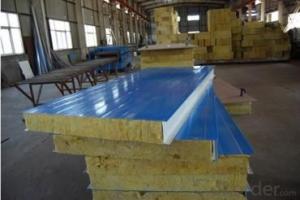

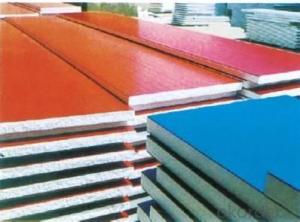

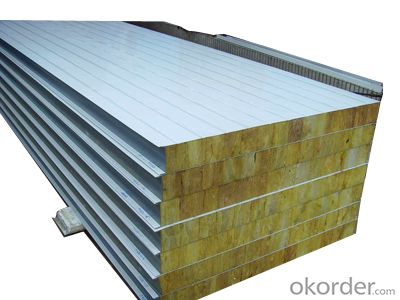

Rock Wool Composite Sandwich Panel Best Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

Specifications

rock wool composite sandwich panel

1. Light weight

2.Excellent sound and heat insulation

3. Excellent fireproof

Product Description

The Characteristics of our Rock Wool sandwich panels

Light weight

Excellent sound insulation and heat insulation

Easy installation

Fireproof and water proof

Long life:10-15years

Beautiful appearance

The specification of our Rock Wool Color Steel Sandwich Panels

Item Data

Effective Width: 1150MM/960MM/950MM

Length: Can be customized

Materials: Rock Wool, Color steel sheet

Structure: Upper and lower layer: Color steel sheet

Middle: Rock Wool

Density of Rock Wool: 80-300KG/M3

Thickness of color steel sheet: 0.3-0.8MM

Thickness of Rock Wool: 50-250MM

Colors: Blue, white or according to your requirements

- Q: What is the average thermal expansion coefficient of steel sheets?

- The average thermal expansion coefficient of steel sheets varies depending on the specific type of steel and its composition. However, a commonly accepted average value for the thermal expansion coefficient of steel sheets is around 12 x 10^-6 per degree Celsius (12 parts per million per degree Celsius). It is important to note that this value is an approximation and can vary slightly depending on the specific grade and composition of the steel being used.

- Q: Can steel sheets withstand extreme temperatures?

- Yes, steel sheets can withstand extreme temperatures. Steel has a high melting point and is known for its excellent heat resistance, making it suitable for use in various industries that require materials to endure extreme temperatures.

- Q: Stainless steel plate and steel welding

- It is better to use argon arc welding or white steel welding rod, with electrode generally 3.2 or 2.5 can be, the color will change with some, wipe it will be good.

- Q: Can steel sheets be used for water tanks or reservoirs?

- Yes, steel sheets can be used for water tanks or reservoirs. Steel is a durable and corrosion-resistant material that can effectively store and contain water. Proper sealing and coating techniques are employed to prevent rusting and ensure the longevity of the tank or reservoir.

- Q: What are the different shapes available for steel sheets?

- There are various shapes available for steel sheets, including but not limited to flat sheets, coils, strips, plates, and perforated sheets.

- Q: Can steel sheets be used for food processing or storage?

- Yes, steel sheets can be used for food processing or storage. Steel is a durable and hygienic material that is commonly used in the food industry due to its resistance to corrosion, easy cleaning, and ability to maintain proper food safety standards.

- Q: How can steel plates with a thickness of 1MM be welded?

- 1mm steel plate is best made by spot welding or flash welding, for example, electrical welding will cause plate deformation

- Q: What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets is generally higher compared to fiberglass sheets.

- Q: Can steel sheets be used for interior wall cladding?

- Yes, steel sheets can be used for interior wall cladding. Steel provides durability, strength, and a sleek aesthetic, making it a popular choice for modern and industrial interior designs.

- Q: Are steel sheets suitable for high-temperature insulation?

- No, steel sheets are not suitable for high-temperature insulation as they have poor thermal insulation properties and can conduct heat easily.

Send your message to us

Rock Wool Composite Sandwich Panel Best Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords