PVC Waterproofing Membrane with Single-Side Compounded with Fiber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane with Single-Side Compounded with Fiber

Product Description of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

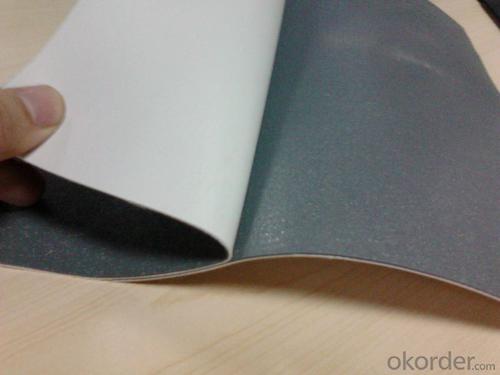

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

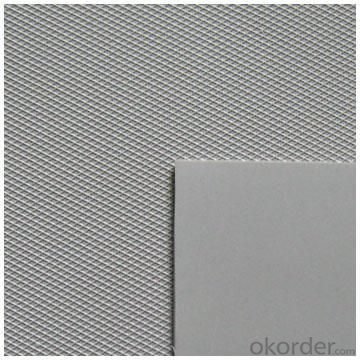

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

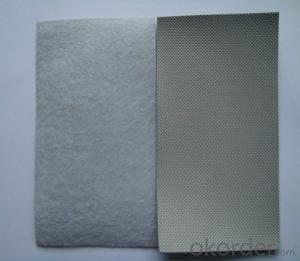

Classification of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

1. N: Homogeneous PVC membrane

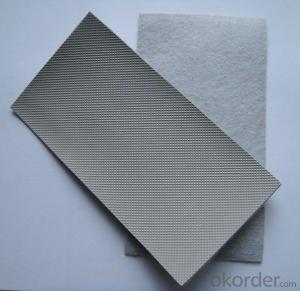

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Images of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

FAQ of PVC Waterproofing Membrane with Single-Side Compounded with Fiber:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes flexible?

- Yes, waterproofing membranes are typically flexible. They are designed to be pliable so that they can conform to the shape and movement of the surfaces they are applied to. This flexibility allows the membranes to effectively seal gaps, cracks, and joints, preventing water from infiltrating into the underlying structure. Furthermore, the flexibility of waterproofing membranes also enables them to withstand the expansion and contraction that occurs due to temperature changes or structural movements. Overall, the flexibility of waterproofing membranes is a crucial characteristic that ensures their durability and effectiveness in protecting structures from water damage.

- Q: Can a waterproofing membrane be applied to horizontal surfaces?

- Horizontal surfaces can indeed have a waterproofing membrane applied to them. In fact, it is quite common to utilize this method in order to safeguard and waterproof flat areas like roofs, decks, balconies, and the like. The membrane functions as a protective barrier, effectively preventing water from infiltrating the surface and causing harm. Typically, this membrane is crafted from a pliable material, such as rubber or modified bitumen, which easily conforms to the contours of the horizontal surface. Moreover, the membrane is specifically engineered to withstand foot traffic and other forms of weight, ensuring long-lasting protection. All in all, the application of a waterproofing membrane to horizontal surfaces proves to be a highly effective means of preventing water damage and prolonging the lifespan of the surface.

- Q: Can a waterproofing membrane be used on precast brass surfaces?

- Yes, a waterproofing membrane can be used on precast brass surfaces. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied to a variety of surfaces including concrete, metal, and precast materials. In the case of precast brass surfaces, the membrane can help prevent water penetration, which is particularly important in areas exposed to moisture such as bathrooms, kitchens, or outdoor environments. By applying a waterproofing membrane, the precast brass surface can be effectively protected from water damage, corrosion, and potential deterioration, ensuring its longevity and preserving its aesthetic appearance.

- Q: What is the cost of a waterproofing membrane installation?

- The cost of a waterproofing membrane installation can vary depending on various factors such as the size and complexity of the area to be waterproofed, the type of membrane being used, and the location of the project. Generally, the cost can range from $3 to $10 per square foot. For a basic installation, which typically involves applying a liquid or roll-on membrane, the cost can be on the lower end of the spectrum. However, if the project requires additional preparation work such as repairing cracks or uneven surfaces, the cost may increase. Moreover, the type of membrane being used can also impact the cost. There are different types of waterproofing membranes available, including bituminous membranes, thermoplastic membranes, and elastomeric membranes. Each type has its own advantages and disadvantages, and the cost can vary accordingly. Additionally, the location of the project can influence the cost. Labor and material prices may vary depending on the region or city, and contractors may also consider transportation costs if the project is in a remote area. It is important to obtain multiple quotes from reputable contractors to determine the specific cost for your waterproofing membrane installation. Consulting with professionals and discussing your specific requirements will help you get an accurate estimate for your project.

- Q: Can waterproofing membranes be used on wood surfaces?

- Waterproofing membranes have the capability to be utilized on wood surfaces. These membranes are highly adaptable and can be applied to various materials, including wood. Their main purpose is to establish a safeguarding barrier that hinders water infiltration, thus preventing moisture-related harm such as decay, distortion, or the growth of mold. By correctly applying waterproofing membranes, wood surfaces can be effectively sealed, rendering them impervious to water absorption and enhancing their longevity and robustness. It is crucial to select a waterproofing membrane that is specially developed for wood applications and adhere to the manufacturer's guidelines for appropriate application and upkeep.

- Q: Are waterproofing membranes suitable for balconies and terraces?

- Yes, waterproofing membranes are suitable for balconies and terraces as they provide an effective barrier against water infiltration, protecting the underlying structure from potential damage caused by moisture.

- Q: Are waterproofing membranes resistant to gasoline vapors?

- Yes, waterproofing membranes are generally resistant to gasoline vapors. They are designed to create a barrier against moisture and other liquids, including gasoline and its vapors.

- Q: How does a waterproofing membrane prevent water infiltration?

- Waterproofing membranes are specialized barriers used to prevent water from infiltrating structures like buildings or underground structures. They are typically made of synthetic materials like rubber, PVC, or bitumen, known for their water-resistant properties. The primary purpose of a waterproofing membrane is to establish a physical barrier that water cannot penetrate. It is applied to the exterior surface of the structure, creating a continuous layer that tightly adheres to the substrate. This effectively blocks water from seeping through cracks, joints, or porous surfaces, redirecting it away from the structure. One of the main ways in which a waterproofing membrane prevents water infiltration is by providing a seamless and impermeable layer. This means there are no gaps or weak points that would allow water to enter. Multiple layers of the membrane are often applied to ensure a durable and watertight seal, effectively stopping any water from penetrating the structure. Furthermore, waterproofing membranes are designed to withstand water pressure. They can endure the hydrostatic pressure exerted by water and prevent it from entering the structure. This is particularly crucial for below-ground structures like basements or foundations, which are prone to groundwater infiltration. In addition, waterproofing membranes often come with additional features to enhance their effectiveness. These may include additives or properties that improve flexibility, durability, or resistance to environmental factors like UV rays or chemicals. These properties ensure the membrane remains intact and functional over time, effectively preventing water infiltration. To sum up, waterproofing membranes prevent water infiltration by establishing a seamless and impermeable barrier that water cannot penetrate. They are designed to withstand water pressure and are applied to the exterior surface of structures to block water from seeping through cracks, joints, or porous surfaces. With their additional features, waterproofing membranes provide long-term protection against water infiltration.

- Q: What are the advantages and disadvantages of waterproofing membrane?

- The advantages of the membrane waterproof, such as: the construction is convenient, the construction period is short, not need to be cured after forming, is not affected by the temperature, the environmental pollution is small, the layer thickness is easy to hold and hold the fortification meter, the material is calculated accurately, the site management is convenient, jerry, a uniform layer thickness, the base layer can effectively overcome stress empty shop (the base layer occurs at the time maintaining the overall efficiency of large cracks waterproof layer).

- Q: Are there any limitations to using a waterproofing membrane?

- Yes, there are some limitations to using a waterproofing membrane. One limitation is that the membrane can be punctured or damaged during installation, which can compromise its effectiveness. Additionally, waterproofing membranes may not be suitable for all types of surfaces or structures, and certain conditions such as extreme temperatures or excessive movement can affect their performance. Moreover, the lifespan of a waterproofing membrane can vary depending on factors like maintenance, exposure to UV rays, and overall wear and tear.

Send your message to us

PVC Waterproofing Membrane with Single-Side Compounded with Fiber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords