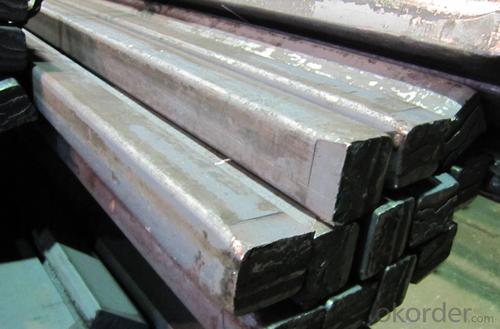

Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets stored to prevent rusting?

- Steel billets are typically stored in covered areas or warehouses to protect them from exposure to moisture and humidity, which can lead to rusting. They are also often coated with a rust inhibitor or protective oil prior to storage to provide an additional barrier against corrosion.

- Q: What are the main factors affecting the heat resistance of steel billets?

- The main factors affecting the heat resistance of steel billets include the alloy composition of the steel, the presence of impurities, the grain size of the steel, the heat treatment process, and the cooling rate during quenching.

- Q: How are steel billets used in the manufacturing of construction formwork?

- Steel billets are used in the manufacturing of construction formwork as they are often shaped and molded into various components, such as beams or columns, that provide essential structural support. These billets are strong and durable, ensuring the formwork can withstand the weight and pressure of poured concrete. Additionally, their malleability allows for customization, enabling the formwork to be precisely designed to meet the specific requirements of each construction project.

- Q: How do steel billets contribute to the manufacturing of consumer electronics?

- The versatility and durability of steel billets make them an essential component in the manufacturing of consumer electronics. These semi-finished steel products are hot-rolled into different shapes and sizes, allowing for a wide range of applications. One way in which steel billets contribute to the manufacturing of consumer electronics is by creating casings and structural components. Steel's strength and rigidity make it ideal for providing structural support and protecting electronic devices. Whether it's mobile phones, laptops, or gaming consoles, steel billets are used to produce outer casings that safeguard internal components from damage. Furthermore, steel billets are also used in the production of connectors and terminals found in consumer electronics. These small yet crucial parts enable the flow of electricity between different components, ensuring the smooth functioning of electronic devices. Steel's excellent electrical conductivity and resistance to corrosion make it a reliable material for these connectors, guaranteeing optimal performance and longevity. Moreover, steel billets contribute to the manufacturing of consumer electronics by being utilized in the fabrication of heat sinks. Heat sinks are essential in electronic devices as they dissipate excess heat generated by the components, preventing overheating and potential damage. Steel's thermal conductivity and heat resistance properties make it an ideal material for these heat sinks, effectively transferring heat away from critical components and ensuring the reliability and longevity of electronic devices. In conclusion, steel billets play a vital role in the manufacturing of consumer electronics by providing the necessary strength, durability, and thermal conductivity for various applications. Whether it's in the production of casings, connectors, or heat sinks, steel billets contribute to the overall quality and functionality of electronic devices, ensuring a seamless user experience.

- Q: What are the potential applications of steel billets in the medical sector?

- Steel billets have a range of potential applications in the medical sector, including the production of surgical instruments, orthopedic implants, and medical equipment. The durability and strength of steel make it suitable for manufacturing tools and devices that require high precision and reliability. Additionally, steel's resistance to corrosion and ability to be sterilized are valuable properties for medical applications.

- Q: How are steel billets used in the manufacturing of construction cranes?

- Steel billets are an essential component in the manufacturing of construction cranes. These billets, which are semi-finished metal forms, are typically made from molten steel that is cast into rectangular or square shapes. They are then further processed and transformed into various crane components. One crucial use of steel billets in the construction crane manufacturing process is for the production of structural elements. These billets are heated and rolled into long, slender beams or columns that form the backbone of the crane's structure. These beams provide the necessary strength and rigidity to support heavy loads and withstand the stresses encountered during crane operation. By using steel billets, manufacturers can ensure that the structural components of construction cranes possess the required durability and load-bearing capacity. Moreover, steel billets are also utilized in the production of crane boom sections. The boom is the extended arm of the crane that allows it to reach high elevations and transport heavy materials. Steel billets are reheated and shaped into cylindrical or rectangular sections, which are then welded together to form an elongated boom structure. The use of steel billets ensures that the boom sections have the necessary strength and stiffness to safely lift and maneuver heavy loads. Additionally, steel billets are employed in the manufacturing of other crane components such as pulleys, gears, and various fittings. These billets are forged, machined, or cast into the required shapes and sizes to create the intricate parts that enable the crane to function smoothly and efficiently. The high strength and versatility of steel make it an ideal material for these critical components. In summary, steel billets play a vital role in the manufacturing of construction cranes by providing the necessary raw material for the production of structural elements, boom sections, and other crucial components. Their strength, durability, and versatility make them an ideal choice for constructing cranes that can handle heavy loads and withstand the demanding conditions of construction sites.

- Q: What are the factors affecting the price of steel billets?

- There are several factors that can affect the price of steel billets. Some of the key factors include the demand and supply dynamics in the market, fluctuations in raw material prices (such as iron ore and coal), changes in energy costs, global economic conditions, geopolitical events, government policies and regulations, and technological advancements in the steel industry. Additionally, factors like currency exchange rates and transportation costs can also impact the price of steel billets.

- Q: What are the different methods of steel billet surface finishing?

- There are several methods of steel billet surface finishing that are commonly used in the industry. These methods include: 1. Shot blasting: Shot blasting is a common method used to clean and prepare steel billets for further processing. It involves propelling abrasive particles at high speeds onto the surface of the billets. This process removes any rust, scale, or impurities from the surface, resulting in a clean and smooth finish. 2. Grinding: Grinding is another method used to achieve a smooth and even surface finish on steel billets. It involves the use of abrasive wheels or belts to remove material from the surface of the billets. Grinding can be done manually or using automated machinery, depending on the requirements and size of the billets. 3. Polishing: Polishing is a process that is typically used to achieve a high-gloss, reflective finish on steel billets. It involves the use of polishing compounds and buffing wheels to smooth out the surface and enhance its appearance. Polishing is often used for decorative purposes or when a high-quality finish is required. 4. Acid pickling: Acid pickling is a method used to remove any oxide scale or rust from the surface of steel billets. It involves immersing the billets in an acid solution, such as hydrochloric acid, to dissolve the impurities. Acid pickling is an effective way to achieve a clean and uniform surface finish on steel billets. 5. Passivation: Passivation is a process that is often used to improve the corrosion resistance of steel billets. It involves the immersion of the billets in a passivating solution, typically a mixture of nitric acid and water, to remove any surface contaminants and promote the formation of a protective oxide layer. Passivation can help to prevent the formation of rust and extend the lifespan of the steel billets. Overall, the choice of method for steel billet surface finishing depends on the desired finish, the size and shape of the billets, and the specific requirements of the application. Each method has its own advantages and considerations, and it is important to carefully select the appropriate method to achieve the desired surface finish.

- Q: What are the potential risks associated with steel billet production?

- There are several potential risks associated with steel billet production. One significant risk is the high temperature involved in the process, which can lead to burns and fire hazards if not properly managed. Additionally, the handling of heavy machinery and equipment poses a risk of accidents and injuries to workers. The use of chemicals and hazardous substances in the production process can also pose health risks if not handled safely. Another potential risk is the emission of pollutants and greenhouse gases during production, contributing to environmental concerns. It is crucial for steel billet producers to implement appropriate safety measures, train their employees, and adhere to environmental regulations to mitigate these risks.

- Q: How are steel billets used in the production of flanges?

- Steel billets are used in the production of flanges by being heated and molded into the desired shape and size. The billets are typically forged, rolled, or machined to form the flange, which is then used to connect pipes or valves in various industrial applications.

Send your message to us

Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords