Plastic Tubes - PVC Pressure Pipe (ASTM Sch 80) 0.63-1.6MPa, GB/T10002.1-2006

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of PVC Pipe :

Material: Virgin Rigid PVC resin, no recycle material

Process: vacuum forming extrusion

Color: various colors, we can make color according to Panton card No.

Application:construction, home decoration, stationery&toy, advertising, ornament, etc.

Common Feature: high glossy, water proof, damp proof, termite proof, shock proof, fire retardant, Maintenance free, light weight ,easy to install, economical, durability, recyclable

2.Features of PVC pipes :

1) Light weight, easy to load and unload: PVC pipe is very light, convenient to handle loading unloading, and installing.

2) Good chemicals and drugs resistance: PVC pipe has its excellent resistance to the erosion caused by acids and alkalines, a great help to the chemical industries.

3) Small resistance to fluidity: The smooth surface reduces resistance to the fluids. Its roughness coefficient is only 0.009, much less than other pipes, Under same discharges, smaller cabibre of the pipe can be uesd.

4) Strong mechanical strength: Good resistance to water pressure, outside impact and pressure, is satisfied under any conditions.

5) Water quality unaffected: The solution tests on the PVC pipe show no affect on water quality when the water flows through is. It is considered the best piping material for running water works.

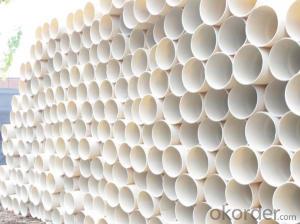

3.PVC Pipe Images:

4.Specifications of the PVC pipe:

1) Material: pvc pipe unplasticized polyvinyl chloride

2) Standard: GB, ISO9001, ISO14001

3) Color: white pvc pipe, grey pvc pipe , etc.

4) Specific Gravity:g/cm3, 20(C): 1.35 - 1.55

5) Dichloromethane Resistance Test: No attack

6) Falling Weight Impact Test: TIR, %, 0(C) <=10< span=""><>

7) Tensile Yield Strength: Mpa >=40

5.FAQ

Q:What is you MOQ?

A:As customer’s request.

Q:What is the production ability? or delivery time?

A:Our production ability support 40HQ order finish in one week.

Q:What is your payment?

A:TT or CC.

Q:For urgently doubts,who online?

A:Sales and marketing Manager 24hours online service.

- Q: Where is orifice tube on 97 blazer?

- The plastic expansion tube contains a fixed diameter tube with a mesh filter screen at either end. It is located in the evaporator inlet pipe. It creates a restriction to the high-pressure liquid refrigerant in the liquid line, metering the flow of refrigerant to the evaporator as a low-pressure liquid. When the engine is turned OFF with the air conditioning operating, the refrigerant in the system will flow from the high-pressure side of the expansion tube (orifice) to the low-pressure side until the pressure is equalized. This may be detected as a faint sound of liquid flowing (hissing) for 30 to 60 seconds. This is a normal condition. When system diagnostics indicate a restricted expansion tube, it may not be necessary to replace it. Metal chips, flakes, or slivers found on the screen may be removed with compressed air. The expansion tube may be reused if: * The plastic frame is not broken. * The expansion tube is not damaged or plugged. * The screen material is not torn. * The screen is not plugged with fine gritty material.

- Q: GFs birthday coming up and I want to give her something special... any suggestions as to what I can make?

- some dough to get a real gift. ^_^

- Q: Seems to me they could be half the size they are and would still be perfectly usable.

- There are so many other problems in this world. Bigger ones. Plastic is plastic man. If the tube was half the size, that's half the stuff, so you'd buy twice as much. Same amount of plastic. More work in production. Pointless. *shrugs*

- Q: Is there an easy way to remember the color tubes (phlebotomy) and what test they are needed for?

- This Site Might Help You. RE: Is there an easy way to remember the color tubes (phlebotomy) and what test they are needed for?

- Q: Are plastic tubes resistant to scratching?

- Yes, plastic tubes are generally resistant to scratching.

- Q: What's the name of that plastic tube used to fold stars?

- (1) the straw is bent back;(2) turn left pipe to the lower right;(3) turn the upper pipe to the left;(4) turn the two pipes together;(5) wrap the left tube over the right tube and fold it to the lower right;(6) wrap the upper tube over the lower tube;(7) the two pipes are turned together, with steps (4), repeating steps (4), (5), (6), (7);(8) stick the first angle close to the two pipes;(9) wrap the left tube over the first corner;(10) turn the top pipe down to the bottom;(11) repeat steps (9), (10) fold the tube to the end;(12) pass one of the tubes through the stars;(13) trim after tensioning;(14) complete

- Q: Why, in general, the strong tube is plastic tubes, weak tubes are metal tubes?

- The metal tube can be grounded to shield, eliminate interference, and reduce the electromagnetic interference between the weak current

- Q: I need to find a round, plastic jar that is 4 1/2 inches in diameter and 4 3/4 high. Does anyone know where I can find something like this?

- I'd bring a tape rule to your local grocery store.

- Q: Can plastic tubes be used for craft projects like DIY lamps?

- Yes, plastic tubes can definitely be used for craft projects like DIY lamps. They are lightweight, flexible, and can be easily cut and shaped to fit various designs. Additionally, they come in a variety of colors and sizes, allowing for creativity and customization in crafting unique lamps.

- Q: Ok so I now have all my gear to go bass fishing and im using some soft plastic tubes and brush hogs mainly using a carolina rig. I will be fishing in lakes for small mouth and large mouth. After casting what are some good methods of retrieval for the lures other than just reeling it in. for instance should i pause for so many seconds after the bait hits the water then reel? or should i reel then pause for so many seconds then reel again?

- Tubes I use a tube jig and....just jig it. Brush hogs I'd rig texas style and pitch it into weeds.

Send your message to us

Plastic Tubes - PVC Pressure Pipe (ASTM Sch 80) 0.63-1.6MPa, GB/T10002.1-2006

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords