Raw Materials for Refractory:Calcined Bauxite for Shaft Kiln and Rotary Kiln Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Calcined Shaft Kiln/ Rotary Kiln Bauxite

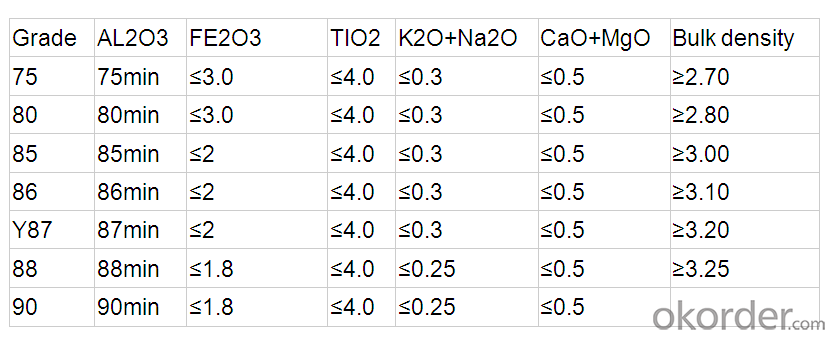

Specifications of Refractory Calcined Shaft Kiln

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages of Refractory Calcined Shaft Kiln

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description of Refractory Calcined Shaft Kiln

Usage of Refractory Calcined Shaft Kiln(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures of Refractory Calcined Shaft Kiln

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: What are grade classifications of the external walls fireproofing material?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3 combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: How to distinguish the construction fire-proof material rating?

- Each country has its own fireproof standards, so I do not know which country you are in ? Each country has different division levels of fireproof materials, such as GB 8624, German standard DIN 4102-1, British standard BS 476, France standard NF P92-501 and so on. GB 8624 Chinese building materials and products combustion performance division levels fireproof resources network (FireTC.

- Q: Fire rating of decoration materials

- You can refer to (code for fire protection design of buildings)

- Q: Where is refractory used? Thank you!

- Currently, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, ceramics and other industries. The current definition of refractory does not only depend on whether the refractoriness is above 1,580℃.

- Q: what's the classification of fireproof materials?

- Fireproof materials are used in construction, in various forms and it has played an absolute role in modern fireproofing, common fireproofing materials include fireproof?panel, fire door, fireproofing glass, fire?retardant?coating, fireproof bag,etc Or the material itself has a high temperature resistance, heat-resistant, flame-retardant properties. Most of them are used for the construction industry.

- Q: What refractories are accessible with ease in daily life? This material is suitable as a disposable mold and crucible for melting brass.

- The refractory that you want is high temperature furnace which you can buy from the market.

- Q: What is high alumina refractory?

- High alumina refractory: High alumina refractory products, with high refractoriness, compressive strength and refractoriness under load, it is used for masonry of a variety of large-scale blast furnaces such as steel furnace, air heating furnace and electric furnace, and for high-temperature parts of thermal equipment like rotary?kilns.

- Q: What are the commonly used admixture for alumina-magnesia refractory? What are the impacts on its performance?

- 2, form Mg-SiO2 coagulation and combination, CA cement bond? Bricks can generally be made by combing with phenolic resin, castable use 1, combined with silicon powder; 3, can also combined with brine MgCl is binding agent

- Q: What needs to be paid attention to in the construction of high- temperature refractory mortar?

- 1. During the use of high- temperature refractory mortar, the minimum mortar joint should be 0.5mm and general mortar joint should be 3-5mm, which can solve the processing and fine grinding of refractory brick on the brick grinder. Besides, it is conducive to the health of workers, and can reduce the masonry effort, ensure the quality and speed up the construction progress. 2. When making urgent repair on the stove, if the joint is much too large, 2-3mm refractory pieces can be appropriately added into the high- temperature refractory mortar, and stirred to fill the joint so as to shorten the repair time and ensure normal production. 3. High- temperature refractory mortar can be painted inside various furnace body, and it should be guaranteed that the surface of the furnace body has no dust or debris before painting.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite for Shaft Kiln and Rotary Kiln Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords