PVC Roofing Membrane PE membrane SBS waterproof Membrane In Chinese Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Self-adhesive polymer modified bitumen membrane systems is based on synthetic rubber and resin modified asphalt by adding activity agent, polyester felt or fiberglass felt, polyethylene as the child-based, polyethylene film as surface materials, or without membrane (double-sided self-adhesive), using silicone oil separated anti-adhesive membrane.

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Characteristic

1.high adhesive.

2.anti distortion.

3.Non toxic,tasteless,environmentally friendly.

4.Not strict requirement for the substrate, save time

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application method:

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

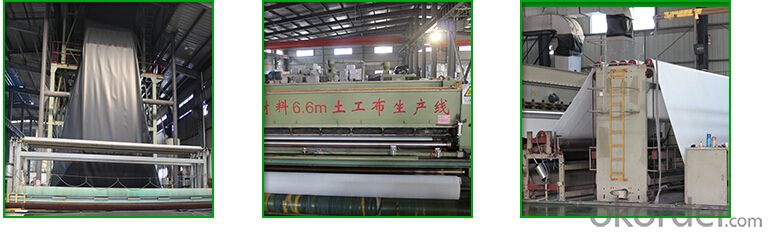

Product line&test

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Why choose us ?

We have 20 years manufacturer experience

10000-30000 square meter factory size,more than 10 production lines

We will be your best partner,provide high quality products with CE,ISO,SGS

approved in competitive prive,sincerely hope to make a win-win cooperation with you.

FAQ

- Q: Can a waterproofing membrane be used on glass surfaces?

- Using a different grammar and expressions: It is not possible to utilize a waterproofing membrane on glass surfaces. Waterproofing membranes are specifically formulated to adhere to surfaces that are porous and rough, such as concrete, wood, or metal. Glass surfaces, on the other hand, are smooth and non-porous, which poses challenges for proper adhesion of the membrane and its ability to establish an effective waterproof barrier. Furthermore, glass surfaces are inherently waterproof, rendering additional waterproofing measures generally unnecessary.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic activity can cause significant ground movement and structural vibrations, which can potentially compromise the integrity of the membrane. Therefore, it is crucial to select a membrane that is specifically designed and tested to withstand seismic conditions. Additionally, proper installation techniques and materials, such as reinforced membranes and flexible adhesives, should be used to ensure the membrane remains intact during seismic events.

- Q: Does a waterproofing membrane require any specific surface preparation?

- Yes, a waterproofing membrane does require specific surface preparation before installation. The success and effectiveness of the membrane largely depend on the quality and condition of the surface it is applied to. Firstly, the surface needs to be clean and free from any dirt, debris, oil, grease, or loose particles. This can be achieved by thoroughly cleaning the surface using a pressure washer, scrub brush, or appropriate cleaning agents. Any existing coatings or sealants should also be removed to ensure proper adhesion of the membrane. Secondly, the surface should be smooth and even. Any uneven areas, cracks, or holes should be repaired and leveled before applying the membrane. This can be done by filling the cracks or holes with a suitable filler or patching compound and smoothing it out to create a uniform surface. Thirdly, the surface should be dry. Moisture can compromise the adhesion and effectiveness of the waterproofing membrane. Therefore, it is important to ensure that the surface is completely dry before starting the installation. This may require allowing the surface to air dry or using appropriate drying methods such as fans or dehumidifiers. In addition to these general surface preparations, specific types of waterproofing membranes may have additional requirements. For example, some membranes may require a primer to be applied on the surface before installation. It is essential to follow the manufacturer's instructions and recommendations for the specific membrane being used. Overall, proper surface preparation is crucial for the success of a waterproofing membrane installation. It ensures optimal adhesion, durability, and performance of the membrane, ultimately preventing water penetration and protecting the underlying structure.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Specific safety precautions are necessary when installing a waterproofing membrane. Consider the following key precautions: 1. Personal Protective Equipment (PPE): Installers must wear appropriate PPE, such as gloves, safety glasses, and protective clothing, to avoid skin contact with the membrane and potential chemical hazards. 2. Adequate Ventilation: Ensure that the installation area has proper ventilation to prevent the accumulation of fumes or vapors. If working in a confined space, use ventilation systems to eliminate any potentially harmful gases or odors. 3. Hazardous Chemicals: Some waterproofing membranes contain hazardous chemicals or solvents. Installers should carefully read and adhere to the manufacturer's instructions for handling and using these products. Proper storage, handling, and disposal of chemicals are crucial to prevent accidents or environmental contamination. 4. Slips and Falls: The surface can become slippery during installation, particularly when applying the membrane on wet surfaces. Installers should take precautions to maintain stability and utilize safety equipment like harnesses or guardrails when working at heights to prevent falls. 5. Heat Hazards: Proper installation of certain waterproofing membranes requires the use of heat. Installers should exercise caution when working with heat sources such as torches or heat guns to prevent burns or fire hazards. Keep fire extinguishers readily available and ensure that personnel receive adequate training on fire safety protocols. 6. Electrical Safety: Waterproofing membranes might be installed in areas where electrical systems are present. Installers should exercise caution when working near live electrical wires or outlets and adhere to proper electrical safety procedures to prevent electric shocks or fires. It is crucial for installers to undergo comprehensive training and diligently follow all safety guidelines provided by the manufacturer. This will help minimize the risk of accidents, injuries, or property damage during the installation process.

- Q: Can a waterproofing membrane be used for a swimming pool liner?

- Yes, a waterproofing membrane can be used for a swimming pool liner. In fact, it is a common and effective solution for creating a watertight seal in swimming pools. Waterproofing membranes are designed to be durable and resistant to water penetration, making them an ideal choice for lining pools. They provide a protective barrier that prevents water from seeping into the ground, which can cause structural damage and leaks. Additionally, waterproofing membranes can be customized to fit any pool size and shape, ensuring a perfect fit and maximum waterproofing performance. Overall, using a waterproofing membrane as a swimming pool liner is a reliable and cost-effective solution to maintain the integrity and longevity of the pool structure.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Terraces and patios can benefit greatly from the application of a waterproofing membrane. To avoid water damage and leakage, it is highly recommended to use this protective layer in these areas. Given that terraces and patios are exposed to different weather conditions, such as rain and snow, moisture can easily seep into the underlying structure. To counteract this issue, a waterproofing membrane acts as a barrier, preventing water from infiltrating the surface and safeguarding the integrity of the terrace or patio. This solution not only extends the lifespan of the structure but also prevents costly repairs in the future. Moreover, the use of a waterproofing membrane contributes to the creation of a more comfortable and functional space, as it eliminates the risk of water accumulation and potential slip hazards. All in all, investing in a high-quality waterproofing membrane is a wise choice for those seeking to protect their terrace or patio from water damage.

- Q: Can a waterproofing membrane be applied on both interior and exterior surfaces of a structure?

- Both interior and exterior surfaces of a structure can receive the application of a waterproofing membrane. These membranes are designed to form a barrier that prevents water from infiltrating the structure. Regardless of whether it is applied internally or externally, the membrane serves the same purpose of keeping water out and safeguarding the structure against moisture damage. In the case of basements, crawl spaces, or other areas where water intrusion from the inside is a worry, interior waterproofing membranes are typically utilized. On the other hand, exterior waterproofing membranes are commonly used on foundation walls, below-grade areas, or building envelopes to stop water from seeping into the structure. It is crucial to select the appropriate type of waterproofing membrane based on the specific requirements and conditions of the structure.

- Q: Can a waterproofing membrane be used for bridge or tunnel waterproofing?

- Bridge or tunnel waterproofing can be achieved by using a waterproofing membrane. These membranes are designed to create a barrier that prevents water infiltration and are commonly employed in various construction applications, including bridges and tunnels. They are typically composed of materials like bitumen, PVC, or EPDM, which offer excellent resistance to water penetration. Bridge and tunnel structures are constantly exposed to harsh environmental conditions such as water seepage, which can cause corrosion and structural damage over time. By applying a waterproofing membrane to the surface of the bridge or tunnel, it effectively prevents water from entering the structure, safeguarding it against deterioration and prolonging its lifespan. Waterproofing membranes specifically engineered for bridges and tunnels are capable of withstanding heavy traffic loads, weathering, and other environmental factors. They are designed to be durable, flexible, and resistant to cracking, ensuring long-term protection. Additionally, these membranes typically possess UV resistance qualities, enabling them to maintain their integrity even when exposed to sunlight. Moreover, there are various installation methods for waterproofing membranes, depending on the specific requirements of the bridge or tunnel project. They can be applied as liquid coatings, sprayed or rolled on, or installed in prefabricated sheets. This versatility allows for customization and efficient installation tailored to the unique characteristics of each structure. In summary, utilizing a waterproofing membrane is a reliable and effective solution for bridge and tunnel waterproofing. It establishes a dependable barrier against water infiltration, shielding the structure from corrosion and deterioration, and extending its lifespan.

- Q: Can a waterproofing membrane be used for a hotel swimming pool area?

- Yes, a waterproofing membrane can be used for a hotel swimming pool area. The membrane will provide a barrier against water penetration, helping to keep the pool area dry and prevent any potential damage to the underlying structure.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Indeed, it is possible to utilize a waterproofing membrane on both the inner and outer walls. Said membranes are specifically devised to thwart the infiltration of water or moisture into the walls, irrespective of their positioning within a structure. Typically, these membranes are crafted from materials like rubber, modified bitumen, or liquid-applied coatings, which serve as a potent barricade against water seepage. Through the application of a waterproofing membrane on both the interior and exterior walls, one can guarantee the prolonged defense of the building against water-related harm, such as mold proliferation and other moisture-induced predicaments.

Send your message to us

PVC Roofing Membrane PE membrane SBS waterproof Membrane In Chinese Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords