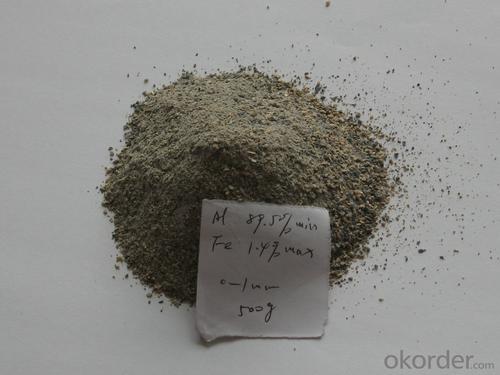

Raw Materials for Refractory:Rotary Kiln / Round Kiln Calcined Bauxite for Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pack

| Packaging Details: | 1.25kg/Bag 2.As your demands |

| Delivery Detail: | 30 days after down deposit |

Al2O3 85% Rotary Kiln Calcined Bauxite for Refractory Castables

Specifications&Data

What is the details of our steel fiber reinforced refractory castable?

Steel fiber reinforced refractory castable is a special castable which is added steel fiber into the castable,can improve the toughness,mechanical strength,thermal shock resistance and spalling resistance.

What is the Feature of Our steel fiber reinforced refractory castable?

1.High mechanical strength,

2.Good thermal shock resistance,

3.Good toughness and anti-stripping,

4.High refractoriness,

5.Tiny linear variation,no cracking,

6.Resistant to scour and erosion,

7.Good volume stability under high temperature.

What is the Applications of our steel fiber reinforced refractory castable?

Steel fiber reinforced refractory castable is mainly used in heat treatment furnace,heating furnace,soaking pit furnace,tundish slag dam weir,seconclary refining and the catalytic cracking unit etc key part of kiln furnace and thermal equipment.

What is the Technique Data of our steel fiber reinforced refractory castable?

Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

- Q: What is refractory brick?

- Capability1. Refractory brick is also known as firebrick. It is faint?yellow or brownish. Refractory brick with 770 ℃ at high temperatures is called for short firebrick. It is mainly used for building and smelting furnace. It is a refractory material made by fring refractory clay or other refractory material.

- Q: Who knows the setting requirements of roofing fire barrier zone?

- curtain wall style architecture should meet the following requirements: The space between the inner cavity of the base wall and curtain wall and base wall, pier?between?two?windows, window sill wall and skirt wall should be sealed by the fire-proof?sealing?material at each floor. I hope I can help you!

- Q: Does anyone know the difference between refractory and thermal insulation material?

- The main difference between insulation bricks and refractory bricks are as follows: 1. Insulation effect The heat conductivity cofficient of insulation bricks is usually 0.2-0.4 (average temperature of 350 ± 25 ℃) w / mk while the heat conductivity coefficient of refractory bricks is 1.0 (average temperature of 350 ± 25 ℃) w / mk or more. Thus it can be seen that the insulation effect of insulation bricks is much better than that of refractory bricks. 2. Refractoriness The refractoriness of insulation bricks is generally below 1,400 degrees centigrade while the refractoriness of refractory bricks is above 1,400 degrees centigrade. 3. Density Insulation bricks are generally light-weight insulation material, and the density is generally 0.8-1.0g / cm3. But the density of refractory bricks is above 2.0g / cm3.

- Q: Application of refractory materials in petroleum industry

- Our natural gas transportation, chemicals, equipment, packing, safety, insulation, and even building materials are available.

- Q: Who knows what kind of fire prevention materials are there?

- 1, Fire-proof board Fire-proof board is the most frequently used materials in the market. There are two kinds of fireproof boards which are commonly used; one is the high pressure decorative board, which has the advantages of fire prevention, damp proof, abrasion resistance, oil resistance, easy cleaning, and more variety of colors and designs. The other one is a glass magnesium fire board, the outer layer of which is a decorative material, the inner layer of which is a mineral glass magnesium fire material. It can resist 1500-degrees high temperature, but not suit for decoration. The installation of fireproof ceiling in the exit passageway, stair well and corridor can ensure safety evacuation, and protect people from the spread of the fire. 2 Fire-proof door Fireproof door is divided into wooden fire proof door, steel fire proof door and stainless steel fire proof door. Usually the fire proof door is used for the opening of the firewall, the entrance to the staircase, the evacuation of the aisle, the openings of the pipeline and other parts of the building, and it has an important role in fire separation and reducing the loss from fire. 2 Fire resisting shutter I hope it may be helpful to you.

- Q: The following statement is correct: artificial corundum has a high melting point and can be used as a high grade refractory material. The main component is silica dioxide

- Artificial corundum has high melting point and can be used as high-grade refractory material. The main component is silica, and the main component is aluminaThe chemist uses agate mortar friction solid reactant without solvent synthesis, the main component of agate is the main silicate is silicon dioxideThe early construction of the Three Gorges dam uses a lot of cement, which is made of silicate materialIn the summer, tourists wear by adding cuprous oxide silica made of glass color glasses to protect eyes [] color glasses is added to the material made of silver, it is now possible to have more advanced material, but the middle school stage is said with silver bromideIt sees light, decomposes easily, and combines easily, so use it.Solar cells can be made of silicon material, and its application is favorable to environmental protection and energy saving

- Q: What are the types of refractory sealant?

- Intumescent fireproof sealant: It has a characteristic of volume expansion when heated in the fire. Elastic fireproof sealant: Fire-resisting sealant with a certain to scalability (displacement capability) . Applications: Intumescent fireproof sealant is mainly used for sealing of single or small size bunches of cables through holes and filling of the gaps between the cables. Elastic fire resisting sealant is mainly used for fireproofing and sealing of construction joints (such as curtain wall gap).

- Q: What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q: What's the fire resistance test method of doors and roller shutters?

- Fire resistance test method of doors and roller shutters: This standard specifies the fire resistance test method for roller shutter doors under standard fire conditions. The method is used to test the fire resistance of the ventilating duct when bearing the external fire (A duct) and internal fire (B duct). Fire resistance test of vertical ducts may be conducted referring to this standard. 1.Test specimen1.1 The test specimen is obtained by cutting from any part of the qualified metal tube unless otherwise relevant standard or mutual agreement specifies the cutting position of the metal tube. 1.2 Length of the specimen: L≈2.5D+50mm (D: outer diameter of the metal tube). The cut surface of the specimen must be perpendicular to the axis of the metal , and the seamed edge of the cut should be round off. Test method GB243-82 of metal tube necking 2. Test procedures 2.1 In the test, punch or press the metal tube into the tapered conical seat (see Figure) with a hammer or press machine, and make it uniformly diminished to the regulated shrinkage X which is calculated according to the following formula: Test method GB243-822 for metallic pipe necking: The inner wall of the seat cover used in the test should be polished, and has certain hardness and is coated with lubricating oil. Its conicity is 1:10, 1:5 or others in accordance with relevant standard provisions. If there is no provision, then adopt the conicity of 1:10. This standard is not suitable for: a) The pipeline whose fire resistance depends on the fire resistance of the ceiling; b) The pipeline with access door, unless otherwise the access door is included into the pipeline and tested together; c) The pipeline with two or three sides; d) Fume exhaust pipes;

Send your message to us

Raw Materials for Refractory:Rotary Kiln / Round Kiln Calcined Bauxite for Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords