, it is crucial to properly install the waterproofing membrane and ensure it meets the area's specific requirements. Seeking professional advice and adhering to the manufacturer's guidelines are highly advised to ensure optimal performance in these conditions.

- Q: Can a waterproofing membrane be used on plaster surfaces?

- Plaster surfaces can benefit from the use of a waterproofing membrane. Due to its porous nature, plaster readily absorbs water, which can lead to damage caused by moisture. By applying a waterproofing membrane to plaster surfaces, a barrier is created to prevent water infiltration. This protective measure safeguards against problems like mold, mildew, and deterioration caused by moisture. Before applying the membrane, it is crucial to ensure the plaster surface is clean, dry, and devoid of loose or flaking material. It is also important to follow proper surface preparation and application techniques to guarantee the effectiveness and durability of the waterproofing system.

- Q: How much does a waterproofing membrane cost?

- The cost of a waterproofing membrane can vary depending on factors such as the type of membrane, the size of the area to be waterproofed, and the brand. On average, you can expect to spend anywhere from $1 to $5 per square foot for the material and installation.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Yes, a waterproofing membrane can be used on stadium seating areas to provide protection against water damage and ensure the longevity of the seating structure.

- Q: Can a waterproofing membrane be used in residential construction?

- Yes, a waterproofing membrane can be used in residential construction. Waterproofing membranes are commonly used in various areas of a residential property, such as roofs, basements, bathrooms, and foundations. These membranes are designed to prevent water penetration and protect the structure from moisture-related damages. By installing a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks, which can lead to mold growth, structural deterioration, and other costly issues. There are various types of waterproofing membranes available in the market, including sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can help determine the most appropriate waterproofing membrane for a particular residential construction project.

- Q: Can a waterproofing membrane be used for stadiums and sports arenas?

- Yes, a waterproofing membrane can be used for stadiums and sports arenas. It is a commonly used solution to protect these structures from water damage and leakage. The membrane helps in preventing water penetration and effectively keeps the interior areas dry and safe.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

Send your message to us

SBS Modified Bitumen Waterproof Membrane 3 MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords