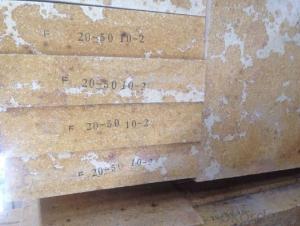

Silica Brick for Glass Furnace G-95A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX silica brick using high quality silica as raw material to ensure superior performance of silica bricks, the raw materials is high quality dinas rock with SiO2 of 99% min. Its unique structure helps ease forming. Moreover, advantages of complete transformation after sintering and lower residual quartz enable to produce super-duty silica bricks.

Performance:

The silica bricks for glass furnace is characterized by high purity, less impurity, good corrosion resistance, higher bulk density, complete phase transformation, lower residual quartz, high RUL, lower thermal expansion and stable volume at high temperature. This leads to increase in service life of glass furnace and reduction in energy consumption. These products have found wide application in crown and key areas and been highly appreciated by clients.

Application

CMAX Silica bricks are commonly applied in

Coke oven

Hot blast stoves

Glass furnace

Technical Data

ITEM | For Hot-Blast Stoves | For Glass Furnace | ||||||

S-94 | S-95 | S-95B | G-94 | G-95A | G-95B | G-96A | G-96B | |

SiO2, % | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 96 | ≥ 96 |

Fe2O3, % | ≤ 1.5 | ≤ 0.5 | ≤ 1 | ≤ 1.5 | ≤ 1.2 | ≤ 1.2 | ≤ 0.8 | ≤ 1 |

Residual Quartz, % | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ||||

Apparent Porosity | ≤ 23 | ≤ 23(24) | ≤ 21(23) | ≤ 24 | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) |

True Density, g/cm 3 | ≤ 2.35 | ≤ 2.34 | ≤ 2.33 | ≤ 2.35 | ≤ 2.35 | ≤ 2.34 | ≤ 2.34 | |

Cold Crushing Strength, Mpa | ≥ 29.4 | ≥ 30(27) | ≥ 30(20) | ≥ 30 | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) |

Refractoriness Under Load, º C | ≥ 1650 | ≥ 1600 | ≥ 1630 | ≥ 1660 | ≥ 1650 | ≥ 1680 | ≥ 1670 | |

Permanent Linear Change, % | 1500º CX4h, ± 0.2 | 1450º CX2h, ± 0.5 | ||||||

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- The ability of alkali resistance is poor, the thermal shock stability is the worst, and it is scrapped at one time. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: The brick is mainly used in the place?

- Open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Heating calcination is the best way to extend this sort of impurity removal. Remove impurities

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: Physical solid waste disposal

- The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick for Glass Furnace G-95A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords