Q345 Pre-Galvanized Pipe2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What is the role of steel pipes in the construction of bridges and tunnels?

- The construction of bridges and tunnels heavily relies on steel pipes, which are widely used for various purposes due to their strength, durability, and versatility. When it comes to bridge construction, steel pipes are commonly utilized to fabricate the structural framework of the bridge. They act as the primary load-bearing members, providing support and stability to the entire structure. Steel pipes are particularly favored in bridge construction because of their high tensile strength, enabling them to withstand heavy loads, including the weight of vehicles and the dynamic forces generated by traffic. Steel pipes are also essential in the construction of bridge piers and abutments, which serve as the foundation and support for the bridge structure. To create sturdy foundations that can withstand the forces exerted by the bridge's weight and external factors such as wind, water currents, and seismic activity, steel pipes are often driven deep into the ground. Similarly, in tunnel construction, steel pipes play a critical role. They are extensively used for tunnel lining, which involves the installation of structural elements along the tunnel walls and roof to ensure stability and prevent soil or rock collapse. Steel pipes are commonly used as reinforcement elements, ensuring the structural integrity of the tunnel and protecting it from external pressures. Furthermore, steel pipes are utilized for underground utility systems in both bridges and tunnels. They act as conduits for various utilities, including water supply, electrical cables, gas pipelines, and communication lines. Steel pipes are ideal for these applications because of their corrosion resistance, ability to withstand high pressures, and long lifespan. In conclusion, steel pipes are crucial in the construction of bridges and tunnels as they provide strength, stability, and durability to these structures. They play a vital role in ensuring the safety and functionality of these critical infrastructure projects, allowing for efficient transportation and the seamless provision of utilities.

- Q: What material is RHS in the steel tube?

- RHS is a rectangular hollow section steel. The RHS structure represents a rectangular hollow section steel.

- Q: How are steel pipes transported and stored?

- Steel pipes are typically transported using trucks, trains, or ships, depending on the distance and quantity. These pipes are often stacked and secured with straps or chains during transportation to prevent any movement or damage. When it comes to storage, steel pipes are commonly stored in outdoor yards or warehouses. They are usually organized in neat rows or stacked on racks to maximize space and facilitate easy access. Additionally, pipes may be covered with weather-resistant materials to protect them from rust or corrosion during storage.

- Q: How many fasteners are there in a ton of steel tubes?

- The fastener generally refers to the intermediate connecting parts connecting two members, in the construction project for external diameter of steel pipe scaffold with 48mm fixation, the fastener is divided into rectangular fastener (cross directional fastener fastener) rotary fastener (universal movable fastener fastener) (a direct docking fastener fastener fastener) etc..

- Q: Can steel pipes be used for structural supports in buildings?

- Yes, steel pipes can be used for structural supports in buildings. Steel pipes are known for their strength, durability, and ability to withstand heavy loads. They have high tensile strength, which means they can withstand large amounts of tension and compression without breaking or deforming. This makes them ideal for structural applications in buildings where strong and stable supports are required. Steel pipes can be used for various purposes such as columns, beams, trusses, and even as the main support for the entire building. They are also versatile and can be easily fabricated and customized to fit specific design requirements. Additionally, steel pipes are resistant to fire, corrosion, and pests, making them a reliable choice for long-term structural support in buildings.

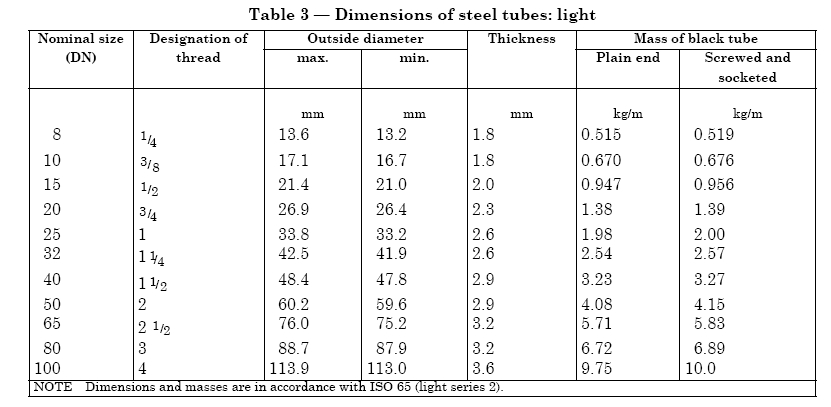

- Q: What is the meaning of "DN" and "Phi" in the dimensioning of steel pipe diameter and how to apply the mark?

- DN represents the path of the tube". Fair represents diameter. Path is the diameter of the fluid through which it should be inside. The diameter may be the outer diameter or the inner diameter. The diameter is only used when the pipe is used for flow through. Fair as long as the garden can be used. According to the requirements of mechanical drawing fair, DN text notes.

- Q: Can steel pipes be used for conveying natural gas?

- Certainly, natural gas can indeed be transported through steel pipes. In reality, steel pipes are frequently employed for this task owing to their robustness, long-lasting nature, and capacity to endure elevated pressures. Moreover, steel pipes exhibit exceptional resistance to corrosion, a vital feature when conveying natural gas containing impurities such as water and sulfur compounds. Furthermore, connecting various parts of the pipeline becomes effortless with steel pipes, thanks to their ease of welding. All in all, when it comes to conveying natural gas, steel pipes emerge as a trustworthy and secure option.

- Q: DN150 welded steel tubes one meter multiple

- Calculated theoretical weight (Kg) per inch of welded steel pipe = (outside diameter wall thickness) * wall thickness * 0.02466DN150 welded pipe, "150" means nominal diameter of 150mm. Its outer diameter is 165mm.

- Q: What are the common applications of seamless steel pipes?

- Due to their unique properties, seamless steel pipes are widely used in various industries. Here are some of the most common applications: 1. The oil and gas industry extensively utilizes seamless steel pipes for transporting oil, gas, and other fluids. These pipes are preferred because of their high strength, durability, and resistance to corrosion, making them suitable for harsh environments. 2. Seamless steel pipes are extensively used in construction projects, such as building, bridge, and tunnel construction. They are ideal for structural applications due to their ability to withstand heavy loads and provide excellent strength and stability. 3. The automotive industry relies on seamless steel pipes for manufacturing automotive parts, including exhaust systems, engine components, and hydraulic systems. These pipes offer high strength, reliability, and resistance to heat, making them suitable for demanding automotive applications. 4. Various mechanical and engineering applications benefit from the usage of seamless steel pipes. They are commonly used for carrying fluids, gases, and steam, as well as for transmitting power in machinery and equipment. 5. Power plants extensively utilize seamless steel pipes for transporting steam and hot water. These pipes are capable of withstanding high pressure and temperature, making them ideal for power generation applications. 6. The petrochemical industry heavily relies on seamless steel pipes for transporting chemicals, gases, and liquids. These pipes have excellent resistance to corrosion, which is essential when dealing with hazardous and corrosive substances. 7. The mining industry utilizes seamless steel pipes for various applications, including the transportation of slurry, water, and other mining-related fluids. These pipes offer durability, reliability, and resistance to abrasion, making them suitable for the challenging mining environment. 8. The aerospace industry finds applications for seamless steel pipes in manufacturing aircraft components, such as hydraulic systems, fuel lines, and structural parts. These pipes provide a high strength-to-weight ratio and resistance to extreme temperatures and pressure. Overall, seamless steel pipes play a crucial role in a wide range of industries. Their exceptional properties, including strength, durability, resistance to corrosion and high temperatures, make them an essential component in various industrial processes and infrastructure development.

- Q: Are steel pipes resistant to UV degradation?

- No, steel pipes are not resistant to UV degradation.

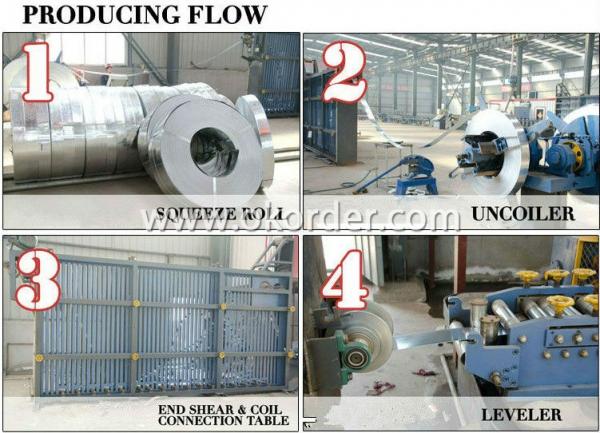

The main production and sale of galvanized steel, the thin-walled high-frequency welded pipe, galvanized pipe, square pipe, rectangular pipe, conduit, EMT conduit, greenhouse pipes, galvanized pipes, and other related products, annual production capacity of 40,000 tons. The company has independent export rights.

1. Manufacturer Overview

| Location | Tianjin ,China |

| Year Established | 2004 |

| Annual Output Value | Above 100milion rmb |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 38000squar meter |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Q345 Pre-Galvanized Pipe2

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords