Roller for Steel Rolling Mill Forged Mill Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roller for Steel Rolling Mill Forged Mill Roll

Products Description

Centrifugally cast compound steel back -up rolls have a shell of cast steel with alloying elements such as Ni,Cr,Mo.After heat-treatment the roll shell get a fine temper structure, which exhibits good strength and ductility combined with high fatigue properties. When used, the roll shows a high wear and spalling resistance all the time.

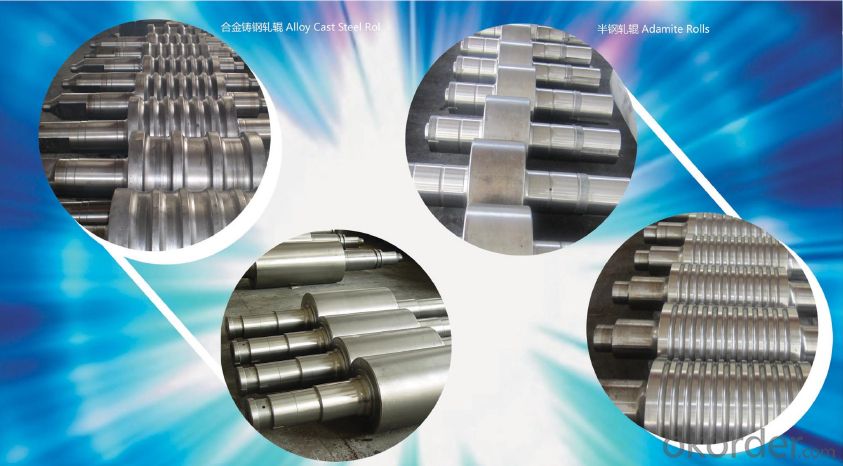

Products Pictures

Chemical Composition:

Classification | C | Si | Mn | P | S | Ni | Cr | Mo |

CrMo semi-chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

CrMo indefinite chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

NiCrMo indefinite chilled nodular castiron rolls(Ⅰ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.50-1.00 | 0.20-0.60 | 0.20-0.80 |

NiCrMo indefinite chilled nodular castiron rolls(Ⅱ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 1.01-2.00 | 0.30-1.20 | 0.20-0.80 |

Nodular pearlitic rolls(SGPI) | 2.90-3.60 | 1.40-2.20 | 0.40-1.00 | ≤0.15 | ≤0.03 | 1.50-2.00 | 0.10-0.60 | 0.20-0.80 |

Nodular pearlitic rolls(SGPⅡ) | 2.90-3.60 | 1.20-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.01-2.50 | 0.20-1.00 | 0.20-0.80 |

Nodular pearlitic rolls(SGP Ⅲ) | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.51-3.00 | 0.20-1.00 | 0.20-0.80 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 2.90-3.60 | 1.20-2.20 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.01-3.50 | 0.20-1.00 | 0.50-1.00 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 2.90-3.60 | 1.00-2.00 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.51-4.50 | 0.30-1.50 | 0.50-1.00 |

NiMo nodular cast iron roll( Ⅰ) | 2.90-3.50 | 1.50-2.40 | 0.40-0.80 | ≤0.05 | ≤0.03 | 1.00-2.50 | 0.10-0.50 | 0.40-0.80 |

NiMo nodular cast iron roll( Ⅱ) | 2.90-3.50 | 1.20-2.40 | 0.40-0.80 | ≤0.10 | ≤0.03 | 2.51-3.50 | 0.10-0.50 | 0.40-1.00 |

Physical Performance:

Products | Barrel Hardness (HSD) | Neck Hardness (HSD) | Tensile Strength (Mpa) |

CrMo semi-chilled nodular cast iron rolls | 40-55 | 35-55 | >300 |

CrMo indefinite chilled nodular cast iron rolls | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls(Ⅰ) | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls (Ⅱ) | 60-70 | 35-55 | >300 |

Nodular pearlitic rolls (SGPI) | 60-70 | 35-55 | >450 |

Nodular pearlitic rolls (SGPⅡ) | 55-65 | 35-55 | >450 |

Nodular pearlitic rolls (SGP Ⅲ) | 62-72 | 35-55 | >450 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 55-78 | 32-45 | >350 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 55-78 | 32-45 | >350 |

NiMo nodular cast iron roll( Ⅰ) | 42-52 | 32-43 | >300 |

NiMo nodular cast iron roll( Ⅱ) | 42-52 | 32-43 | >300 |

Quotation Elements

| ITEM | QUOTATION ELEMENTS |

1 | What kind of products the factory produce? Hot Rolled Steel Coil? Cold Rolled Steel Coil? Wire Rod? Rebar? |

2 | Production Process of Roll --Cast or Forged |

3 | Grade of Roll |

4 | Chemical Composition of Roll |

5 | Physical Property of Roll: Hardness/Tensile Strength/Elogation/Bening Strength |

6 | Drawing of Roll |

7 | Quantity |

8 | Delivery time |

Quality Control and Package

Products Display

- Q: How are hard alloy fittings machined and polished?

- Cutting tools or ceramic cutting tools for cubic boron nitride material, cobalt alloy cutting tools, etc.,Diamond grinding materials for polishing.

- Q: One can write on the hard alloy on the pencil, what's the name ah, who knows.

- You need it. It's all there. You're over there

- Q: What are the features of cemented carbide YG8 knives?

- Pig iron and non-ferrous metal processing. Can also be used in general stainless steel rough processing

- Q: What are the well-known brands of cemented carbide materials at home and abroad?

- Foreign - Sweden Sandvik, Germany - Luxemburg, American Kenna, Israel - Domestic - hard line iscar; diamond, Zigong the Great Wall, Xiamen gol-egret etc..Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q: What kind of cemented carbide is the most wearable?

- Carbide wear is due to the grain size and the cobalt content determines the finer granularity of cobalt content is lower, the higher hardness and lower hardness should be mentioned is the selection of wear-resistant hard alloy not only the hardness to see the use of general cutting hard alloy material with YW2 a relatively high hardness but if the working conditions impact operations more frequently if it should take into account its toughness but the toughness and hardness is conflicting under such circumstances can choose the class YG fine grain alloy

- Q: Japan steel tungsten carbide which is good

- Japan steel tungsten carbide recommended Kunshan aloi precision mould Co. Ltd, Japan Istanbul technology research of copper tungsten alloy used for professional sales of Japanese steel tungsten carbide and discharge EDM, silver tungsten alloy, copper alloy; discharge EDM tungsten copper, copper thread electrode; non-standard thread electrode, thread grinding machining

- Q: We'll drill on the stainless steel column. Which bit is better?

- If it's cylindrical carbide, it's better to be on the drill bit or as a guide

- Q: I would like to use carbide cutting tools, car work, ordinary A3 steel or 45 steel, lathe speed to play more appropriate, the workpiece surface quality is better?

- My car operation for more than 8 years, according to your car parts, actually hit 600 on the coarse, fine car or 1600 rpm, finish good, cutting speed is not too fast, the general lathe is mid-range open 6 can, keep your car parts after.

- Q: What blade does the high carbide material use?

- No ceramic blade, with PCD, the wear resistance of the ceramic blade or worse, the car hard alloy finishing non diamond tool, we have tried before, the crude car available the whole CBN tool, we use the case of personal data, some contact, welcome to consult

- Q: How hard is the carbide knife?

- The sintering temperature of the cemented carbide is about 1200 degrees centigrade. The welding temperature of the tool copper is about 850 degrees, the brazing of silver is about 700 degrees centigrade, the temperature of the metal cutting point is about 800 degrees, and the cutting temperature of the woodworking will not exceed 100 degrees centigrade.

Send your message to us

Roller for Steel Rolling Mill Forged Mill Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords