Round Steel 5115 Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Round Steel 5115 Steel Bars

Products Details

1. good mechanical property

2. high temper resistance

3. hardened and tempered steel

4. 12-250mm/200~650mm

| Material standardized according to | 5115 round steel round bar |

| Unfinished products manufactured | Pipes - profiles - squares |

| Properties | Excellent mechanical features - good workability on high-speed automatic machines with easy fragmentation of the shavings made by the tool |

| Typical applications | used for making heavy loading and sectional gear shaft,gear,connecting rod,eccentric shaft,rear axle shaft of car,parts of steam turbine,etc |

Chemical composition (%)

| C | Cr | Si | p | Mn | Ni |

| 0.37~0.45 | 0.90~1.20 | 0.17~0.37 | ≤0.035 | 0.90~1.20 | ≤0.030 |

Specifications: (approximate values)

| Quenching Temp | 860 ±15 °C |

| Cool Media | Oil |

| Tempering Temp | 600 ±15 °C |

| Cooling Media | air |

Mechanical features

| Tensile Strength (MPA) | Yield Strength(MPA) | Elongation(%) | Reduction In Area(%) | Impact Energy(J) | Hardness(HB) |

| ≥1080 | ≥ 930 | ≥ 12 | ≥ 45 | ≥ 63 | ≥217 |

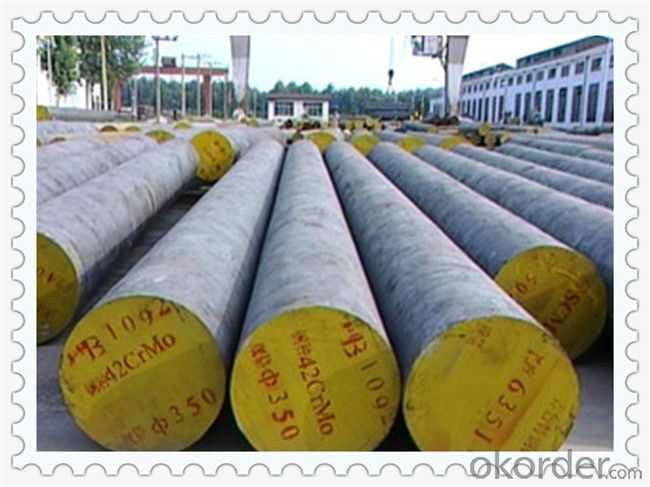

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

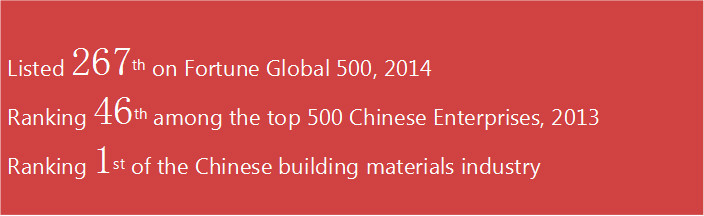

Company Information

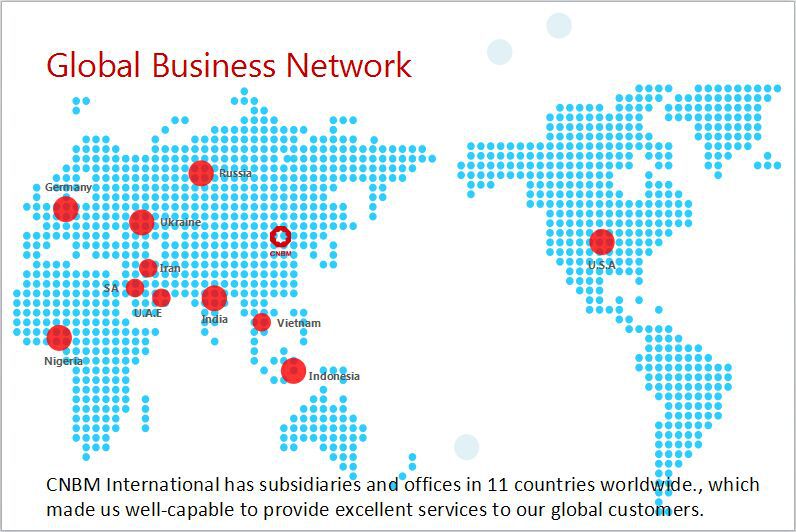

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What is the difference between hot rolled and cold drawn steel round bars?

- Hot rolled steel round bars are made by heating a billet or ingot of steel to a high temperature and then rolling it into the desired shape. This process results in a rougher surface finish and less precise dimensions compared to cold drawn steel round bars. Cold drawn steel round bars, on the other hand, are made by pulling a hot rolled bar through a die to achieve the desired shape and size. This process produces a smoother surface finish and more accurate dimensions. Overall, the main difference between hot rolled and cold drawn steel round bars lies in the manufacturing process and the resulting surface finish and dimensional accuracy.

- Q: Are steel round bars suitable for construction projects?

- Yes, steel round bars are suitable for construction projects. Steel round bars are versatile and durable materials that have a wide range of applications in the construction industry. They are commonly used in the construction of buildings, bridges, highways, and other infrastructure projects. Steel round bars offer several advantages for construction projects, including high strength, durability, and resistance to corrosion. They can withstand heavy loads and provide structural stability. Additionally, steel round bars can be easily shaped and manipulated to meet the specific needs and requirements of a construction project. Overall, steel round bars are a reliable and suitable choice for construction projects due to their strength, durability, and versatility.

- Q: How are steel round bars used in the construction of dams and reservoirs?

- Due to their strength, durability, and versatility, steel round bars are essential components in the construction of dams and reservoirs. These bars, typically made of reinforced steel, play a vital role in reinforcing the concrete structures that make up dams and reservoirs. In dam construction, steel round bars are primarily used as reinforcement in concrete walls and foundations. Strategically placed within the concrete, these bars provide additional tensile strength, preventing cracking and ensuring the structural integrity of the dam. By withstanding the enormous pressure exerted by the water, the reinforcement helps prevent leaks or potential failures. Furthermore, steel round bars are utilized to strengthen the spillway gates and control structures of dams and reservoirs. These gates regulate the flow of water and prevent overflow during heavy rains or floods. By reinforcing these critical areas with steel round bars, engineers guarantee that the gates can endure the forces exerted by the flowing water, maintaining their functionality and preventing potential damage. In addition, steel round bars are used in the construction of penstocks, which are large pipes or conduits that transport water from reservoirs to turbines in hydroelectric power plants. These bars reinforce the penstocks, ensuring they can withstand the high pressure of the water as it flows through and powers the turbines. In conclusion, steel round bars are extensively applied in dam and reservoir construction to enhance the strength and durability of various structural components. Their ability to reinforce concrete walls, foundations, spillway gates, control structures, and penstocks makes them indispensable in ensuring the longevity and stability of these crucial water infrastructures.

- Q: What is the Young's modulus of a steel round bar?

- The Young's modulus of a steel round bar typically ranges from 190 to 210 gigapascals (GPa).

- Q: Are steel round bars suitable for use in the construction of bridges?

- Yes, steel round bars are suitable for use in the construction of bridges. Steel round bars offer several advantages that make them an ideal choice for bridge construction. Firstly, steel round bars have high tensile strength, which means they can withstand heavy loads and forces without deforming or breaking. This is crucial for bridges as they need to support the weight of vehicles and pedestrians crossing over them. The high tensile strength of steel round bars ensures the structural integrity and safety of the bridge. Additionally, steel round bars have excellent durability and corrosion resistance. Bridges are often exposed to harsh environmental conditions, such as rain, snow, and saltwater, which can lead to corrosion and degradation of materials. However, steel round bars are specifically designed to resist corrosion, ensuring the longevity and reliability of the bridge. Moreover, steel round bars are readily available in various sizes and lengths, making them versatile and adaptable for different bridge designs and configurations. Their uniform circular shape also simplifies the construction process, as they can be easily cut, bent, and welded to fit the required specifications. Furthermore, steel round bars offer cost-effectiveness in bridge construction. They have a favorable strength-to-weight ratio, meaning they can provide the necessary strength while minimizing the overall weight of the bridge. This reduces the amount of material needed and lowers transportation costs during construction. In conclusion, steel round bars are highly suitable for use in the construction of bridges due to their high tensile strength, durability, corrosion resistance, versatility, and cost-effectiveness. They provide the necessary strength and reliability to support heavy loads and withstand harsh environmental conditions, ensuring the safety and longevity of the bridge.

- Q: Can steel round bars be used in food processing industries?

- Steel round bars are indeed suitable for use in food processing industries. The food industry often opts for steel as it offers exceptional durability, strength, and resistance against corrosion. Food processing equipment, such as mixers, conveyors, grinders, and slicers, can incorporate steel round bars. Moreover, steel round bars are also applicable in the creation of food storage containers, shelves, and racks. Nonetheless, it is crucial to guarantee that the steel employed in food processing industries adheres to food-grade standards, ensuring utmost hygiene and safety.

- Q: What are the advantages of using heat-treatable steel round bars?

- Using heat-treatable steel round bars offers several advantages: 1. Strength Enhancement: Controlled heating and cooling processes can be applied to heat-treatable steel round bars, which enhance their strength and hardness. This renders them suitable for applications demanding high strength and durability. 2. Enhanced Resistance to Wear: Heat treatment enables the development of a hardened surface layer on the steel round bars, significantly improving their wear and abrasion resistance. As a result, they are ideal for use in industries such as manufacturing, construction, and automotive, where components experience heavy wear and tear. 3. Tailored Customization: Heat-treatable steel round bars possess the advantage of easy customization to meet specific requirements. By adjusting the heat treatment process, the bars' hardness, strength, and other mechanical properties can be tailored to suit different applications, ensuring optimal performance. 4. Convenient Machinability: Heat-treatable steel round bars generally exhibit good machinability, allowing for easy cutting, drilling, or shaping into various forms without compromising their structural integrity. This convenience reduces production time and costs. 5. Versatility: Heat-treatable steel round bars find versatile applications across a wide range of industries, including construction, manufacturing, oil and gas, automotive, and aerospace. They are commonly utilized in the production of shafts, gears, bolts, axles, and other critical components. 6. Long-term Cost-effectiveness: Although heat-treatable steel round bars may initially have a higher cost compared to non-heat-treatable or lower-grade steels, their durability and enhanced properties make them cost-effective in the long run. The improved strength and wear resistance contribute to a longer service life, reducing the need for frequent replacements and maintenance. In conclusion, the utilization of heat-treatable steel round bars offers a multitude of benefits, including increased strength, improved wear resistance, customized properties, easy machinability, versatility, and long-term cost-effectiveness. These advantages position them as the preferred choice for demanding applications requiring high-performance materials.

- Q: Is round steel round steel?

- Round steel is a solid strip of steel whose cross section is round. The specifications are expressed in millimeters of diameter, such as "50", which means a round bar of 50 millimeters in diameter.

- Q: What are the advantages of using nickel-chromium-titanium alloy steel round bars?

- Some advantages of using nickel-chromium-titanium alloy steel round bars include their high strength and durability, excellent corrosion resistance, and good heat resistance. These alloy steel round bars also offer superior wear resistance and can withstand harsh environments. Additionally, they have good machinability, making them suitable for various applications in industries such as aerospace, automotive, and oil and gas.

- Q: What are the different treatments available for steel round bars?

- There are several different treatments available for steel round bars, including heat treatment, surface treatment, and coating. Heat treatment involves processes such as annealing, quenching, and tempering to improve the material's strength, hardness, and ductility. Surface treatments, such as polishing, grinding, or shot blasting, are used to enhance the surface finish and remove any imperfections. Coatings, such as galvanizing or painting, provide protection against corrosion and improve the overall appearance of the steel round bars.

Send your message to us

Round Steel 5115 Steel Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords