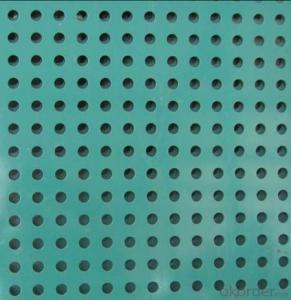

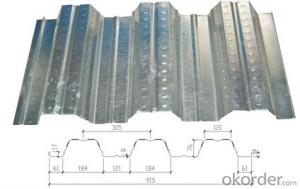

PVC Foam Sheet Decorative Perforated Sheet Metal Panels

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

PVC Foam Sheet Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

Product Specification

Size:1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Usage Life: more than 50 years

PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

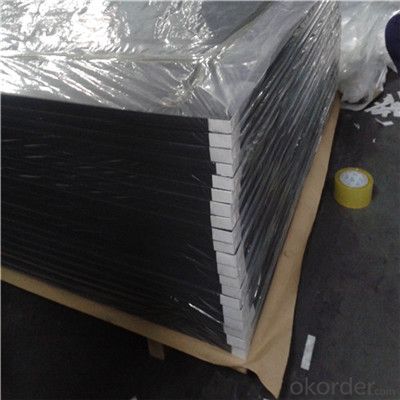

PVC Foam Sheet pictures

Packing

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Could you provide samples?

A: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

- Q: How to do inventory management

- Hello, sheet metal warehouse Invoicing, and other commodity circulation industry is the same. I give you a Invoicing management software information, you can see, you can use the next software management. The business model provides users with a more comprehensive business, simple financial integration management solutions, including order management, purchasing management, sales management, inventory management, financial management, management, freight management, fixed asset management, Salary management, rework management, member management and customer management. Its more cost-effective, faster, more adaptable, more flexible operation. "Management is more comprehensive, more convenient to use." Is the largest feature of Simba business, especially for small and medium-sized enterprises in China's management status and retail business management status quo.

- Q: F grade sheet and EO-class plate, what is the difference between these two, Guiqiu master answer, buy a furniture to the market a question, really a headache? Which is good?

- These are the measures that measure the amount of formaldehyde released by the furniture and are environmentally friendly F4 star is a new upgrade of environmental standards, compared to E0 should be more advantages. ? The so-called F4 star standard, in fact, Japan's "F ☆ ☆ ☆ ☆ certification standard" F4 Star "is the highest standard of Japanese floor standards of health, but also considered the world's most healthy floor standards.If the usual E1, E0 Standard, then the "F3 star" is equivalent to the national E0 level standard, the proposed limit the use of area, "F4 star" is much higher than the "F3 star", the use of unlimited area. The standard applies to sheet, floor, Cabinets, furniture and other wooden building materials products.

- Q: What are the advantages of nylon plates compared to other plastic sheets?

- The nylon series is the most important engineering plastic. The product is widely used, covering almost every area, is the five most widely used engineering plastics varieties Nylon board according to the production process is divided into two kinds of extrusion and casting. Extrude the nylon plate 1, nylon 6 (white): The material has the most comprehensive performance, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance. These features, coupled with good electrical insulation and chemical resistance, make nylon 6 a "universal grade" material for the manufacture of mechanical structural parts and maintainable parts. 2, nylon 66 (cream): Compared with nylon 6, its mechanical strength, stiffness, heat and wear resistance, creep resistance better, but the impact strength and mechanical damping performance degradation, very suitable for automatic lathe Machining. 3, nylon 4.6 (reddish brown): Compared with ordinary nylon, nylon 4.6 is characterized by strong rigid retention, good creep resistance, in a wide temperature range, more heat aging, therefore, nylon 4.6 for Nylon 6, nylon 66, POM and PET in the stiffness, creep resistance, heat aging, fatigue strength and wear resistance can not meet the requirements of the "higher temperature field" (80 -150 ℃) 4, nylon 66 + GF30 (black): Compared with pure nylon 66, this nylon filled with 30% glass fiber reinforced, its heat resistance, strength, stiffness. Creep resistance and dimensional stability, wear resistance and other properties have improved, it is the maximum allowable use of high temperature. 5, nylon 66 + MOS2 (gray black): This nylon filled with molybdenum disulfide, compared with nylon 66, its rigidity, hardness and dimensional stability has improved, but the impact strength has declined, molybdenum disulfide Of the grain formation effect to improve the crystal structure, so that the material bearing and wear resistance are improved.

- Q: The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q: What kind of auxiliary materials / details of the woodworking board shop?

- F30 most commonly used, mosquito nails, J1010 those, there are F20,25, ST38,50, T50, self-tapping screws, slotted tapping screws, glass glue, foam glue, Handle, hardware (track, lock, hinge, door suction, bed hanging ..)) ... Ceiling: the main vice-long, screw, 8 sets! Gypsum board, silicon calcium board! The a lot,,

- Q: What kind of plate is the decoration with the density board?

- In daily life, people commonly referred to as the MDF, but also can be called fiber board, it is made of wood fiber, or other plant fiber as raw materials, plus urea-formaldehyde resin, or other appropriate adhesive made of man-made sheet. Since it is called MDF, then it must have a certain density. Therefore, according to their density, we can divide the MDF into three categories: low density board, medium density board and high density board. In view of the MDF texture is soft, and the impact resistance is relatively strong, but also relatively easy to re-processing, so abroad, MDF is a very good material making furniture. However, because the domestic demand for high-density board is much lower than the international standard, therefore, the quality of China's MDF should also be further improved.

- Q: Are plates p2 and e0 almost?

- In the purchase process, as long as optimistic about the level of formaldehyde release board on the line. E0 best, E1 times, E2 has been rarely used. Southeast wood manufacturers have super E0 board, formaldehyde release even less, but also by the United States California certification p2 plate. CAPB P2 level is higher

- Q: What is the standard size of the various plates? Decoration in a variety of plate specifications

- Furniture plate commonly used specifications: 2440 * 1220mm commonly used thickness: 3mm, 5mm, 6mm, 9mm, 12mm, 15mm, 16mm, 18mm, 25mm.

- Q: What is the overall thickness of the wardrobe sheet?

- Under normal circumstances is 15mm-18mm; the production of the overall wardrobe of the main woodworking board, particleboard, fiberboard, solid wood finger plate and multi-layer solid wood, solid wood particle board; fiber board thickness of 3mm, 6mm, The use of multi-layer solid wood more.

- Q: Many types of flooring, which OKorder is suitable for several floor plate?

- Ficus aurantium, Indian eggplant, ash wood, round beans, two wings beans, oak (white oak) Pineapple (small pineapple) Features: heavy, relatively hard. Stability is very good. Affordable choice. Description: The color of dark reddish brown wood, texture dense and strong, with curved curved black wood texture, the island people often used to make piling boat keel and semi-circular bracket. Wood adhering to the fine characteristics of pineapple grid, is a can be used for geothermal and has a variety of color selection of subtropical wood species. Is the ideal alternative to pineapple grid, also known as small pineapple grid. On behalf of the brand: Kyrgyzstan (mid-range), Huaming (old brand of good service), Li Feng (first-line brand) Merlin wood features: heavy, more hard wear, anti-termite moisture. Stability is very good, are cost-effective species, once popular. Indonesia to reduce the cutting prices have an upward trend. Brief introduction: 1, Indian eggplant is growing in the paradise rain forest in the precious tropical hardwood, it takes 80 years to mature, in each hectare virgin forest can only find 1-5 trees.

Send your message to us

PVC Foam Sheet Decorative Perforated Sheet Metal Panels

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords