PVC High Polymer Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of PVC membrane:

|

20m/roll or customized |

Width | 2.05m |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm or customized |

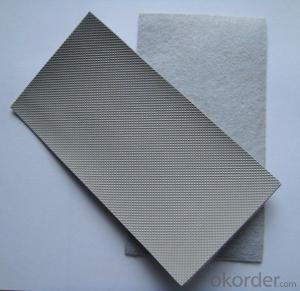

Type | Polyester scrim reinforced PVC waterproofing membrane |

If Exposed | Exposed and Non-exposed |

Color | All accepted |

Composition:

The P series waterproofing membrane is a high-quality,thermoplastic PVC membrane with a polyester scrim reinforcement. We solved the problem of extraction and migration of PVC plasticizer in production, make the products the best durability in thermoplastic waterproofing.

Features and Benefits:

l High Strength

l Hot-air welded seams for long-term performance

l Proven membrane performance

l Excellent resistance to plasticizer extraction and migration performance.

Packaging:

The rolls of P series waterproofing membrane are wrapped in a protective film and strapped to a wood pallet. The P series waterproofing membrane lengths of 15m, 20m, 25m, widths of 1.03m, 2.05m and thicknesses of 1.20mm, 1.50mm, 1.80mm, 2.00mm or customized according to customers requirements.

Installation:

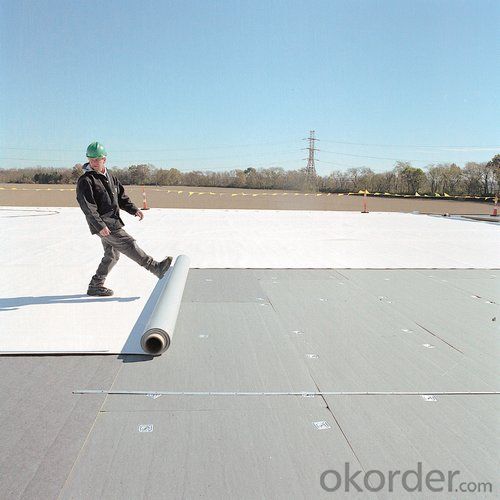

The P series waterproofing membrane is installed by a Magical Stone Authorized Applicator.

P series is rolled out onto the insulation board or acceptable substrate,fastened to the surface and heat-welded together by trained operators using Magical Stone's hot-air welding equipment.

Availability:

The P series waterproofing membrane is available directly from Magical Stone Autherized Applicators. Contact your Magical Stone Regional Office or visit our website for further information.

Warranty:

Upon successful completion of the installed surface by the Magical Stone Authorized Applicator, Magical Stone can provide a Warranty to the Building Owner via the Authorized Applicator.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be pre-fabricated or pre-made for easy installation?

- Yes, a waterproofing membrane can be pre-fabricated or pre-made for easy installation. In fact, many manufacturers offer pre-made waterproofing membranes that are specifically designed to simplify the installation process. These membranes are typically manufactured in controlled factory conditions, ensuring consistent quality and reducing the potential for errors during installation. Pre-fabricated waterproofing membranes are made from various materials such as bitumen, PVC, EPDM, or TPO, and come in different forms such as sheets or rolls. They are designed to be easily transported and installed on-site. The advantages of using pre-fabricated waterproofing membranes include increased efficiency, reduced labor costs, and improved installation quality. By eliminating the need for on-site fabrication, contractors can save time and resources. Additionally, pre-made membranes often come with detailed installation instructions, making it easier for contractors to ensure proper installation. Furthermore, pre-fabricated waterproofing membranes can be tailored to fit specific project requirements, such as size, shape, or slope. This customization helps to ensure a seamless and effective waterproofing solution. Overall, using pre-fabricated or pre-made waterproofing membranes can significantly simplify the installation process and provide a reliable and durable waterproofing solution for various applications, including roofs, basements, and foundations.

- Q: Are waterproofing membranes effective against mold and mildew?

- Waterproofing membranes effectively combat mold and mildew by acting as a barrier against water infiltration. This barrier reduces moisture, which is essential for mold and mildew growth. By sealing the surface, these membranes prevent water intrusion and the subsequent moisture buildup that fosters mold and mildew formation. Some waterproofing membranes even have anti-microbial properties that specifically hinder the growth of mold and mildew. Nevertheless, it is crucial to remember that in order to achieve long-term prevention, proper building ventilation and maintenance are also imperative, despite the significant risk reduction provided by waterproofing membranes.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to provide a protective barrier against water infiltration, which is crucial for the longevity and maintenance of buildings. They are particularly effective in areas prone to heavy rainfall or where water exposure is a concern, making them suitable for shopping malls and commercial buildings where water damage can be costly and disruptive.

- Q: Can a waterproofing membrane be used on precast gypsum surfaces?

- Yes, a waterproofing membrane can be used on precast gypsum surfaces. This membrane acts as a barrier to prevent water penetration and can be applied to protect the gypsum surface from moisture damage.

- Q: How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- A waterproofing membrane is designed to accommodate the movement of a building caused by settling or seismic activity. It offers a flexible and elastic barrier that can stretch and contract with the building's movements, preventing any water penetration. When a building settles or experiences seismic activity, it can undergo significant structural movements. These movements can cause cracks, shifts, or changes in the building's foundation, walls, or floors. Without proper waterproofing, water can seep through these cracks or gaps, leading to water damage, mold growth, and structural deterioration. To address this, waterproofing membranes are typically made of materials that have excellent elongation and recovery properties. Elongation refers to the membrane's ability to stretch without tearing, while recovery refers to its ability to return to its original shape after being stretched. This flexibility allows the membrane to move with the building, rather than resisting or cracking under the stress. Moreover, waterproofing membranes are installed in a way that allows for horizontal and vertical movement. They are often applied in layers, with overlapping seams to create a continuous barrier. This layered approach accommodates any potential shifts or settlements in the building by allowing the membrane to move and adjust accordingly. In areas prone to seismic activity, additional measures may be taken to reinforce the waterproofing system. These can include the use of specialized membranes that have higher elongation and recovery properties or the incorporation of reinforcement elements such as fabric or mesh to enhance the membrane's ability to handle movement. In summary, a waterproofing membrane is specifically designed to handle the movement of a building caused by settling or seismic activity. Its flexibility, elongation, and recovery properties, along with proper installation techniques, allow it to accommodate the building's movements while maintaining a watertight barrier.

- Q: Can a waterproofing membrane be used for a parking lot?

- Indeed, a parking lot can benefit greatly from the utilization of a waterproofing membrane. Specifically engineered to create a safeguard against water infiltration, this remarkable membrane can be skillfully applied to a myriad of surfaces, encompassing parking lots. Its primary purpose is to thwart water-related damages, such as the formation of cracks and the degradation caused by the dreaded freeze-thaw cycles, ultimately leading to an elongated lifespan for the parking lot. Moreover, the implementation of a waterproofing membrane in a parking lot not only aids in the prevention of water leakage into the subbase, but it also fortifies its stability, effectively mitigating the possibility of exorbitant repairs. This intelligent investment not only bolsters the durability and longevity of the parking lot but also curtails the necessity for excessive maintenance efforts. In essence, the utilization of a waterproofing membrane for a parking lot serves as a prudent decision, ensuring enhanced endurance and reduced upkeep requirements.

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are designed to be resistant to frost damage. They are typically made from durable materials that can withstand freezing temperatures without cracking or deteriorating.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Yes, a waterproofing membrane can be used on precast metal surfaces. Waterproofing membranes are designed to provide a protective layer that prevents water penetration and can be applied to various types of surfaces, including precast metal. These membranes are typically composed of materials such as bitumen, liquid-applied coatings, or synthetic rubber, which create a barrier against water and moisture. By applying a waterproofing membrane to precast metal surfaces, it can help to prevent corrosion, protect against water damage, and enhance the durability and longevity of the metal structure. However, it is important to ensure that the chosen waterproofing membrane is compatible with the specific type of precast metal surface and that proper surface preparation and application techniques are followed to ensure optimal performance.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Yes, a waterproofing membrane can be used on both interior and exterior walls. The membrane helps prevent water penetration, providing protection against moisture for both sides of the wall.

- Q: How long does it take for a waterproofing membrane to cure?

- The time it takes for a waterproofing membrane to cure can vary depending on various factors such as the type of membrane, environmental conditions, and the specific product being used. Generally, most waterproofing membranes require at least 24 to 48 hours to fully cure. During this time, the membrane undergoes a chemical reaction that allows it to form a durable, impermeable barrier. However, it is important to note that curing times can be influenced by factors like temperature, humidity, and the thickness of the applied membrane. It is always recommended to follow the manufacturer's instructions and allow ample time for the membrane to cure before subjecting it to any stress or water exposure.

Send your message to us

PVC High Polymer Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords