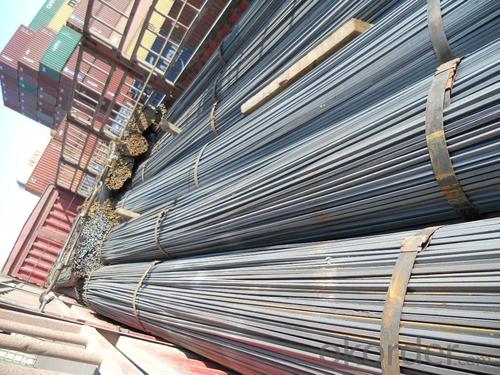

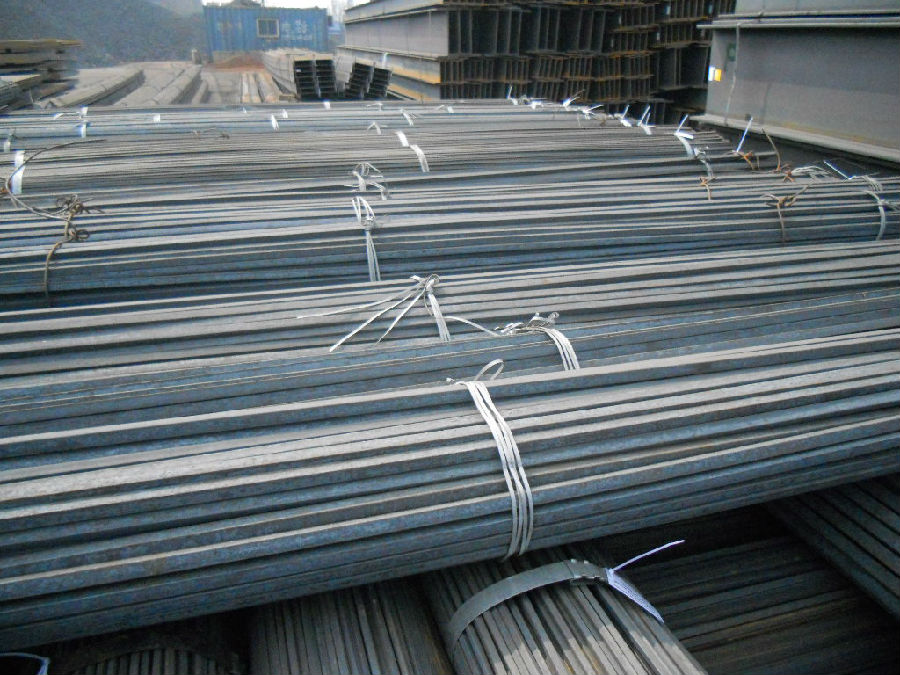

Cold Drawn Square Steel Q235 Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Cold Drawn Square Steel Q195 Q235

Grade: Q195, Q235

Size: 8-100mm

Length 6-12m

Best quality & Low price

Cold Drawn Square Steel Q195 Q235

Grade: Q195, Q235

Size: 8-100mm

Length 6-12m

Mild steel is sometimes referred to as carbon steel or plain steel. Typically, it is stiff and strong. Carbon steels

do rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most

fabrications. Mild Steel can be easily cut or drilled to meet your requests.

square bars are widely used for machine-made industry,chemical industry,spin,shipping industry, architecture,

food industry, housed.

| Technique | Hot rolled |

| Standard | GB,JIS,ASTM |

| Steel material | Q195 Q235B Q275 20Mnsi 3SP 5Sp |

| Size | 50mm x 50mm-150mm x 150mm or as per customers' requirement |

| Length | 6m-12m as standard |

| Application | Construction,Metallurgy,Carbon structural steel, Alloy steel, Gear steel, etc. |

| Quality | First quality |

| Delivery time | 25-45days or according to the order quantity or negotiation |

| Payment Terms | L/C, T/T |

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can a steel square be used for measuring the height of a flagpole?

- Using a steel square to measure the height of a flagpole is not possible. This tool, often referred to as a try square, is mainly used for measuring and marking 90-degree angles. It lacks the capability to measure vertical distances or heights. For this purpose, one would typically rely on a measuring tape, a laser distance meter, or any other device specifically designed for measuring vertical distances.

- Q: Can a steel square be used for checking the squareness of a disc sander table?

- No, it is not possible to use a steel square to check the squareness of a disc sander table. A steel square is specifically designed for measuring right angles and checking the squareness of objects with straight edges, like boards or workpieces. However, a disc sander table has a circular surface, and a steel square is not appropriate for accurately measuring the squareness of curved or circular surfaces. To determine the squareness of a disc sander table, it is necessary to use a specialized tool like a precision angle gauge or a dial indicator. These tools are capable of providing precise measurements and ensuring that the table is perfectly square, allowing for accurate sanding operations.

- Q: Can a steel square be used for measuring circular objects?

- No, a steel square cannot be used for measuring circular objects. A steel square, also known as a carpenter's square or a framing square, is a tool designed for measuring and marking right angles. It consists of a long straight edge and a shorter perpendicular edge, forming an L-shape. While it can be used for various purposes in carpentry and woodworking, it is not suitable for measuring curves or circular objects. For measuring circular objects, a tool such as a compass, a tape measure, or a set of calipers would be more appropriate.

- Q: Can a steel square be used for checking the squareness of a window opening?

- Yes, a steel square can be used for checking the squareness of a window opening.

- Q: How do you use a steel square to measure and mark 112.5-degree angles?

- In order to measure and mark a 112.5-degree angle using a steel square, it is necessary to adhere to a specific procedure. Below are the instructions on how to do it: 1. Start by placing the steel square on a flat surface or workpiece, ensuring its stability and security. 2. Identify the 45-degree angle on the steel square, which is formed where the long and short arms of the square meet. 3. Position the long arm of the square on the surface, aligning it with the reference line or edge from which you want to measure and mark the angle. 4. Gently rotate the steel square to the left until the short arm aligns with the desired angle. In this instance, you need to rotate the square approximately 2.5 degrees beyond the 45-degree angle to measure and mark a 112.5-degree angle. 5. Once you have adjusted the steel square to the correct angle, ensure its firm placement to guarantee accuracy. 6. Using a pencil or scribe, cautiously mark the desired angle along the edge of the steel square or on the workpiece. 7. Prior to proceeding with any further steps, double-check your measurement and marking to ensure accuracy. By adhering to these steps, you can effectively utilize a steel square to measure and mark a 112.5-degree angle. Remember to handle the square with care and verify your measurements for precise results.

- Q: Can a steel square be used for checking the squareness of cabinets?

- Yes, a steel square can be used for checking the squareness of cabinets. Steel squares are commonly used in woodworking and carpentry for checking the accuracy of right angles and determining squareness. By placing the steel square against the corners of the cabinet, you can easily determine if the cabinet is properly square or if adjustments need to be made. The straight edges of the steel square provide a reliable reference for checking the squareness of cabinets and ensuring their proper alignment.

- Q: What are some common applications for a steel square in flooring installations?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool used in various aspects of flooring installations. Here are some common applications for a steel square in flooring projects: 1. Layout and marking: A steel square is essential for accurate layout and marking of straight lines and angles on flooring materials. It helps ensure precise measurements and alignment during the installation process. 2. Cutting and shaping: One of the primary uses of a steel square is for cutting and shaping flooring materials such as tiles, laminate, or vinyl. By using the square's straight edge and 90-degree angle, installers can make accurate cuts and achieve clean, straight lines. 3. Checking for squareness: A steel square is useful for checking if walls or corners are perfectly square before starting a flooring installation. This ensures that the flooring materials are laid down evenly and without any gaps or uneven edges. 4. Determining rise and run: In projects involving stairs or other elevated platforms, a steel square can be used to determine the rise and run of each step. By using the square's measurements and angles, installers can calculate the correct dimensions for a safe and comfortable staircase. 5. Spacing and alignment: When installing flooring materials like hardwood or laminate planks, a steel square can be used to maintain consistent spacing and alignment between each piece. This helps create a uniform appearance and prevents any gaps or unevenness in the flooring. 6. Marking cutouts: In cases where flooring materials need to be cut to fit around obstacles or fixtures such as pipes or cabinets, a steel square can be used to mark precise cutouts. It ensures that the cuts are made accurately, resulting in a seamless fit around these obstacles. Overall, a steel square is an invaluable tool in flooring installations due to its versatility, accuracy, and ability to perform various tasks ranging from layout and marking to cutting and shaping materials. Its precise measurements and angles help ensure a professional and well-finished flooring project.

- Q: How do you use a steel square to measure the width of a countertop?

- To use a steel square to measure the width of a countertop, place one arm of the square flush against one edge of the countertop and extend the other arm across to the opposite edge. Ensure that the square is held firmly against the edges for an accurate measurement. Then, read the measurement markings on the square to determine the width of the countertop.

- Q: How do you use a steel square to determine the slope of a garden fence?

- To use a steel square to determine the slope of a garden fence, you would first need to gather a few materials such as a steel square, a level, a tape measure, and perhaps some stakes and string. 1. Begin by measuring the length of the fence line you want to check for slope using a tape measure. This will give you the horizontal distance you will be working with. 2. Choose a section of the fence line where you want to determine the slope. It is recommended to choose a relatively straight and level section for accuracy. 3. Next, place the steel square on the ground at the starting point of the section you chose. Ensure that the square's long side is parallel to the fence line. You can use stakes and string to help keep the square in place if necessary. 4. Use a level to adjust the steel square until it is perfectly level. This is important to ensure accurate measurements. 5. Once the square is level, use the tape measure to measure the vertical distance between the ground and the top edge of the steel square. This measurement will give you the rise of the fence line over the horizontal distance you measured earlier. 6. To determine the slope, divide the rise measurement by the horizontal distance. This will give you the slope ratio, typically expressed as a fraction or percentage. For example, if the rise is 2 feet and the horizontal distance is 10 feet, the slope would be 2/10 or 1/5, which can also be expressed as 20%. By following these steps, you can use a steel square to determine the slope of a garden fence accurately. This information can be helpful in ensuring proper drainage and stability of the fence, as well as for planning and designing other aspects of your garden.

- Q: Can a steel square be used for checking the squareness of a table saw fence?

- Yes, a steel square can be used for checking the squareness of a table saw fence. A steel square, also known as a carpenter's square or framing square, is a tool with a right-angle shape that can be used to ensure that the edges and corners of a workpiece or tool are perfectly square. To check the squareness of a table saw fence, simply place the steel square against the fence and align it with the blade of the table saw. If the square is properly aligned, the blade should be perpendicular to the fence, indicating that the fence is square. However, it is important to note that while a steel square can provide a quick and easy way to check squareness, it is always recommended to use a more precise measuring tool, such as a dial indicator or precision square, for accurate results.

Send your message to us

Cold Drawn Square Steel Q235 Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords