Q235B spiral pipe can be processed inside and outside anti-corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

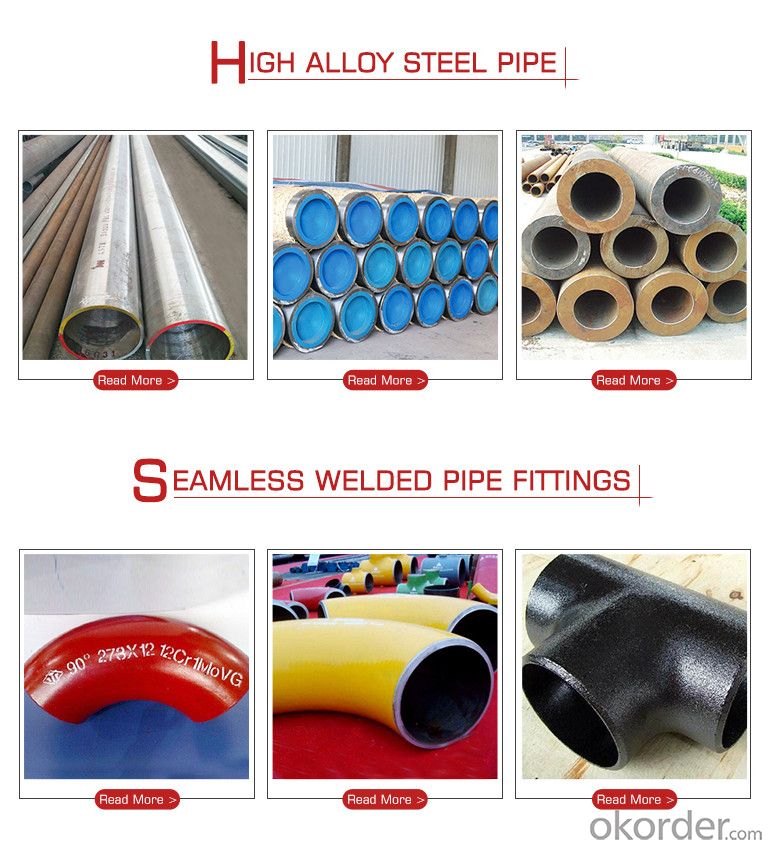

Our main products are: seamless steel tube (hot rolling, cold drawing);Spiral steel tube;Straight seam steel tube;Heat expanding steel tube;Large diameter thick wall steel tube;Alloy steel tube;Anti-corrosion and heat preservation steel pipe.Scope of seamless steel tube: diameter 57mm-910mm wall thickness 2.0mm-26mm;Double-sided submerged arc welding spiral steel tube: diameter: 219mm-3600mm; wall thickness: 6.0mm-30mm;Straight seam resistance welded steel tube (ERW) : diameter 21.3mm-457.2mm wall thickness 1.8mm-14.27mm and straight seam double-sided submerged arc welding pipe: diameter 310mm-3200mm wall thickness 6mm-60mm;Thermal expansion seamless steel tube: diameter 245mm-920mm wall thickness 6.0mm-34mm;Large diameter thick wall steel tube: diameter 351mm-3600mm wall thickness 26mm-80mm. Seamless steel tube execution standard: GB/T8162 8163 3087 5310 6479 9948 5312.Helical steel tube executive standard: GB/T9711.1 9711.2 SY/T5037 5040 APTSPEC 5L.Straight seam steel pipe standards: GB/T3091971113793APISpec5L.Thermal expansion steel pipe executive standard: GB/T8162 8163 3091.Large diameter thick wall steel pipe executive standard: GB/T3091 3092 14980 13793.Alloy steel pipe standards: GB3087, 5310, 6479, 9948 SY/T6194API5CTAPI5LAPI5BASTM53M?ASTMA106 ASTMA213/213 m DIN17175.

According to customer requirements, the company can undertake steel tube of the single and double fusion bonded epoxy (FBE), double polyethylene powder (2 PE pipe) and three layers of polyethylene (3 PE steel pipe), double polypropylene (pp) and polypropylene (pp), three layer of epoxy coal tar anti-corrosion coating pipeline anticorrosion engineering and IPN8710 polymer anticorrosive coatings, cement mortar pipe wall corrosion pipe internal coating such as a variety of anti-corrosion structure of directly buried steel pipeline anticorrosion engineering and rock wool insulation sets of steel, black/yellow leather jacket polyurethane foam insulation pipe engineering, execution DIN30670?30671, SY/T4013 0315 standard, is widely used in oil, natural gas, gas, water and other long transmission pipelines and petrochemical enterprises urban central heating pipe network, gas pipe network and other projects, products with high strength, high pressure, easy to install, low cost, long service life and many other advantages, by the user's praise.

- Q: How do you repair damaged steel pipes?

- To repair damaged steel pipes, the first step is to assess the extent of the damage. If it's a small crack or hole, it can be fixed using a steel-filled epoxy or a pipe repair clamp. However, for more significant damage, such as extensive corrosion or a large rupture, cutting out the damaged section and replacing it with a new pipe is usually necessary. In some cases, professional welding or soldering may be required to ensure a secure and leak-proof repair.

- Q: Can steel pipes be used for underground culverts?

- Indeed, underground culverts can utilize steel pipes. Renowned for their robustness, longevity, and ability to withstand diverse environmental influences, steel pipes are ideal for subterranean applications. They exhibit exceptional resilience to substantial burdens, intense hydrostatic pressure, and the erosive impact of soil and water. Moreover, steel pipes offer a range of dimensions and thicknesses, enabling customization to meet precise project prerequisites. Nevertheless, prudent consideration must be given to variables such as soil attributes, water table elevations, and the likelihood of corrosion during the selection of the most fitting steel variant and protective coatings for the pipes.

- Q: What are the safety considerations when working with steel pipes?

- When working with steel pipes, there are several important safety considerations to keep in mind. Firstly, it is crucial to wear appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect the eyes from flying debris or sparks, gloves to protect the hands from sharp edges or hot surfaces, and steel-toed boots to protect the feet from falling objects or heavy equipment. Additionally, wearing a hard hat is recommended to protect the head from potential falling objects or overhead hazards. Next, it is important to be aware of the weight and size of steel pipes. Handling heavy pipes can put strain on the back and muscles, so it is essential to use proper lifting techniques and seek assistance when necessary. Using lifting equipment, such as cranes or forklifts, can also help prevent injuries related to heavy lifting. Another safety consideration is the risk of cuts or punctures. Steel pipes can have sharp edges or burrs, so it is important to handle them with care and wear appropriate gloves to reduce the risk of injury. Inspecting pipes for any defects or sharp edges before working with them is also recommended. Furthermore, working with steel pipes may involve welding or cutting, which can produce sparks, heat, and fumes. It is crucial to work in a well-ventilated area or use proper ventilation equipment to ensure the removal of harmful gases or fumes. Fire safety precautions should also be taken, such as having fire extinguishers nearby and following proper procedures for hot work. Lastly, it is important to be aware of potential hazards associated with working at heights or in confined spaces. When working on elevated platforms or scaffolding, fall protection measures, such as safety harnesses or guardrails, should be in place. In confined spaces, proper ventilation and monitoring for hazardous gases are essential to prevent asphyxiation or exposure to toxic substances. Overall, by following these safety considerations and adhering to proper procedures, the risk of accidents or injuries when working with steel pipes can be significantly reduced.

- Q: How are steel pipes used in the oil and gas industry?

- Steel pipes are widely used in the oil and gas industry for various purposes. They are primarily used for transporting and distributing oil and gas from extraction sites to refineries and end consumers. Steel pipes are also used in drilling operations, where they are utilized as casing and tubing to extract oil and gas from wells. Additionally, steel pipes are employed in the construction of storage tanks, pipelines, and other infrastructure required for the production, processing, and transportation of oil and gas. Overall, steel pipes play a crucial role in ensuring the efficient and safe operation of the oil and gas industry.

- Q: What are the different methods of bending steel pipes?

- There are several methods of bending steel pipes, including hot bending, cold bending, induction bending, rotary draw bending, and hydraulic pipe bending.

- Q: How are steel pipes used in the manufacturing of bridges?

- Steel pipes are commonly used in the manufacturing of bridges for various purposes, such as supporting heavy loads, providing structural strength, and ensuring durability. They are often used as piling foundations, allowing the bridge to be securely anchored to the ground. Steel pipes can also be used as bridge components, such as support columns, beams, and trusses, providing the necessary strength and stability to withstand the weight and forces exerted on the bridge. Additionally, steel pipes are used for drainage systems, allowing water to flow away from the bridge structure, preventing potential damage or erosion. Overall, steel pipes play a crucial role in the construction and structural integrity of bridges.

- Q: How are steel pipes used in the construction of solar power plants?

- Steel pipes are commonly used in the construction of solar power plants for various purposes. They are primarily utilized for the installation of solar panel mounting structures, which require sturdy and reliable support systems. Steel pipes are also used for the construction of infrastructure such as frames, racks, and supports for the solar panels. Additionally, they are employed in the installation of water and coolant systems, as well as for the transmission of fluids and gases within the plant. Overall, steel pipes play a crucial role in providing structural integrity and efficient functionality to solar power plants.

- Q: What are the different methods of joining steel pipes without welding?

- There are several methods of joining steel pipes without welding, including: 1. Mechanical Couplings: These couplings consist of two separate pieces that are attached to the ends of the pipes and then tightened together. They provide a secure and leak-proof connection without the need for welding. 2. Threaded Connections: In this method, the ends of the steel pipes are threaded to create a male and female connection. The pipes are then screwed together using pipe threads, providing a strong and reliable joint. 3. Flanged Connections: Flanges are used to connect steel pipes by bolting them together. The flanges have a flat surface with holes that align with corresponding holes in the opposite flange. Bolts are then inserted and tightened to create a tight seal. 4. Grooved Connections: This method involves grooving the ends of the steel pipes and then using grooved couplings to join them. The couplings have teeth that interlock with the grooves, creating a secure and rigid connection. 5. Compression Fittings: Compression fittings are used to join steel pipes by compressing a metal or plastic ring onto the pipe's outer surface. This creates a tight seal and a reliable connection, without the need for welding. 6. Adhesive Bonding: Special adhesives designed for metal bonding can be used to join steel pipes. The adhesive is applied to the surfaces of the pipes, which are then pressed together and left to cure, creating a strong and durable bond. 7. Clamping: Clamps can be used to hold steel pipes together, creating a temporary connection. This method is commonly used for testing purposes or in situations where the pipes need to be easily disassembled. Each of these methods has its own advantages and limitations, and the choice depends on factors such as the specific application, pipe material, and the required strength of the joint.

- Q: The plastic pipe and steel pipe difference

- The steel plastic pipe is a general term, which includes plastic pipe, plastic lined pipe. Plastic pipe external coating, zinc coated and so on in Shanghai, Fujian, Portland, professional in this area

- Q: Galvanized steel pipe in addition to good rust resistance, what are the advantages?

- It has the characteristics of corrosion resistance and wear resistance, so it can be used longer;

Send your message to us

Q235B spiral pipe can be processed inside and outside anti-corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords