Raw Materials for Refractory:Refractory Grade Calcined Bauxite for Alumina Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite for Alumina Cement

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

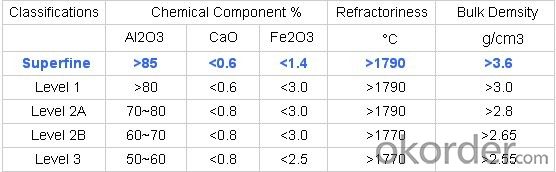

Calcined Bauxite Specifications

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

1) The bauxite for aluminum industry in defense, aerospace, automotive, electrical, chemical, and daily supplies;

2) Bauxite clinker processed into fine powder and made after the casting mold. Used in military, aerospace, communications, instrumentation, machinery and medical equipment sector;

3) The bauxite can be used in refractory products. The refractoriness of high-alumina clinker is up to 1780 . Its features are chemical stability strong, and physical properties of sound;

4) It can manufact alumina cement, abrasive materials and aluminum compounds.

Pictures:

Remarks:

1) If you have special requirement for the specifications, we can have a talking to know if we can meet it. Usually, our skills and equipments are no problem. It's up to the production cost related to the bauxite raw ores we purchase;

2) Wide sizes variety is available as per customer's request.

- Q: Does anyone know what kind of light fireproof materials are there?

- 二, 1, Gypsum plaster board With the building plaster as main raw material, gypsum plaster board is a kind of processed plate made by a special board for protective with an addition of additives and fibers as board core. Gypsum plaster board is characterized by light weight, sound insulation, heat insulation, strong processing performance and simple construction method. 2, Gypsum block Gypsum block is a kind of lightweight building gypsum product which is mainly made of building gypsum, and by adding water, stirring, casting and drying. During the process, , the fiber reinforced materials or light aggregates are allowed in, and the foaming agent can also be added. It has many advantages, such as sound insulation and fire prevention, convenient construction and so on. It is a kind of new and healthy wall material which produces low carbon, enhances environmental protection, and caters to the the times. 3, Fly ash brick is a new type of wall material, and bulk density is one of the main technical indexes. The weight of bulk density can be controlled according to the need of construction and adjustment of technical formula. The dry bulk density of the fly ash brick is about 1540 to 1640 kg / m 3, slightly lighter than the clay brick (1601800 kg /m 3). The flexural and compressive strength of fly ash brick is mainly determined by the production process, the formula and the hydrothermal synthesis reaction mode as well as the need of construction. According to the standards of architectural material industry (JC239 - 2001) released by People's Republic of China, the average value of the flexural strength is 2.5 ~ 6.2Mpa, compressive strength is between 10 ~ 30Mpa. I hope this will be helpful to you

- Q: What are the standards of refractory concrete ?

- It can be divided into: 1. Ordinary refractory concrete Aggregates used include high alumina, clay, silica, basic materials (magnesite, chromite, dolomite, etc.) or special materials (carbon, silicon carbide, zircon, etc.). It can also use several combination of refractory material. 1. Thermal insulated refractory concrete It is mainly formulated with refractory light aggregates. The light aggregate used can be expanded perlite, vermiculite, ceramsite, porous chamotte, alumina hollow ball, etc. It can also be a combination of several refractory light aggregates or combination of the refractory aggregates. The aggluetination material used in refractory concrete can be high alumina cement, phosphate binders, water glass binder and clay, etc.

- Q: What characteristics do A grade external wall fireproofing material have?

- 1. Save space and reduce costs; 2. Fireproofing, green and environmental protection; 3. Waterproofing; 4. Sound insulation; 5. Thermal insulation; 6. Install easily and shorten the construction period; 7. High safety performance.

- Q: What are the characteristics of thealuminium oxide refractory?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- You can add some animal hair, like bristles. After all, we don’t have so much hair. Remember not to use cement, because it will crack. Instead, make use of animal hair, lime, yellow mud and sand, after mixing up, and they would be firmer while in calcination.

- Q: Does the refractory material used in steelmaking all refer to refractory brick?

- For example, refractory castable doesn't only refer to refractory brick, but also some bulk material and ramming?mass. Desulfurizer belongs to ferrous metallurgy auxiliary material.

- Q: Who can introduce the external wall thermal insulation materials fire rating regulations?

- According to public fire-fighting [2007] No. 182, the contents of the notification on the implementation of a number of issues of national standards GB8624-2006 "building materials and products combustion performance classification", since there is large differences between the new version of the standard GB8624-2006 and the old version of GB8624-1997 in the principle, hierarchical structure and test methods. According to the cintent of notification, in order to ensure a smooth transition between the old and new standards, the current national standard "Fireproof? Specification of Building Interior Decoration?Design" GB50222, "fire?safety?rules of tall civil buildings design" GB50045, "Fireproof? Specification of Building Design" GB50016 have not completed the relevant amendments, the new classification method of GB8624-1997 and GB8624-2006 can be used for temporary reference in terms of combustion performance of materials . From GB8624-2006 standard implementation, the classification of combustion performance is too granular, which do not match to the actual construction of the current project in our country. Therefore, the relevant departments carry on the 3rd amendment for the GB8624-2006 standards, namely GB8624-2012, and it will be released on December 31, 2012 and implemented on October 1, 2013. The combustion grading requirements in the standard: Level A is non-combustible materials (products); level B1 is nonflammable material (products); level B2 is combustible materials (products); level B3 is flammable materials (products).

- Q: Who knows how many kinds of fireproof insulation materials are there in the market?

- The so-called A-level materials in fire insulation materials, namely, the WW non-combustible insulation materials, and the WW material s are A-level. Inorganic fireproof and thermal insulation materials can be used as wall insulation materials to replace red bricks, therefore, they, as thermal and cold insulation materials, can reduce the thickness of walls, and save energy, as well as expand applicable areas indirectly, decreased structure weight. They are very good.

- Q: What's the heat conductivity coefficient, specific heat capacity and density of the refractory material of magnesite-chrome brick and magnesia-alumina brick respectively?

- It is suggested that you find some samples of well-known manufacturers, such as Ogilvy and Mather Group, and that will be more correct.

- Q: What are the types of steel refractory materials

- (1) clay refractory brick (2) high alumina refractory brick

Send your message to us

Raw Materials for Refractory:Refractory Grade Calcined Bauxite for Alumina Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords