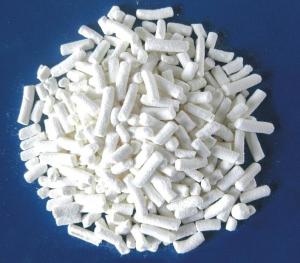

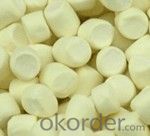

RUBBER VULCANIZING ACCELERATOR ZDBC (BZ)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

RUBBER VULCANIZING ACCELERATOR ZDBC (BZ)

Chemical Name: Zinc dibutyl dithiocarbamate

Molecular Formula: C18H36N2S4Zn

Molecular Weight: 474.1

CAS NO. : 136-23-2

Executive standard:Q/ZYCH6-2003

Specification:

| Index |

Acceptable end-product | |

Appearance | white powder |

Initial M.P, oC ≥ | 180.0 |

Loss on drying, % ≤ | 0.50 |

Ash, % ≤ | 10-12 |

Residues on 150μm sieve,% ≤ | 0.50 |

Properties: White powder. The density is 1.24. Soluble in carbon sulfide. benzene, chloroform, insoluble in water. Good storage stability.

Application: Used for primary or secondary ultra-accelerator in NR. IR, BR, SBR, NBR, HR. EPDM, and their latexes. Similar in property to PZ and EZ. less accelerating effects than PZ and EZ to dry rubber. Effectively used in both natural and synthetic latexes for faster curing at normal (low) temperature than with PZ and EZ, and less scorching and blooming

Packaging: 25kg plastic woven bag, paper with plastic film bag, Kraft paper bag, or jumbo bag.

Storage: The product should be stored in the dry and cooling place with good ventilation, avoiding exposure of the packaged product to direct sunlight. The validity is 2year.

Note: The product could be ultra fine powder based on customer accurate requirement.

- Q: Co and No form a chemical equation for Co2 and No2 under the action of a catalyst

- Write the catalyst on the horizontal line, where NO is the oxidant and CO is the reducing agent

- Q: How do I write about the ion equation?

- 4NH3 + 5O2 == 4NO + 6H2O

- Q: What is the microcosmic principle of the catalytic reaction in the chemical reaction?

- It is actually directly involved in the reaction, but, after the reaction, it has become a product out, the equivalent of no response

- Q: How does the chemical equation calculate the quality of the catalyst?

- So the reactant mass is equal to the quality of the product, with the quality of conservation

- Q: The role of catalyst in chemical reactions

- The role of the catalyst is to change the reaction required to achieve the activation energy, can reduce the activation energy is called positive catalyst (that is, usually the meaning of the catalyst), to improve the activation energy is negative catalyst

- Q: Brief introduction of enzyme as biocatalyst and general chemical catalyst and its personality

- can only change the rate of chemical reaction, do not change the equilibrium point of the chemical reaction, the enzyme itself does not change before and after the chemical reaction (3) can reduce the chemical reaction of the activation energy The

- Q: Does increasing the amount of catalyst added to, say, a solution of Hydrogen Peroxide, make the rate of reaction go faster. Is the rate of reaction directly proportional to the amount of catalyst added to the solution? Or does the experiment go at the same rate regardless of how much catalyst there is? Thanks would really appreciate some answers. - Sarah

- Catalyst do not participate in the reaction but it speeds up the reaction. If you increase the amount of catalyst from the required amount, it would somehow negates its positive response or it would result in producing another product.

- Q: How to poison the catalyst. What can be done?

- In the reactants or catalyst mixed with a small amount of material, so that the catalyst catalytic capacity of a sharp decline or even loss, this phenomenon is called catalyst poisoning. For example, in the synthesis of ammonia feed gas containing CO, CO2 and H2S, PH3, water vapor and other impurities, can make iron catalyst poisoning; contact with the system of sulfuric acid, if arsenic and selenium oxide (As2O3, SeO2), can make vanadium catalyst Loss of activity. Therefore, it is necessary to purify the feed gas, prevent the poisoning of the catalyst, and also reduce the corrosion of the equipment. The phenomenon of catalyst poisoning is sometimes temporary, the removal of toxicants, the effectiveness of the catalyst can still be restored; sometimes it is permanent, without chemical treatment can not restore catalytic performance.

- Q: put in a way that a freshman in high school can understand please =)

- enzymes are a type of catalyst

Send your message to us

RUBBER VULCANIZING ACCELERATOR ZDBC (BZ)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches