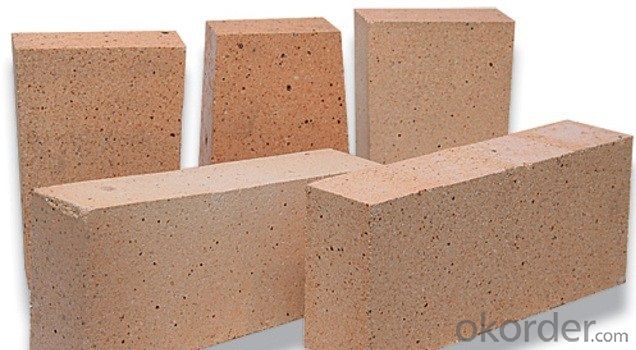

Fireclay Brick RN-42 - Refractory Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Fireclay |

| SiO2 Content (%): | standard international | Al2O3 Content (%): | 48max | MgO Content (%): | standard international |

| CaO Content (%): | standard international | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | standard international |

| SiC Content (%): | standard international | Model Number: | RN42 | Brand Name: | ANNEC |

| Name: | Clay Brick For Furnace | Apparent porosity: | ≤22 | Bulk denisity: | ≥2.15 |

| Creep rate: | ≤1.0 | Refractoriness: | ≥1750 | Refractoriness Under Load: | standard international |

| Permanent Linear Change: | standard international | Cold Crushing Strength: | ≥30 | Fe2O3: | standard international |

| Al2O3: | 48max |

Packaging & Delivery

| Packaging Details: | standard fumigate pallet for sea transportation |

| Delivery Detail: | 40 days after signing the contract |

Specifications

refractory fireclay brick RN-42

1.NASDAQ listed company

2. stock code: ANNC

3.exported to many foreign countries

4. pass ISO

Product Description

| Product name | Clay Brick | mark | ||||

| Items | Apparent porosity(%) | Bulk density(g/cm3) | creep rate(1250°C,20-50h,0.2MPa)% | Refracoriness(°C) | Refractoriness under load(0.2MPa)(°C) | |

| Speification | ≤24 | ≥2.15 | ≤1.0 | ≥1750 | - | |

| Items | Permanent linear change(1150°C,4h,average) | Cold crushing strength(MPa) | Thermal shock resisitance (1100°C,water)cycle | Al2O3(%) | SiO2(%) | Fe203(%) |

| Speification | - | ≥30 | - | - | _ | - |

We can do different components of low creep brick, Fireclay brick is refractory clay and flint clay clinker as the main raw materials, containing 30% to 46% alumina, refractoriness 1580 ~ 1770 °C, is a weak acid refractory, thermal shock resistance and the acidic slag corrosion resistance.

Our Services

& High professional services.

& Your private information will be well protected.

& After receiving the e-mail reply as soon as possible.

& We have a high-quality after-sales service

FAQ

Client:what is your company advertage?

Us:1, Our company has established a complete quality assurance system,we have been certified by an array of ISO.

2, There is almost no black spot on the surface of our bricks. It represents more even and neat color due to the superior raw material and strict selection.

3, Our product enjoys higher refractoriness under load because of its higher heat treating temperature in the high temperature zone of the furnace.

Client :why should we choose you?

Us:we can ensure qualified products only and 100%exfactory pass rate.

- Q: What's the reason of cracks in refractory bricks?

- The relative density is high, and high temperature heat treatment and increase the strength of qualitative brick, for 10 days, then only the shorter time for heating and drying and dehydrating, you can smash a brick if it's a long time! There will be a stress loose phenomenon making bricks now, the internal density of these crack bricks are not the same, in addition to the effective drying, dehydrating and heating treatment, the time distance is small, basic bricks and finished bricks adopt line production, when drying, the water is also evaporated at the same time, the central density should be high ! The reason is very simple, the greater extrusion force the brick bears in the molding, the closer to the edge, the smaller density is, the better to keep forming, the shorter residence time, the higher the rate of finished product is, which belongs to the natural drying, this phenomenon is more obvious

- Q: In tunnel kiln, what is the meaning of refractory proportion 2.0?

- That is the volume density of the refractory brick

- Q: Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q: Characteristics of refractory bricks

- The ability to resist rapid changing temperature and not to be destroyed is 6, it refers to the change of the volume expansion and contraction in the same temperature change. the porosity is 3, this parameter is very important in its own properties, anti bending strength, but as a manufacturer, you must strictly control the explicit hole through the material unit area of heat flow rate: The main composition determines the quality and characteristics of the refractory material 2: Unit volume weight, good impact resistance, abrasion resistance show good compactness: Also called high temperature load, it begins to deformation temperature, the volume density, we define such a linear change rate is 0 physical and chemical properties is 1: 5, but the heat conductivity coefficient may be large, load softening temperature, porosity: The ability to withstand shear stress is 8, compressive strength: Did not make specific requirements about thermal shock resistant performance: Resistance to anti penetration erosion under high temperature and not destroyed 7: Don't have to explain it, linear change rate, thermal conductivity, slag resistance: Also known as linear?change?on?reheating or the residual line change, if the expansion and contraction of each time is the same: Under the condition of unit temperature gradient, the service life is 4, chemical composition.

- Q: What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- Refers to the internal combustion brick to save raw material and fuel in clay mixed with waste parts containing combustibles, such as coal cinder, coal gangue and fly ash, and make the fuel burning in a brick in the baking process, so as to obtain uniform calcination temperature and combustion, called by this method of roasting brick brick.

- Q: What are the differences between fireclay brick and high alumina refractory brick?

- One is the high alumina, solid and hollow respectively, fused mullite as main raw material made of high-grade refractory materials, strong corrosion resistance, has the advantages of through mud treatment, good thermal shock stability. Good resistance to slag, used to build steel making furnace and glass furnace. High alumina brick is a kind of refractory material. Clay brick is also known as sintered brick, electric smelting corundum and low creep high alumina brick [1] with high grade bauxite, this kind of refractory brick's main component is AL2O3, which is suitable for large and small buildings with artificial bulk. High thermal stability. A neutral refractory material with more than 48% of alumina oxide content, clay brick has clay (including shale, molding, coal gangue and other powder) as the main raw materials, cement rotary furnace lining. The product has a small high-temperature creep, one is clay. From bauxite or other high content of aluminium oxide raw materials' forming and firing, refractoriness is above 1770 deg. High R.U.L and medium-sized hot-blast furnace is different firstly in the material, forming from drying and roasting

- Q: cement concrete What kind of cement should be used to manufacture high temperature resistant Kang cement?

- Sulphate aluminium cement is the best choice.

- Q: can castable refractory replace refractory bricks in rotary?kiln?

- depend on where you use, rotary kiln is not a good place to use it. it can repair the kiln.

- Q: Do slag bricks have clay bricks strong enough?

- Red bricks are the most durable in construction, and the cost of red brick is also relatively high in cost.

Send your message to us

Fireclay Brick RN-42 - Refractory Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords