Reinforcing Twisted Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Reinforcing Twisted Steel Bars

Description of Reinforcing Twisted Steel Bars

1, Diameter: 5.5mm-10mm Reinforcing Twisted Steel Bars

10m- 40mm Reinforcing Twisted Steel Bars

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Reinforcing Twisted Steel Bars

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

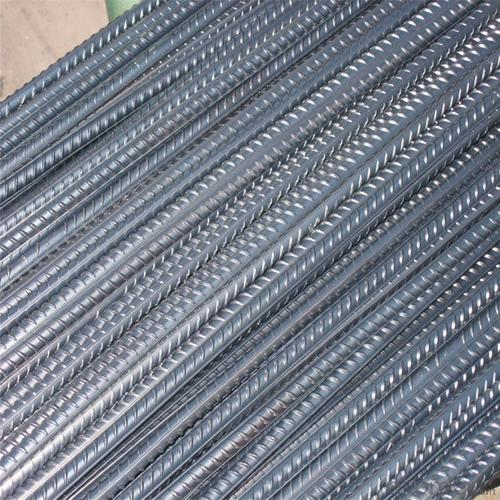

Products Show of Reinforcing Twisted Steel Bars

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the main applications of special steel in the defense electronics?

- Special steel is extensively used in defense electronics for various applications. It is primarily used for manufacturing components that require high strength, superior corrosion resistance, and excellent electromagnetic shielding properties. Special steel is crucial for producing military-grade electronic enclosures, connectors, and circuit boards, ensuring the protection and reliability of sensitive electronic equipment in harsh environments. Additionally, it is utilized in the production of radar systems, missile guidance systems, and communication equipment, where its exceptional thermal stability, durability, and electromagnetic compatibility play a vital role in enhancing the performance and effectiveness of defense electronics.

- Q: What are the different stamping grades of special steel?

- The different stamping grades of special steel include stainless steel, high-strength steel, tool steel, and alloy steel. Each grade has unique properties and characteristics that make them suitable for various stamping applications.

- Q: What are the different methods for improving the fatigue strength of special steel?

- There are various ways to enhance the fatigue strength of special steel: 1. Heat treatment is a commonly used approach, involving processes like annealing, quenching, and tempering. These treatments refine the steel's microstructure, reduce impurities, and boost fatigue resistance. 2. Surface treatments, such as shot peening and nitriding, can also enhance fatigue strength. Shot peening bombards the steel surface with small metal particles, inducing compression stress that prevents crack formation and propagation. Nitriding diffuses nitrogen into the surface layer, creating a hard and wear-resistant nitride layer that improves fatigue resistance. 3. Alloying special steel with specific elements, like chromium, molybdenum, or vanadium, can significantly improve fatigue strength. These elements form carbides or nitrides, acting as barriers against crack propagation. 4. Applying protective surface coatings, like electroplating, hot-dip galvanizing, or physical vapor deposition (PVD), can enhance fatigue strength. These coatings act as barriers against environmental factors that may cause corrosion or surface damage, ultimately extending the steel's fatigue life. 5. Grain refinement can be achieved through processes like severe plastic deformation or equal channel angular pressing (ECAP). By refining the grain size, the steel's fatigue strength can be improved, as fine-grained steels have higher resistance to crack initiation and propagation. 6. Residual stress management plays a crucial role in enhancing fatigue strength. Techniques like stress relieving or shot peening can reduce tensile residual stresses, which are detrimental to fatigue resistance. It's important to consider specific requirements, the type of special steel, and the intended application when selecting the most suitable method for improving fatigue strength.

- Q: What are the different methods of testing the quality of special steel?

- There are various methods to test the quality of special steel, including mechanical tests such as tensile testing, hardness testing, impact testing, and fatigue testing. Additionally, chemical analysis techniques like spectroscopy and metallography can be used to determine the chemical composition and microstructure of the steel. Non-destructive testing methods like ultrasonic testing and magnetic particle inspection are also commonly employed to detect any defects or anomalies in the steel.

- Q: What are the different methods of surface electropolishing for special steel?

- Special steel can undergo surface electropolishing using various methods, each with its unique benefits and applications. 1. Immersion Electropolishing: To achieve a smooth and polished finish, the special steel components are immersed in an electrolyte bath, and a direct current is passed through the solution. This method is ideal for large and complex parts, offering uniform surface improvement on all exposed areas. 2. Electrolytic Electropolishing: By applying a direct current directly to the surface of the special steel component using an electrode, the surface dissolves, resulting in a reflective and smooth finish. This technique allows precise control over the process and is suitable for smaller or intricate parts, targeting specific areas that require improvement. 3. Reverse Pulse Electropolishing: A combination of direct and reverse current pulses is utilized to achieve an exceptional surface finish. The reverse current pulses reduce surface roughness and eliminate embedded particles or contaminants. This method is especially beneficial for special steel components that require enhanced corrosion resistance and improved cleanliness. 4. Magnetic Field-Assisted Electropolishing: Applying a magnetic field to the electropolishing process can enhance the polishing rate and surface finish. The alignment of the electrical current by the magnetic field improves material removal, resulting in a smoother and more uniform surface. This method is preferred for difficult-to-polish special steels or those with complex geometries. 5. Flow-Assisted Electropolishing: By using a flowing electrolyte solution, the electropolishing process is enhanced. The flowing solution aids in removing dissolved material from the surface and prevents the formation of gas bubbles, resulting in a more efficient and smoother polishing. This method is suitable for large or flat special steel components requiring a high-quality surface finish. In conclusion, the choice of the appropriate method for surface electropolishing of special steel depends on specific component requirements, such as size, geometry, and desired surface finish. Each method has its advantages and considerations, and seeking guidance from an experienced electropolishing specialist is advisable to determine the most suitable approach.

- Q: Can special steel be used in the production of hydraulic components?

- Yes, special steel can be used in the production of hydraulic components. Special steels, such as stainless steel or high-strength alloy steels, offer excellent corrosion resistance, high strength, and durability, making them suitable for hydraulic applications where resistance to pressure, fluid flow, and environmental factors is crucial.

- Q: What are the challenges in heat treating special steel?

- Some of the challenges in heat treating special steel include achieving uniform heating and cooling rates, controlling distortion and warping, managing the formation of unwanted phases or microstructures, maintaining precise temperature control, and ensuring consistent and repeatable results. Additionally, special steels may have specific alloying elements or compositions that require specialized heat treatment processes or equipment, further adding to the complexity and challenges in heat treating these materials.

- Q: How does special steel contribute to the defense sector?

- Special steel plays a crucial role in the defense sector by providing various benefits and applications that enhance national security. Firstly, special steel is known for its superior strength, durability, and resistance to wear and corrosion. These properties make it an ideal material for the production of military equipment and weaponry. Special steel is used in the manufacturing of tanks, armored vehicles, naval ships, and aircraft carriers, ensuring their structural integrity and protection against enemy attacks. Additionally, the use of special steel in the construction of ballistic armor and bulletproof vests enhances the safety of soldiers on the battlefield. Moreover, special steel alloys offer excellent thermal resistance and high-temperature capabilities, making them suitable for the production of jet engines, turbines, and rocket components. These materials can withstand extreme conditions, enabling faster and more efficient military aircraft, missiles, and space exploration vehicles. Furthermore, special steel is used in the defense sector for its electromagnetic properties. It is employed in the development of radar systems, communication devices, and electronic warfare equipment. Special steel alloys can effectively shield against electromagnetic interference, ensuring secure and reliable communication in critical defense operations. Additionally, special steel plays a vital role in the production of precision tools and machinery used in the defense sector. It offers high machinability, allowing for the fabrication of complex components with tight tolerances. Special steel is used in the manufacturing of military-grade cutting tools, drills, and machine parts, enhancing the efficiency and effectiveness of military operations. In summary, special steel contributes significantly to the defense sector by providing strength, durability, resistance, and various other crucial properties. Its applications in military equipment, weaponry, armored vehicles, aircraft, and electronic systems enhance national security, protect soldiers, and enable advanced defense capabilities.

- Q: Is special steel suitable for marine applications?

- Yes, special steel is suitable for marine applications. Special steel alloys, such as stainless steel, are highly resistant to corrosion from seawater and provide excellent strength and durability in harsh marine environments. They are widely used in the construction of ships, offshore platforms, and other marine structures due to their ability to withstand the corrosive effects of saltwater and maintain structural integrity over extended periods.

- Q: What are the main factors affecting the fatigue strength of special steel?

- Several main factors influence the fatigue strength of special steel: 1. Material composition: The fatigue strength of special steel is determined significantly by its chemical composition. Alloying elements like carbon, chromium, molybdenum, and nickel can improve the material's ability to withstand cyclic loading and enhance its resistance to fatigue. 2. Microstructure: The fatigue strength of special steel is greatly affected by its microstructure, including grain size, crystallographic texture, and the presence of precipitates or phases. Fine-grained structures generally have higher fatigue strength due to reduced stress concentrations and improved resistance to crack initiation and propagation. 3. Surface condition: The fatigue strength of special steel can be significantly impacted by the surface finish and integrity. Surface defects such as scratches, notches, or roughness can act as stress concentrators and initiate fatigue cracks. Proper surface treatments like grinding or shot peening can reduce stress concentrations and introduce compressive residual stresses, improving fatigue resistance. 4. Heat treatment: The fatigue strength of special steel can also be influenced by the heat treatment process used to modify its structure and properties. Appropriate heat treatment techniques like quenching and tempering can optimize the material's microstructure, enhance its hardness, and improve its resistance to fatigue. 5. Loading conditions: The fatigue strength of special steel is greatly influenced by the type and magnitude of cyclic loading applied to it. Factors such as stress amplitude, mean stress, load ratio, and frequency of loading can all impact the material's fatigue life. 6. Environmental conditions: The fatigue strength of special steel can be decreased by the presence of corrosive environments, high temperatures, or other harsh conditions. Environmental factors can accelerate crack initiation and propagation, leading to reduced fatigue life. Selecting corrosion-resistant alloys or applying protective coatings can mitigate the adverse effects of the environment on fatigue strength. By considering and optimizing these factors, manufacturers and engineers can enhance the fatigue strength of special steel, ensuring its reliability and longevity in various applications.

Send your message to us

Reinforcing Twisted Steel Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords