SMC Sheet - Rock Wool Blanket with Wire Mesh, Water Repellant, Asbestos Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

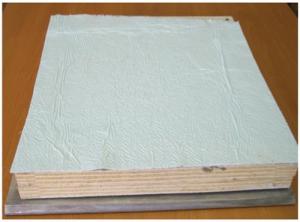

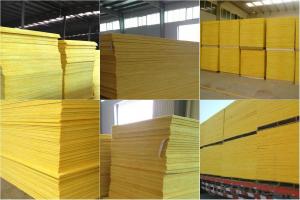

CNBM rock wool blanket with wire mesh Overview:

CNBM rock wool blanket with wire mesh is a robust insulation product stitched on one side with galvanized or stainless steel wire mesh and comes in various thickness and density.

CNBM rock wool blanket with wire mesh Product Specifications¼

Density(kg/m3) | Width(mm) | Thickness(mm) | Length(m) | Facing |

60-150 | 600 | 30-200 | 2.5 , 3 , 5 | wire mesh |

We can make special production according to your requirement.

Rock Wool Blanket With Wire Mesh Technical Parameters:

Item | Unit | Index | Standard |

Density | Kg/m3 | 60-200kg/m3 | GB5480.3 |

Average value of fiber | um | 4-7 | GB5480.4 |

Slag ball content (granule diameter) | % | 6 | GB5480.5 |

Volume water absorption | % | 2 | GB/GB16401-1996 |

Heat absorption | % | 1 | GB5480.7 |

Moisture resistivity | % | 98 | B10299-88 |

- Q: What composite material is used for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc..

- Q: The difference between glass fiber reinforced plastic antenna and cannon antenna

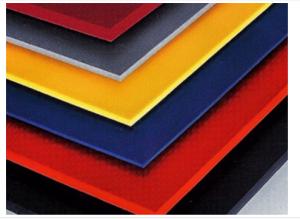

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q: Which is good for SMC composites and honeycomb composites?

- 3D printing can now print cellular structures directly.

- Q: Does floor heating emit toxic gas?

- In the ceramic tile surface drops the right amount of water, after a period of time, looks at the ceramic tile bottom surface whether has the seepage phenomenon, if does not have, is the high grade ceramic tile, if has, is inferior ceramic tile

- Q: In recent years, what new materials have come into use in the automotive interior, or in the future?

- In the past 20 years, the energy crisis and the rise in oil prices prompted the automobile lightweight gradually become the development trend of the new car, but also makes people to pay attention to the development of LFT low density material, LFT material properties and processing technology has also been improved.

- Q: Is the SMC material poisonous?

- This material is very good, non-toxic, give you a link, you refer to, remember to give a adoption Oh!

- Q: Thickening mechanism of Magnesium Oxide by SMC

- Magnesium Oxide in the production process, according to the needs of glass steel manufacturers to change the Magnesium Oxide indicators, in general, the active Magnesium Oxide in the glass steel industry is relatively good.

- Q: Where can I supply the SMC sheet machine set?

- If it is here in Shandong, Yantai, I know that Yantai Laizhou Feng based Machinery Co., Ltd., the production of SMC sheet machine set is good. Before, with the company Yang boss had traded

- Q: How is glass fiber reinforced plastic water tank made?

- FRP hand lay up tank: made of resin glass cloth paste hand processing tank frame surface

- Q: Where is the difference between glass fiber reinforced plastic cable tray and SMC cable trough?

- Ordinary bridge, pultrusion process, resin, calcium powder, glass fiber and so on, the price is cheaper. Use on common cable

Send your message to us

SMC Sheet - Rock Wool Blanket with Wire Mesh, Water Repellant, Asbestos Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords