Sand Casting Ductile Iron Manhole Cover EN124

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

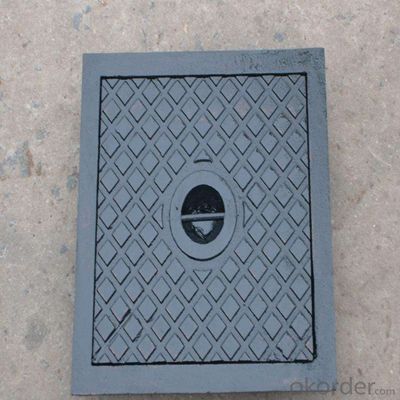

product name: ductile iron manhole cover

1. material: cast iron, ductile iron, malleable iron

2. duty: EN124 A15 B125 C250 D400 E600 F900

3. color: black green gray and etc.

4. design: we can provide OEM service, according your design to do moulds, surface and logo.

5. application: expressway, sidewalk, park, garden, municipal pipeline, telecommunication, water and electrical power projects.

Pictures

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

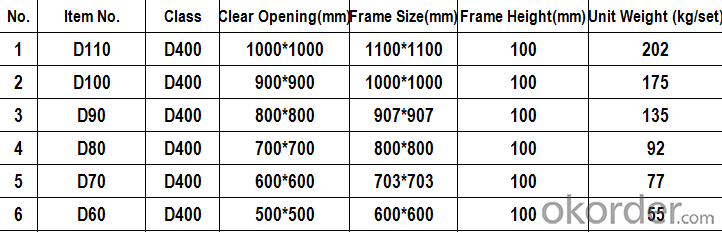

Specification

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

Company Information

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

Send your message to us

Sand Casting Ductile Iron Manhole Cover EN124

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords