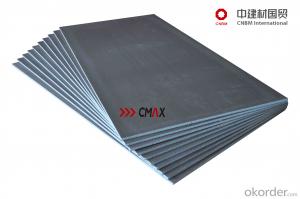

Rigid Xps Foam Board - White Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | X350 | Thickness: | 10-120mm | Color: | White / Light yellow / Blue /Green /Pink |

| Density: | 28-55 kg/m3 | Width: | 600mm / 900mm / 1200mm | Length: | 1200mm-3000mm(or any) |

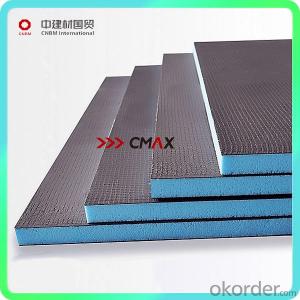

| Marketing Name: | White Extruded Polystyrene Board | Surface: | Withskin / Roughing / Embossing | Edge Shape: | SL SS T&G |

Packaging & Delivery

| Packaging Detail: | Plastic Bag Packing,68.4M3/40'HQ,Customer Label offered. |

| Delivery Detail: | 15 days |

Specifications

White Extruded Polystyrene Board

1.Thickness:10-120mm

2.Width:600-1200mm

3.Density:28-50Kg/m3

Product Description

Feininger White Extruded Polystyrene Board

XPS Extruded Polystyrene Foam Board Production Process: Polystyrene Granule, Talcum Powder, Masterbatch, Blowing Agent are mixed and melted in Extruder.The melt material will be extruded out of Slot Die, then through Calibrator, we reach a panel shape. After cooling, cutting, edge trimming, we will pack in water-proof plastic bag. This is the XPS Foam Board in market.

Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

Lightweight: volume optimization and easy to handle

Resistance to deformation

Resistance to impact

Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendlyRecyclable: Polyfoam can be 100% recyclied

Technical data sheet of White Extruded Polystyrene Board

Density | Kg/m3 | 31~50 |

Thermal conductivity, 90 days, 10°C | W/mK | 0.027~0.03 |

Compressive strength at 10% deflection or yield, (vertical) | kPa | ≥250 |

Tensile strength | kPa | ≥250 |

Water absorption | Vol-% | <=1.00% |

Capillarity | nil | nil |

Coefficient of linear thermal expansion | mm/mK | 0.07 |

Temperature limits | °C | -50°C, +75°C |

Packaging & Shipping

Feininger White Extruded Polystyrene Board

Plastic Bag Packing

68.4M3/40HQ

Container Loading

Size Length (mm) | Pcs/Pack | M2/Pack |

1200*600*50 | 10 | 7.2 |

2400*600*50 | 10 | 14.4 |

2440*600*50 | 10 | 14.64 |

2500*600*50 | 9 | 13.5 |

Our Services

Manufacture brand-new Feininger White Extruded Polystyrene Board

Carry out on-line quality supervision and test the insulation material before shipping

Pack XPS Foam in plastic bag

Issue Test Report

Ship the material by full container load

Make arrangement of transportation

Instruct how the XPS Foam Board is applied.

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- 2 fastener type steel pipe stent construction must be prepared before the construction program

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Mainly for insulation to reduce heat loss. So use a good insulation material insulation. Hope it helps you.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Caigang rock wool sandwich panel Scope Caigang rock wool sandwich panels for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling , Cut off and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding the right amount of binder, curing processing and made. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on. Color rock wool sandwich panels Product Features 1. Rock wool is inorganic insulation materials, iron ore slag as the main raw material, by melting, with high-pressure steam jet cooling, with a light, thermal conductivity is small, good elasticity , Non-combustible, non-rotting, non-rotting, chemical stability, and excellent sound insulation.2 The rock wool sandwich panels are widely used in addition to the general structure of heat insulation and insulation To the use of a variety of fire insulation places. Caigang rock wool sandwich board specifications thickness Caigang rock wool sandwich board sub-system board and manual board two, Caigang sandwich panel is made of two layers of color coated steel Layer, through the automatic compound molding machine, in the steel plate coated with adhesive glue, while embedded in the board on both sides of the thin-walled steel, the pressure, blanking made of sheet metal. . the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × . L × 1150 × . L × 1150 × . handmade rock wool color steel sandwich panel specifications: L × 985 × . Sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. . rock wool density: ≥ 120kg / m. thermal conductivity: ≤ 0.046w / m.k. combustion performance: A-level (non-combustible)

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- But its assembly is more complex and is not conducive to high-level construction, safety performance Dingzao cut to cut the salt tax is also poor, if the assembly is very easy to accident, and susceptible to natural factors and reduce its safety, As more and more emphasis on the protection of green today, it is bound to be replaced by steel scaffolding fastener type steel scaffolding with easy processing, easy handling, versatility and other advantages, is currently the largest use of China, the most common use of a scaffolding, but this scaffolding security is equally poor, the construction efficiency Low, scaffolding maximum erection height of 33 meters, can not meet the development needs of high-rise building construction bowl button assembly disassembly is relatively simple, the assembly performance is also good, more in the United States, China seems to use is not very wide But personally think that the future bowl button scaffolding will certainly be popular, there are prospects aluminum scaffolding is mainly lightweight, corrosion-resistant But not a high degree of construction, can not be high-level construction the disc does not seem to use the fastener with the bowl button type, universal joint do not understand So, personally think that in China fastening scaffolding or the mainstream, bowl button-style prospects are good

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- The honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- That is, can be in the farthest bowel forging forging treadmill punch fist away from the pull up the most important things tower crane top of the car can move back and forth he moved to the farthest place to pull up the heaviest weight is slightly! The

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- In when Edison in the study of incandescent bulbs, in the white hot filament inserted between a metal sheet

- Q: What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q: How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

Send your message to us

Rigid Xps Foam Board - White Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords